Method for prolonging cleaning period of immersed ultra filtration membrane

A cleaning cycle and ultrafiltration membrane technology, applied in ultrafiltration, chemical instruments and methods, membrane technology, etc., can solve the problems of short cleaning cycle, insufficient cleaning, and high degree of membrane fouling, improve water production rate and reduce membrane pollution. Contamination, the effect of prolonging the cleaning cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

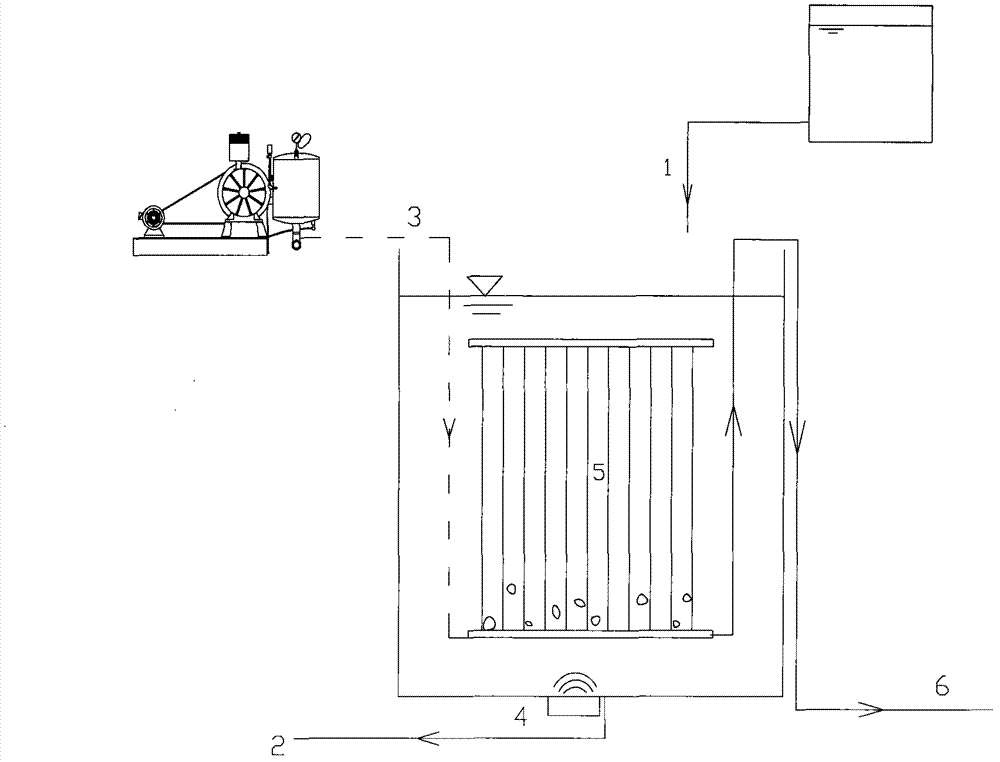

Image

Examples

Embodiment 1

[0036] The submerged ultrafiltration membrane filters the effluent of a sedimentation tank of a water plant, and the turbidity of the membrane tank influent is 2.87-3.24NTU, COD Mn The content is 2.89-3.04mg·L -1 , the water temperature is 15.5-16.8°C, and the membrane flux is 25L m -2 h -1 . No destabilizer is added to the water, the reflux ratio is 10%, and the aeration intensity is 45m 3 m -2 h -1 , the aeration time is 3min, the aeration interval time is 30min, the ultrasonic and aeration are carried out simultaneously, the ultrasonic power consumption is 40kHz, and the sound intensity is 50W·m -2 . After the membrane runs for 150 hours, the flux drops to 10L m -2 h -1 , down 60%. At this time, stop the filtration, and clean and discharge the membrane.

Embodiment 2

[0038] The submerged ultrafiltration membrane filters the effluent of a sedimentation tank of a water plant, and the turbidity of the membrane tank influent is 2.79-3.12NTU, COD Mn The content is 2.91-3.14mg·L -1 , the water temperature is 14.5-17.2°C, and the membrane flux is 25L m -2 h -1 . No destabilizer is added to the water, the reflux ratio is 10%, and the aeration intensity is 45m 3 m -2 h -1 , the aeration time is 3min, the aeration interval time is 30min, and the ultrasonic wave is not used. After the membrane runs for 90 hours, the flux drops to 10L m -2 h -1, down 60%. At this time, stop the filtration, and clean and discharge the membrane.

Embodiment 3

[0040] The submerged ultrafiltration membrane filters the effluent of a sedimentation tank in a water plant, and the turbidity of the influent water in the membrane tank is 2.85-3.37NTU, COD Mn The content is 2.69-2.97mg·L -1 , the water temperature is 16.5-17.2°C, and the membrane flux is 30L m -2 h -1 . No destabilizing agent is added to the water, the reflux ratio is 10%, no aeration is used, the ultrasonic power consumption is 40kHz, and the sound intensity is 50W·m -2 , Ultrasound interval time is 30min. After the membrane runs for 60 hours, the flux drops to 15L m -2 h -1 , down 50%. At this time, stop the filtration, and clean and discharge the membrane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com