Preparation method of anaerobic tin based solder alloy

A technology of tin alloys and alloys, which is applied in the field of preparation of oxygen-free tin-based solder alloys, can solve the problems of increased oxygen content, increased oxygen content, and unfavorable use of products, and achieve the effect of solving the problem of increased oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

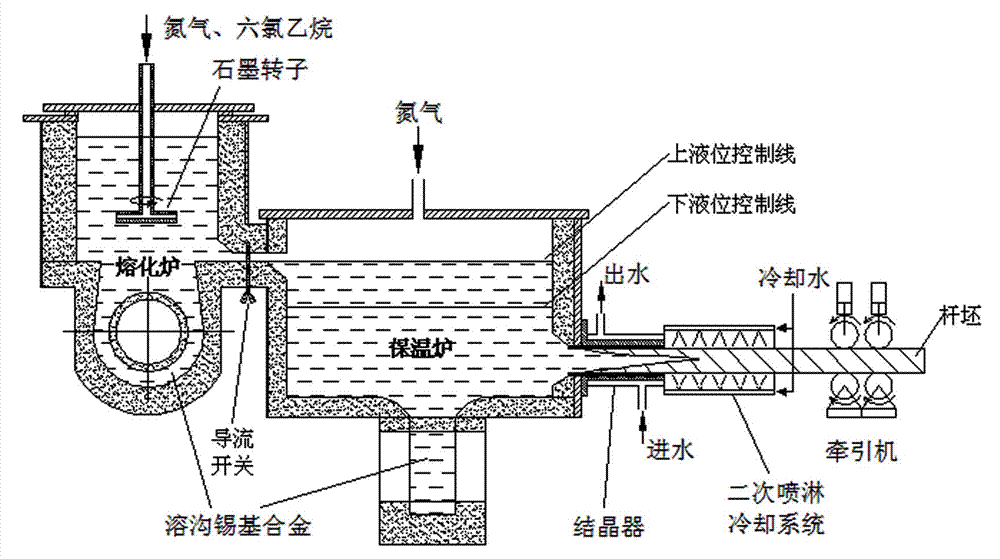

Embodiment 1

[0015] Embodiment 1: Apply the method of the present invention to produce SnCu0.7 lead-free solder. First, qualified tin raw materials and tin-copper intermediate alloy materials are prepared in a certain proportion, weighed, and put into a power frequency induction furnace for melting. Set the temperature of the power frequency induction furnace to 400°C, then turn on the graphite rotor, set the speed to 80 rpm, turn on the quantitative pump, blow nitrogen (0.3MPa) and hexachloroethane (0.2%) into the tin liquid, after 40min , remove the surface scum. Then open the diversion switch to guide the liquid into the holding furnace until the upper liquid level control line, and close the diversion switch. Set the temperature of the holding furnace at 380°C, turn off the cooling water of the crystallizer, put a draw rod into the crystallizer and gently tap it into the crystallizer, slowly guide the draw rod to the traction wheel with pliers, press the traction wheel, and start the ...

Embodiment 2

[0016] Embodiment 2: Apply the method of the present invention to produce SnAg3.0Cu0.5 lead-free solder. Qualified tin raw materials, tin-copper intermediate alloy materials, and silver raw materials are prepared in a certain proportion, weighed, and put into a power frequency induction furnace for melting. Set the temperature of the power frequency induction furnace to 380°C, then turn on the graphite rotor, set the speed to 80 rpm, turn on the quantitative pump, blow nitrogen (0.3MPa) and hexachloroethane (0.2%) into the tin liquid, after 40min , remove the surface scum. Then open the diversion switch to guide the liquid into the holding furnace until the upper liquid level control line, and close the diversion switch. Set the temperature of the holding furnace at 350°C, turn off the cooling water of the crystallizer, put a draw rod into the crystallizer and gently tap it into the crystallizer, slowly guide the draw rod to the traction wheel with pliers, press the traction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com