Method for preparing PVP (polyvinyl pyrroloidone)/FF composite nano-fiber film by static spinning preparation

A composite nanofiber, electrospinning technology, applied in spinning solution preparation, textiles and papermaking, non-woven fabrics, etc., can solve the problems of small molecular weight, low solution concentration, difficult electrospinning, etc., achieving simple operation and less time-consuming , good degradability and biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Put the mixture of methanol and N,N-dimethylacetamide (DMAc) at a volume ratio of 85:15 into the reaction vessel;

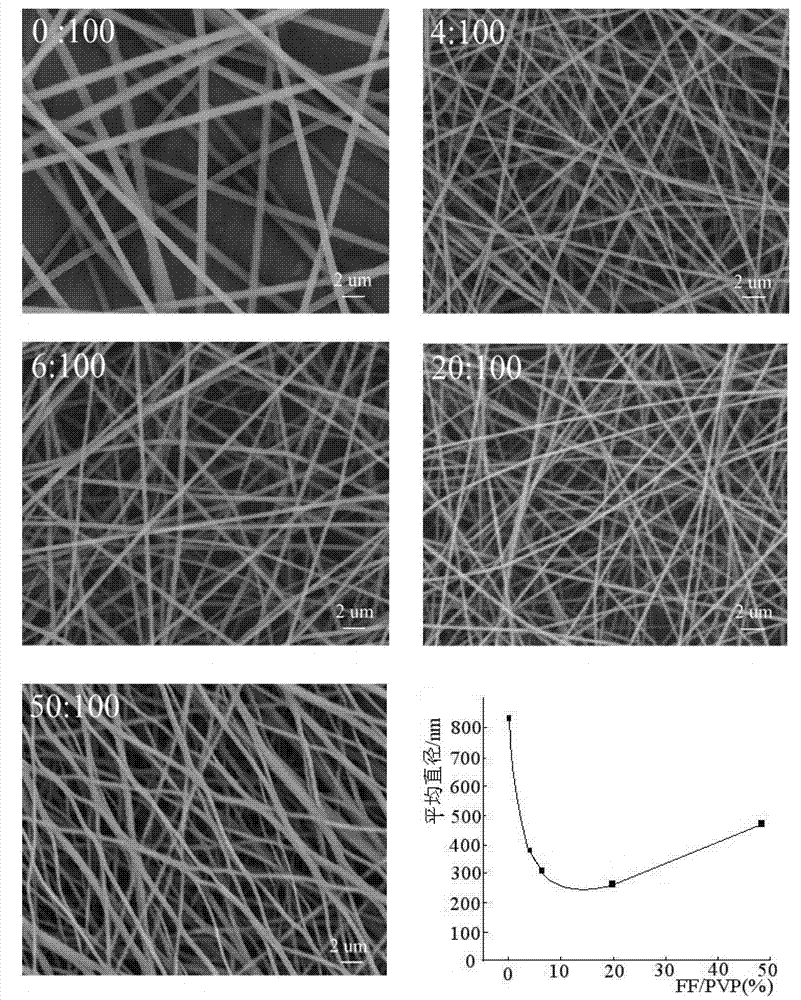

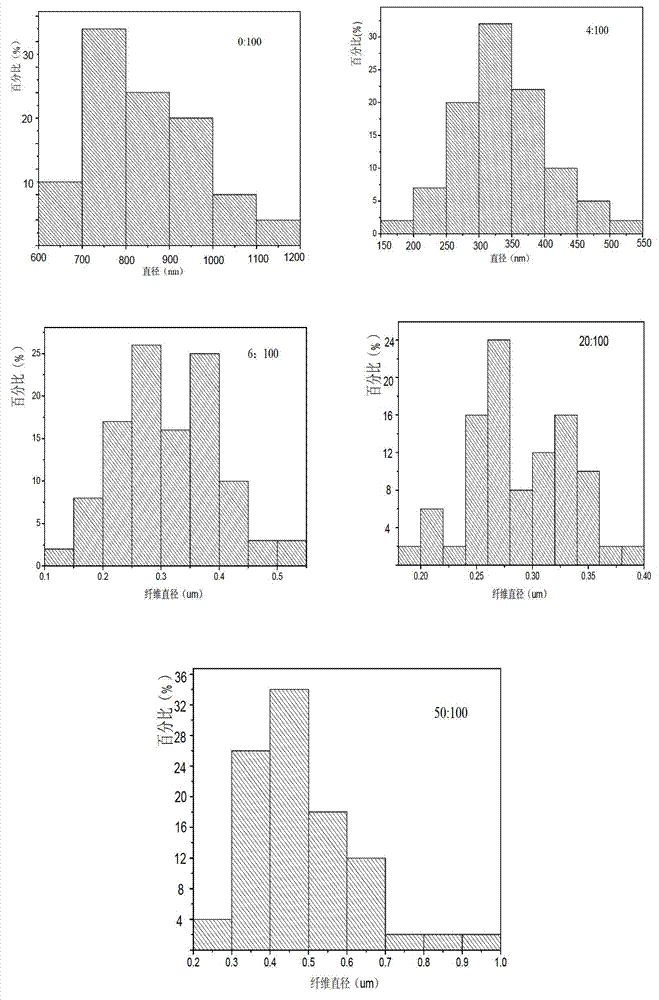

[0029] (2) Slowly add the weighed PVP and FF powder into the above-mentioned reaction vessel under stirring condition, and continue to stir for 20-30 minutes until completely swollen; wherein, the content of PVP in the mixture of methanol and DMAc is fixed at 10% (w / w), the mass ratio of FF to PVP is: 0:100, 4:100, 6:100, 20:100, 50:100;

[0030] (3) Place the Erlenmeyer flask in a shaker, shake it at 25±2°C for 15-24 hours until it is completely dissolved, the polymer solution is transparent, and degas it by ultrasonic treatment for 15 minutes to obtain a spinning solution;

[0031] (4) Draw out the FF / PVP spinning solution with a 5ml syringe (the inner diameter of the needle is 0.4~0.7mm), fix it on the electrospinning device, fix the static voltage at 16kv, receive the distance at 25cm, and spray the flow rate at 1mL / h, and carry out Electrospinni...

Embodiment 2

[0037] (1) Put the mixture of methanol and N,N-methylacetamide (DMAc) at a volume ratio of 85:15 into the reaction vessel;

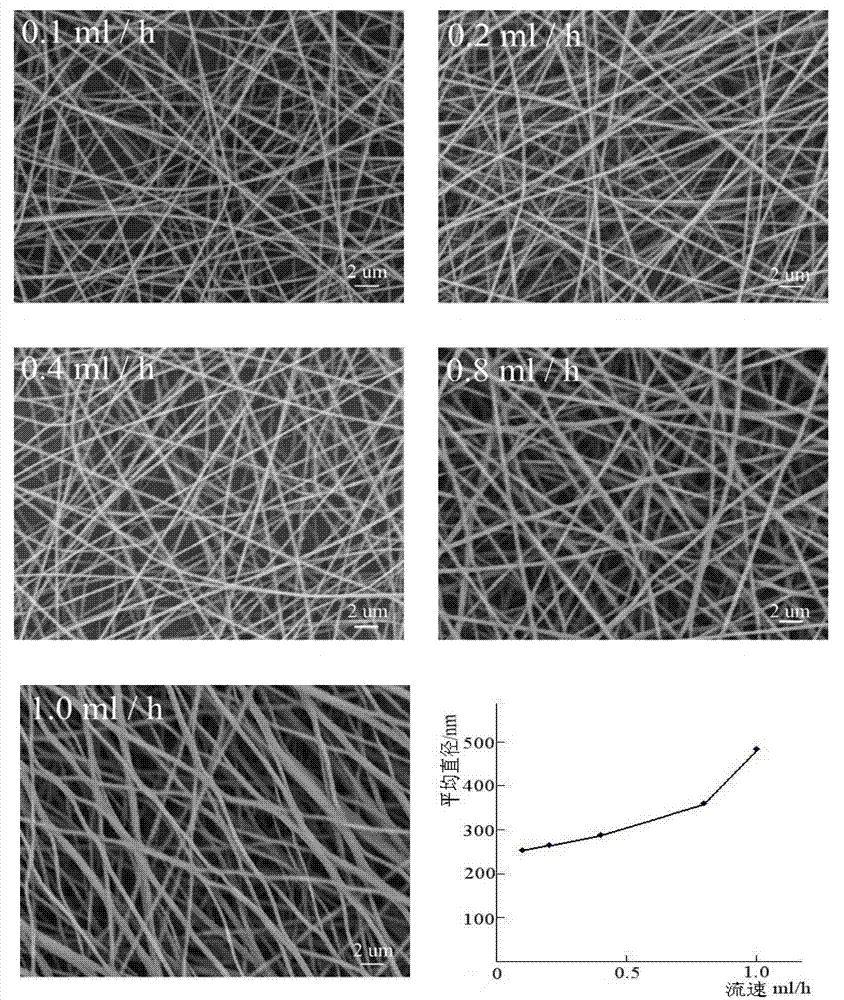

[0038] (2) Slowly add the weighed PVP and FF powder into the above-mentioned reaction vessel under stirring condition, and continue to stir for 20-30 minutes until completely swollen; wherein, the content of PVP in the mixture of methanol and DMAc is fixed at 10% (w / w), the mass ratio of FF to PVP is 50:100;

[0039] (3) Place the Erlenmeyer flask in a shaker, shake it at 25±2°C for 15-24 hours until it is completely dissolved, the polymer solution is transparent, and degas it by ultrasonic treatment for 15 minutes to obtain a spinning solution;

[0040] (4) Use a 5ml syringe (the inner diameter of the needle is 0.4~0.7mm) to extract the FF / PVP spinning solution, fix it on the electrospinning device, fix the static voltage at 16kv, receive the distance at 25cm, and spray the flow rate at 0.1mL / h , 0.2mL / h, 0.4mL / h, 0.8mL / h, 1.0mL / h, electrospun to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com