Insulating composite wall body of building

A composite wall and building thermal insulation technology, which is applied in thermal insulation, construction, building components, etc., can solve the problems of inconvenient connection of concrete-supported cantilever beams, inconvenient construction, poor fire prevention of curtain wall decoration, etc., and increase energy-saving and thermal insulation effects , Convenience in construction, beneficial to the anti-seismic effect of buildings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

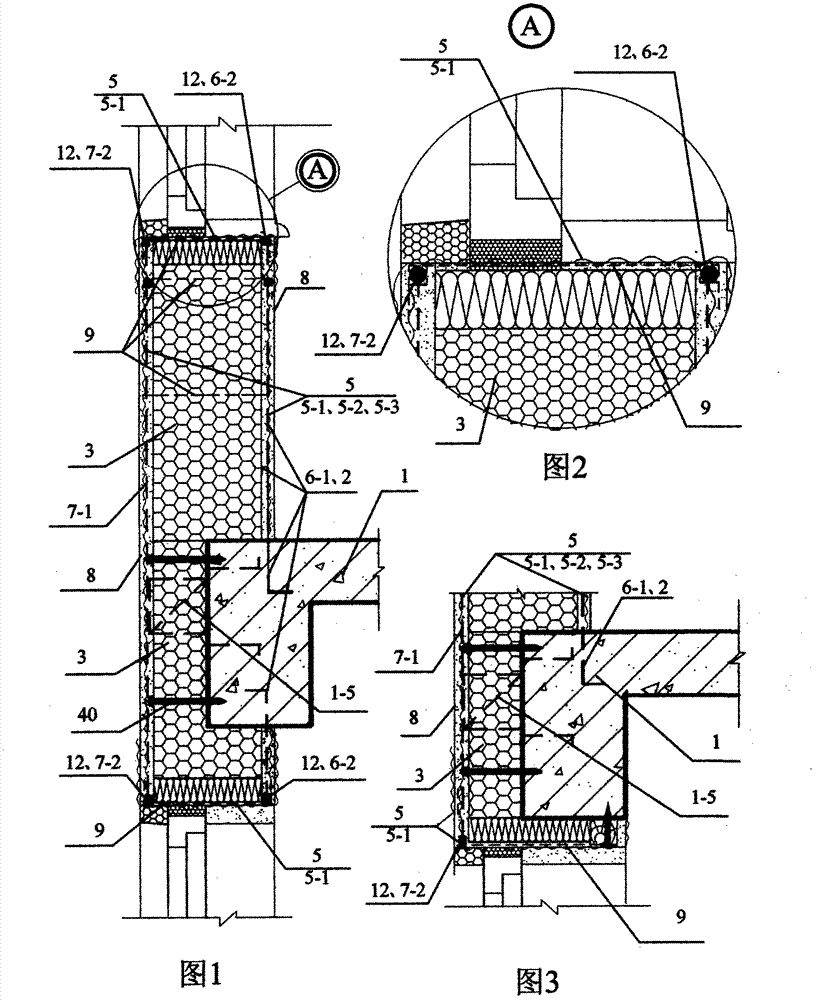

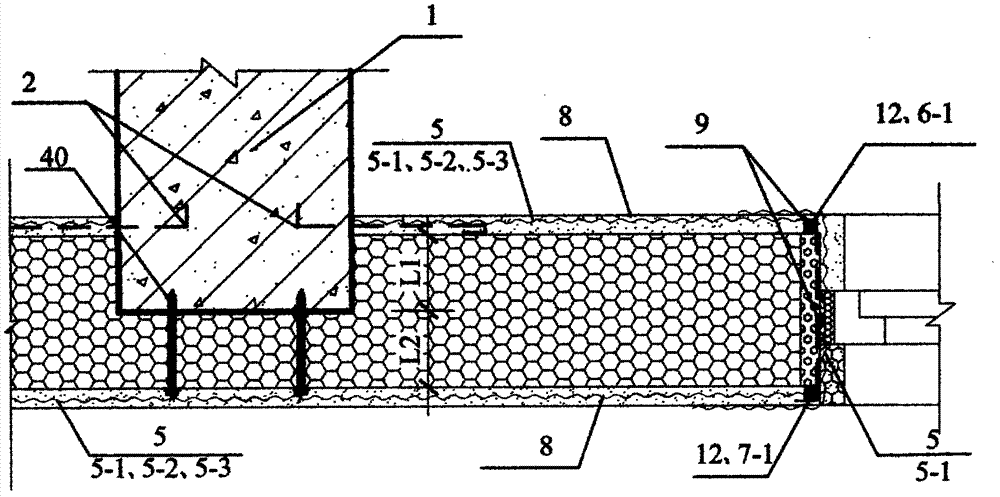

[0072] Embodiment one: see Figure 1 ~ Figure 3 , Figure 6 , Figure 10 , Figure 11 , a building thermal insulation composite wall in this embodiment is composed of a main building structure 1, cantilevered steel trusses 1-5, a core layer 3, a mesh tensile material 5, and a protective layer 8; the main building structure 1 is concrete frame structure, steel structure, wood structure and masonry columns; the core layer 3 is polymer thermal insulation material, plant straw, paper honeycomb board, thermal insulation mortar board, and the inside and outside of the core layer 3 can be Two kinds of materials, the core layer 3 in the different positions can also be different materials; the mesh tensile material 5 is a metal mesh 5-2 or an alkali-resistant mesh cloth 5-1 or a bamboo reinforcement mesh 5-3; The protective layer 8 is a plastering layer of cement mortar or fine stone concrete, or a modified cement mortar or a modified fine stone concrete plastering layer; truss, or ...

Embodiment 2

[0076] Embodiment two: see Figure 1 ~ Figure 3 , Figure 6 , Figure 12 , Figure 13 The difference between this embodiment and Embodiment 1 is that the present embodiment increases door and window reinforcing steel bars 12; section settings, see Figure 12 , or door and window reinforcing bars 12 are set along the periphery of the door and window, see Figure 13 ; The mesh tensile material 5 connects the reinforcement bars 12 of the indoor and outdoor doors and windows to each other.

[0077] The weakest part of the body of wall is exactly the hole corner position, arranging door and window reinforced steel bars 12 helps to avoid hole cracking. The Φ4 galvanized steel bar can be used as the reinforced steel bar for doors and windows, which is easy to install and has good durability. Figure 13 It is most convenient to install along the perimeter of the door and window.

[0078] Embodiments 1 and 2 use cantilevered steel trusses to hang the outdoor net-like tensile mat...

Embodiment 3

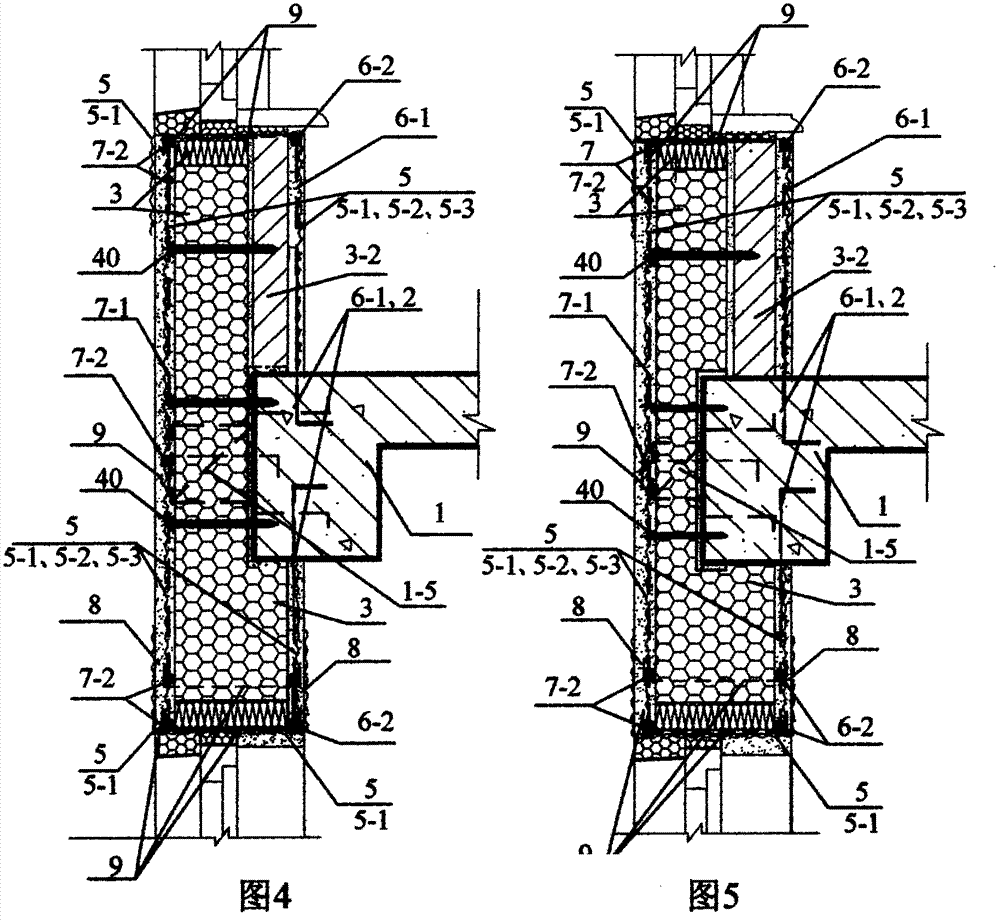

[0084] Embodiment three: see Figure 1 to Figure 6 , Figure 10 , Figure 11 , Figure 14 , Figure 16 , the difference between this embodiment and Embodiment 1 is: this embodiment adds outdoor steel bars 7, indoor steel bars 6, and internal and external pull wires 9; the core layer 3 can also be mineral wool, lightweight masonry, or the core There is also a masonry wall 3-2 on the indoor side of the layer 3, and the core layer 3 is connected with the masonry wall 3-2 to become a core layer 3 compounded with the masonry wall 3-2; the outdoor reinforcement 7 includes an outdoor Vertical steel bars 7-1, outdoor horizontal steel bars 7-2; the indoor steel bars 6 include indoor vertical steel bars 6-1, indoor horizontal steel bars 6-2; the outdoor vertical steel bars 7-1 and the cantilevered steel truss 1- 5 connection, or the outdoor vertical reinforcement 7-1 is connected to the main structure of the building 1, see Figure 16 ; The outdoor horizontal steel bar 7-2 has one o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com