Production method for high-viscosity high-purity carboxymethylcellulose by using bamboo pulp as raw material

A technology of carboxymethyl cellulose and production method, which is applied in the field of producing high-viscosity and high-purity carboxymethyl cellulose, can solve problems such as complicated procedures, high viscosity, and environmental pollution, and achieve rich sources, low production costs, and low production costs. Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

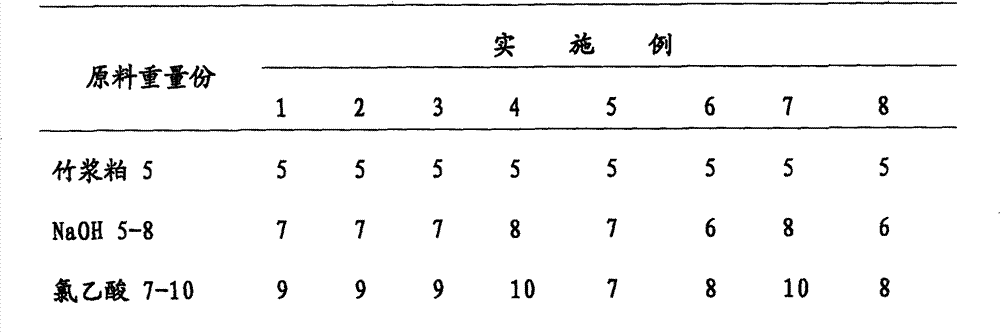

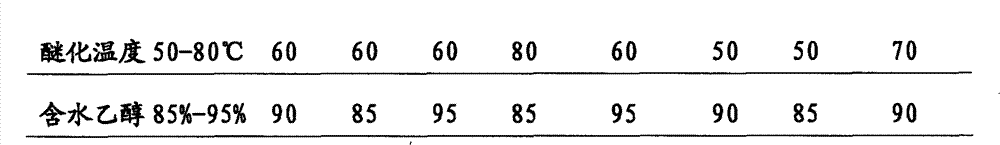

Examples

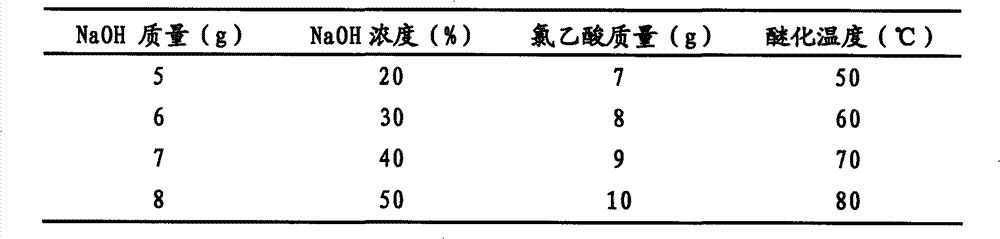

Embodiment 1

[0019] Embodiment 1 (seeing the corresponding raw materials and parts by weight of Embodiment 1 in the table): add 5 parts by weight of bamboo pulp powder (the same below) in the reactor, add 100 parts of volume ratios and be 90% aqueous ethanol, stir 10-20 Minutes, add 7 parts of NaOH, prepare NaOH into an aqueous solution with a mass ratio concentration of 30%, stir at normal pressure and 20-30°C for 1 hour to generate alkalized cellulose, then add 9 parts of chloroacetic acid, and control the reaction temperature at 60°C , etherification reaction for 2 hours, cooled to room temperature, neutralized to neutral with 80% acetic acid aqueous solution by volume, and suction filtered to obtain a yellow etherified product, which was washed by conventional washing and pressure filtration with a volume ratio of 80% Wash 4 times with ethanol, then wash 1 time with 95% ethanol, dry and pulverize to obtain white fibrous powder, which is the high-viscosity and high-purity carboxymethyl c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com