Device for regenerating waste and old thermosetting plastics, and technology thereof

A recycling equipment and thermosetting technology, applied in the field of waste thermosetting plastic recycling equipment and recycling process, can solve the problems of poor applicability, poor product performance and high production cost, achieve orderly and compact settings, restore processability, and restore plasticity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

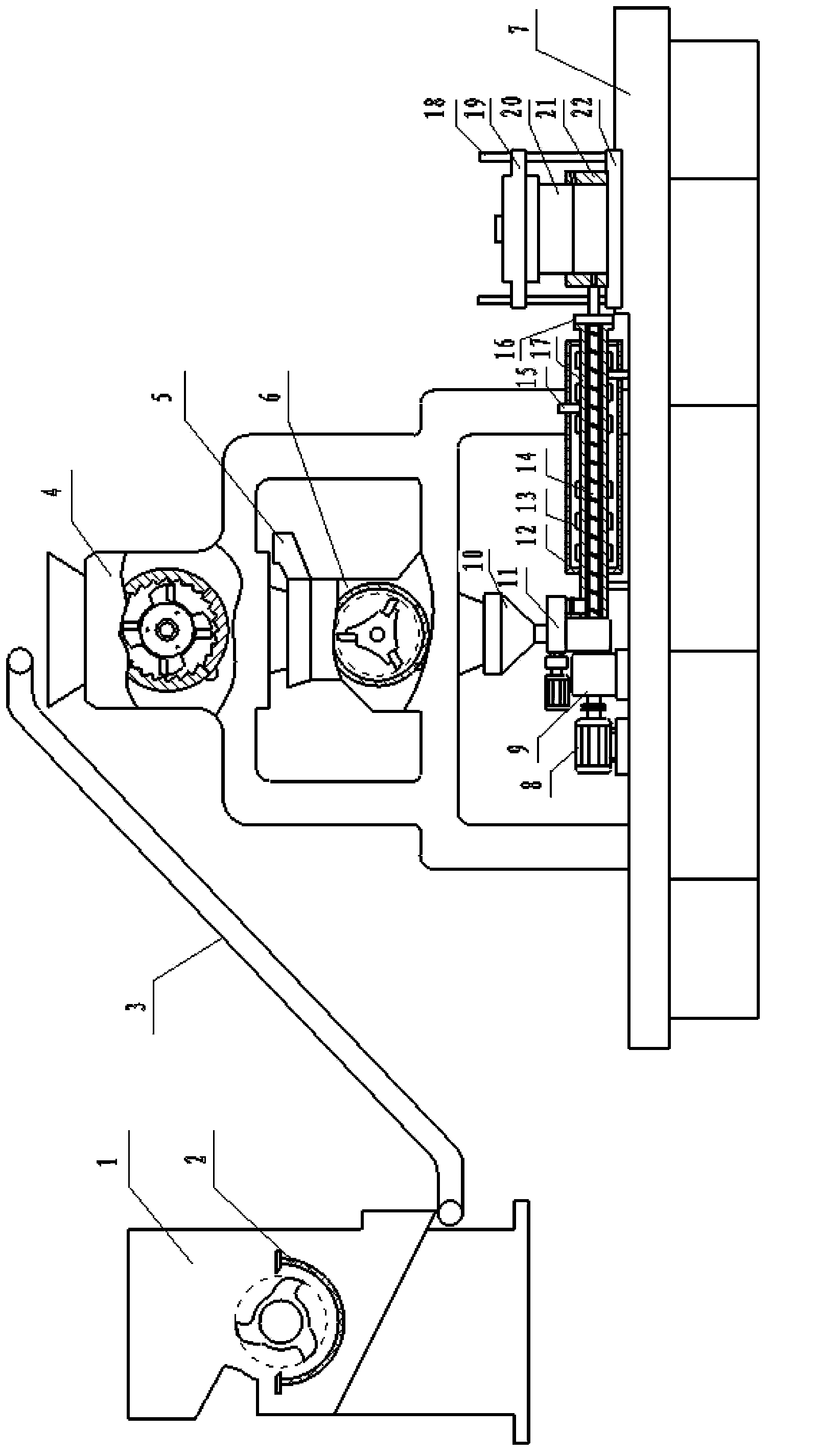

[0051] This embodiment takes waste thermosetting phenolic laminated plastics as an example:

[0052] Firstly, the waste thermosetting phenolic laminated plastics are coarsely crushed through the crushing device 1, and the coarsely crushed materials fall through the screen 2 to obtain crushed materials, which are then transported to the feed port of the degradation device 4 by the conveyor belt 3.

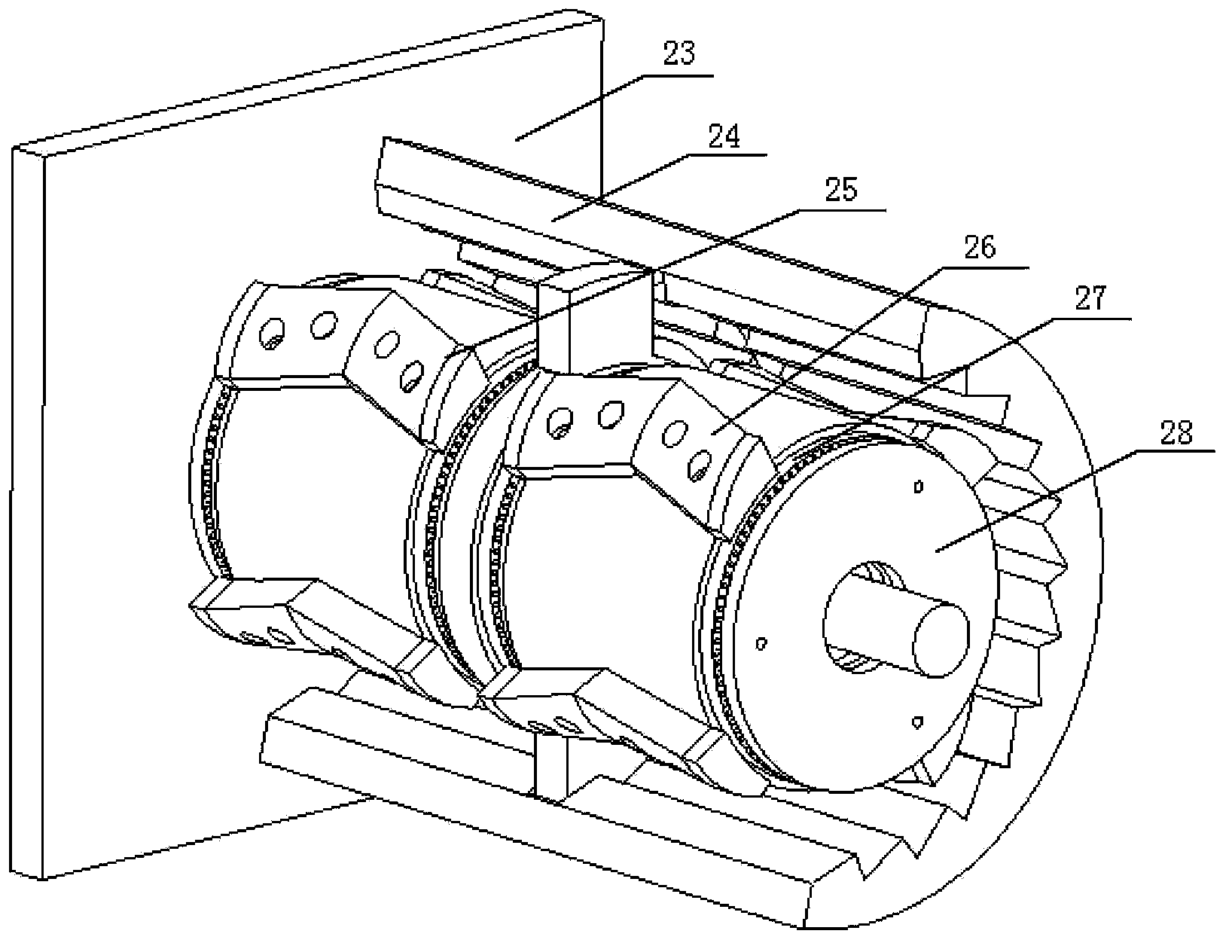

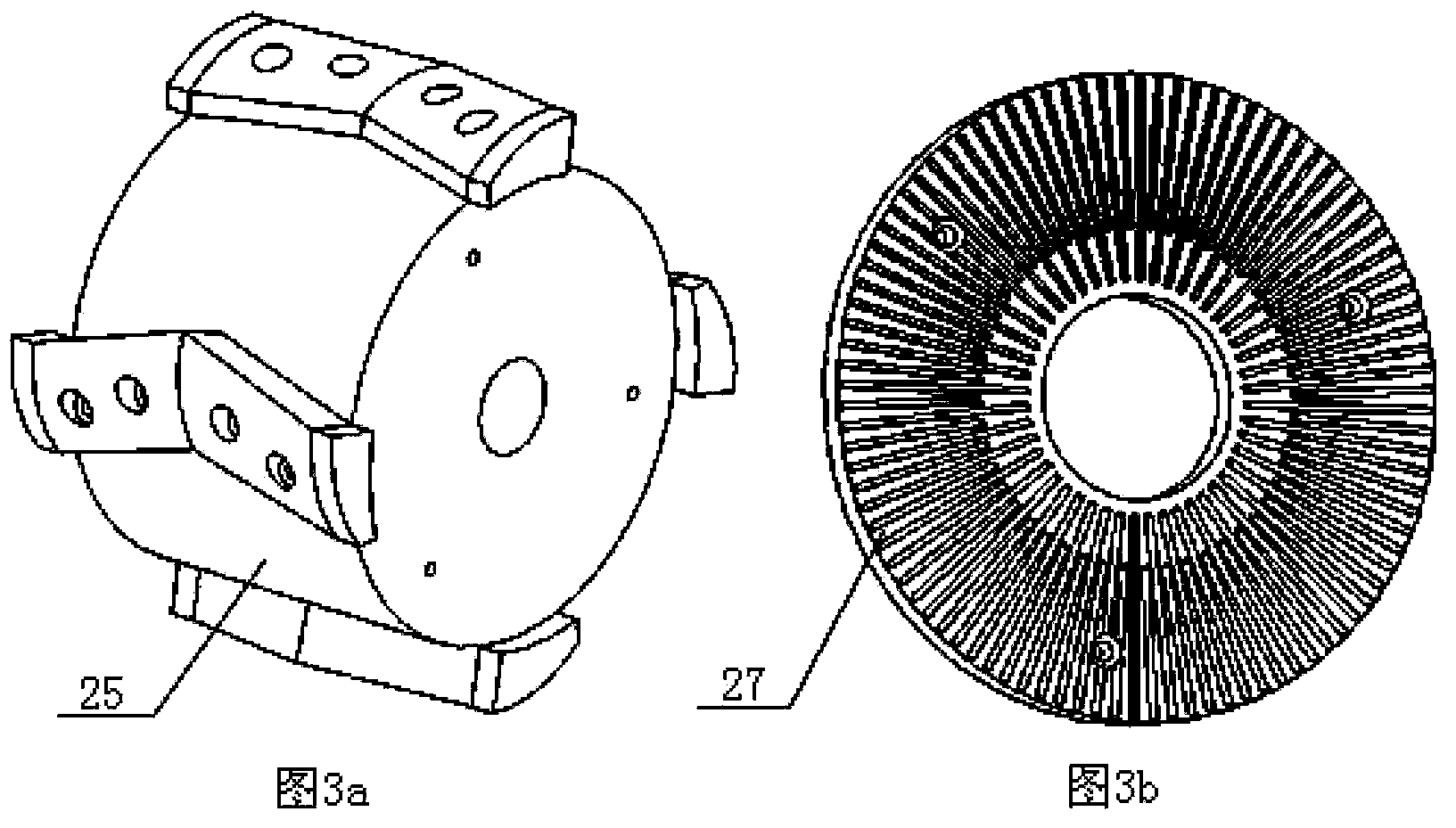

[0053] The crushed material enters the degradation device 4 from the feed port, and the rotating speed of the shearing knife shaft is controlled to be 3500r / min. The relatively coarse material starts to be sheared through the relative rotation between the shearing knife shaft and the annular fixed knife 24, and then follows The fine materials rotating along the shearing knife shaft enter into the grinding chamber between the movable grinding disc and the static grinding disc, and the relative rotation between the movable grinding disc 27 and the static grinding disc 28 makes the mate...

Embodiment 2

[0059] This embodiment takes waste and old thermosetting rigid polyurethane plastics as an example:

[0060] The entire regeneration process flow is the same as in Example 1. During the degradation process, the rotational speed of the shearing knife shaft is set at 2500 r / min, and the degradation time is 80 minutes. In the regeneration process, the ingredients and degradation materials added are: 80% degradation materials, 19% polypropylene PP, 0.5% antioxidant 1010 and 0.5% antioxidant 168, and the rotation speed of the regeneration device 6 is set according to the mass percentage. 1000r / min, complete regeneration time is 12 minutes. During the extrusion compression process, the temperature of the barrel 17 is controlled at 170-180° C., the size of the pressure press is 7 Mpa, the size of the holding pressure is 4 Mpa, and the holding time is 9 minutes.

[0061] The pressed thermosetting rigid polyurethane plastic parts have been tested for mechanical properties, and have a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com