Preparation method and using method of water curing putty product

A water-curing and putty technology, applied in the direction of filling slurry, etc., can solve the problems of unhealthy, perishable, and safety hazards of operators, and achieve the effect of highlighting environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

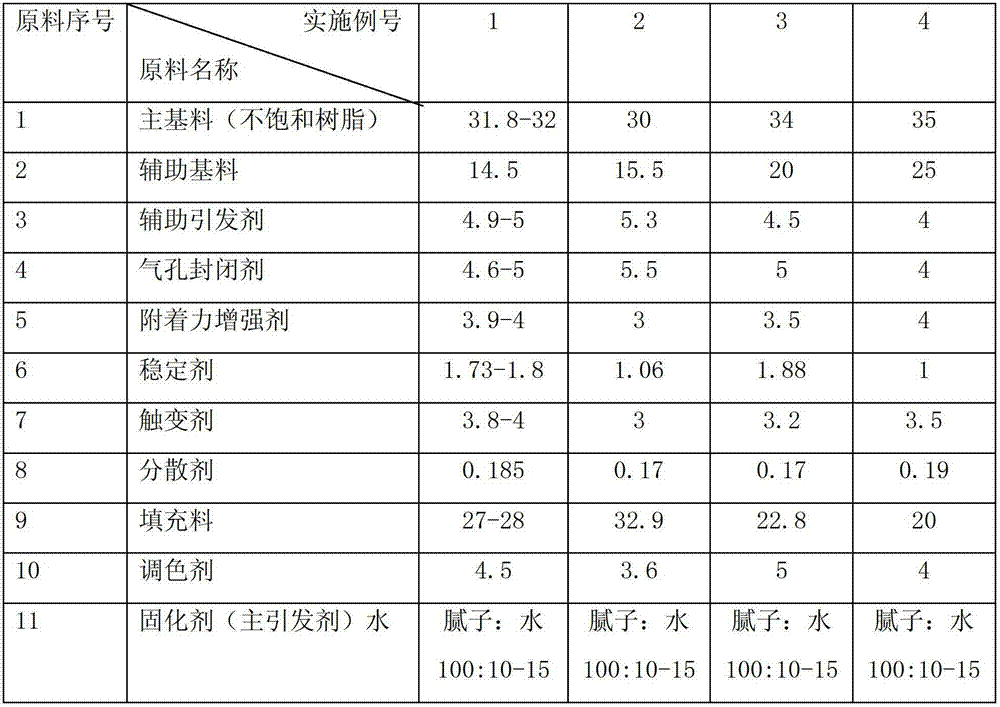

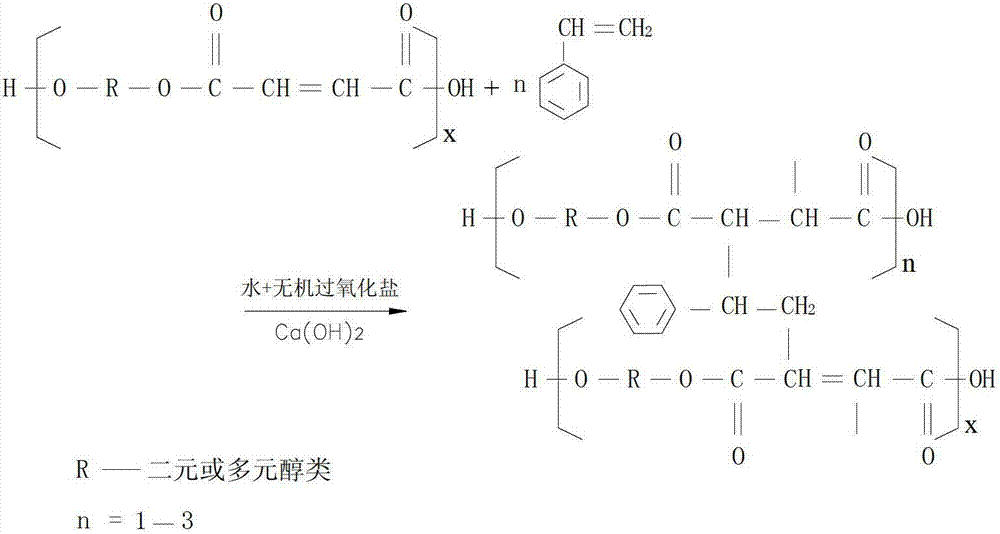

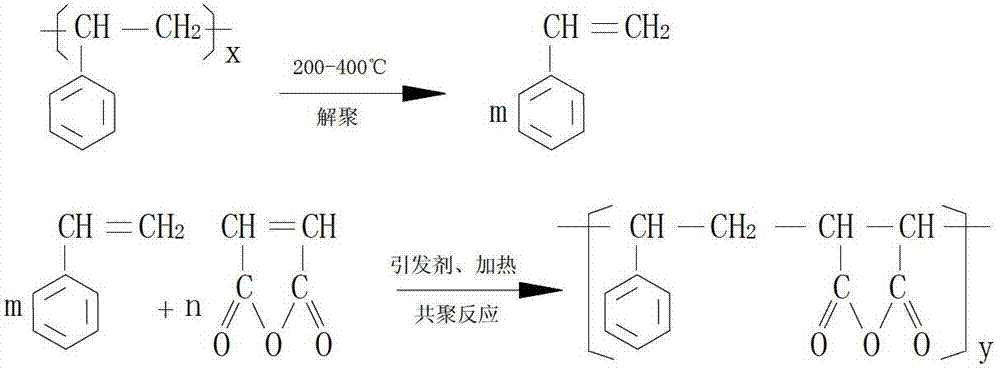

[0007] A method for preparing and using a water-cured putty product, characterized in that: the preparation method of the putty product comprises the following steps: taking 30-35 parts by weight of an unsaturated resin modified with dicyclopentadiene as the main base material, The water-cooled slag from the ironmaking process of steel mills and ferroalloy plants is calcined at 1300-1400°C in a muffle furnace, cooled and ground to 300-400 mesh, and then 3-5wt.% calcium sulfate hemihydrate is added to form a total of 14.5 ——25 parts by weight of auxiliary base material, after the main base material and auxiliary base material are put into a 1500-1800L / min high-speed disperser and fully dispersed, gradually add 4-5.3 parts by weight of auxiliary initiator, air hole Sealing agent 4——5.5 parts by weight, adhesion enhancer 3-4 parts by weight, stabilizer 1-1.88 parts by weight, thixotropic agent 3-4 parts by weight, dispersant 0.17-0.19 parts by weight, filler 20-32.9 parts by weigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com