Vacuum coating device, vacuum coating control system and control method

A vacuum coating and control system technology, applied in vacuum evaporation coating, sputtering coating, ion implantation coating, etc., can solve problems such as uneven evaporation temperature of oxide materials, uniformity affected by adding gas, failure of cryopump, etc. , to improve quality and work efficiency, prevent crucible damage or substrate scrapping, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

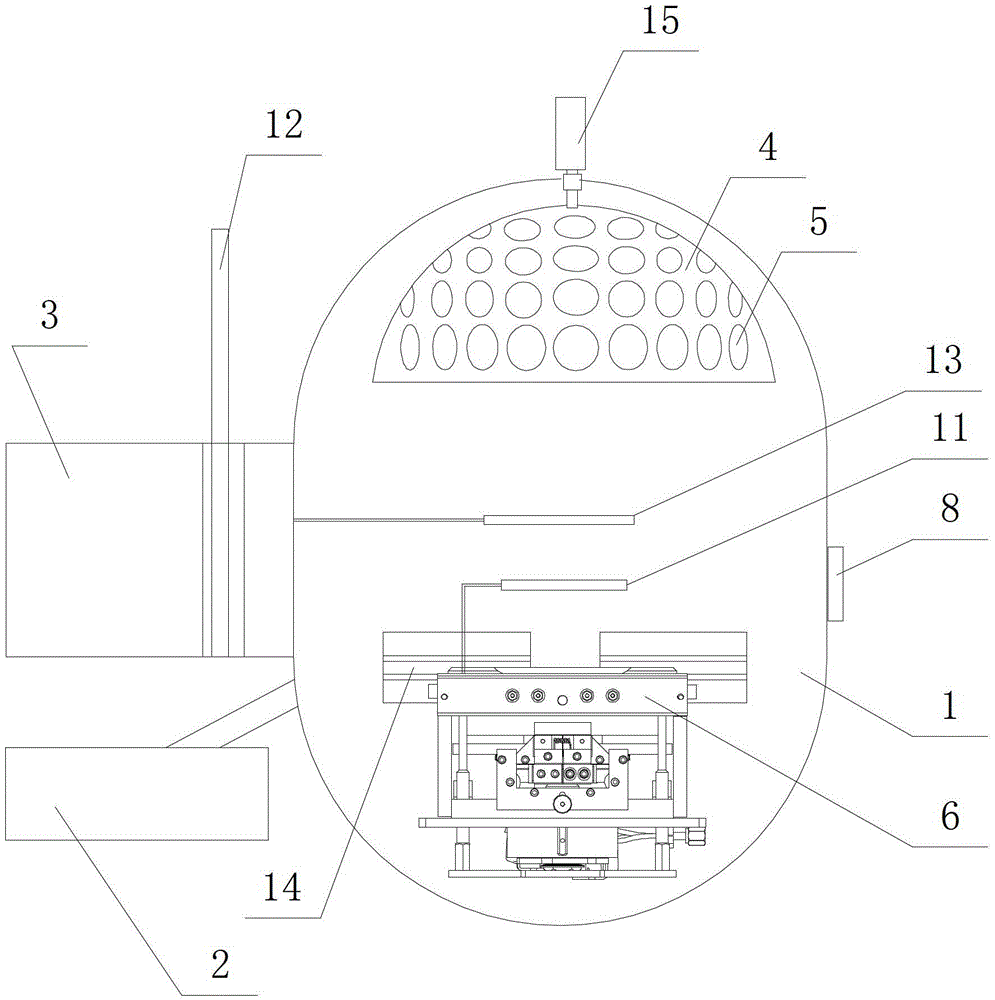

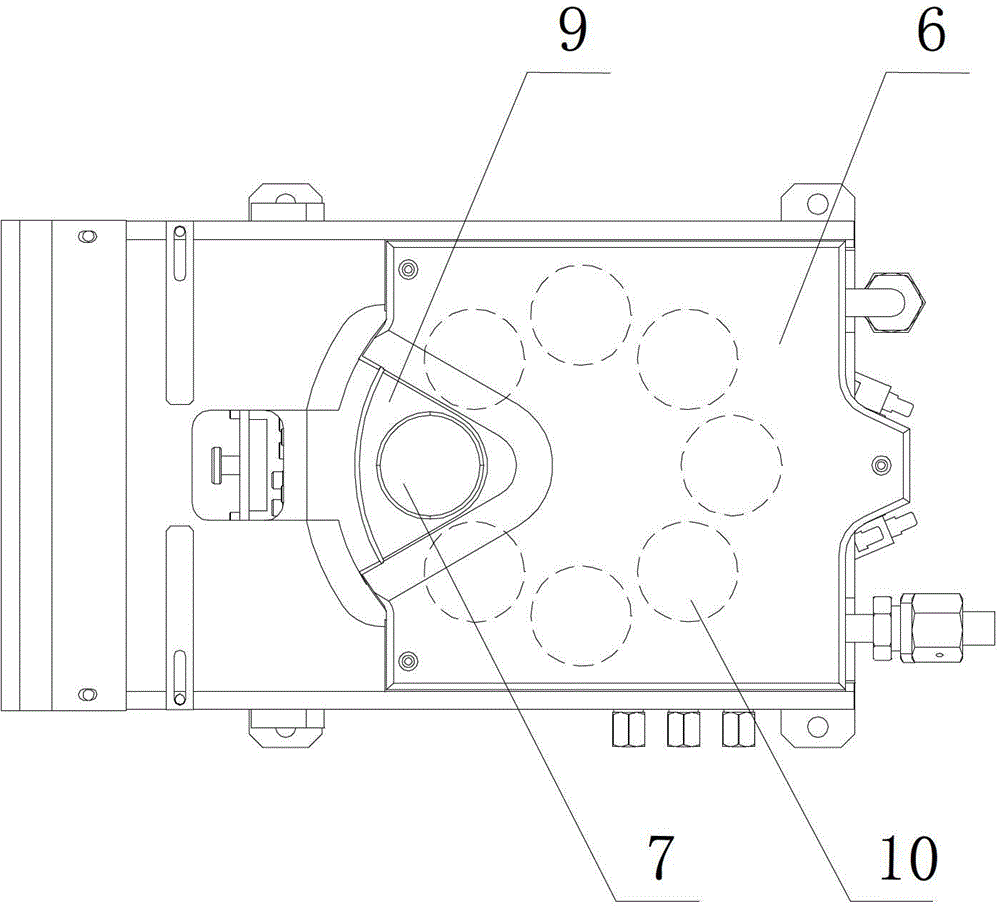

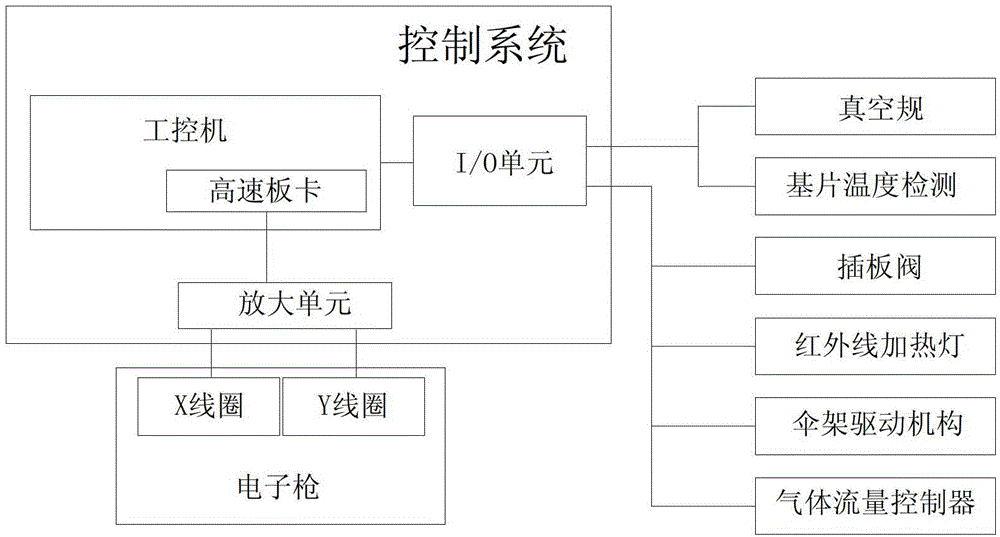

[0046] Embodiment: a kind of vacuum coating device of the present embodiment, such as figure 1 and figure 2 As shown, it includes a vacuum chamber 1, a vacuum pump 2 connected to the vacuum chamber, and a cryopump 3. A plug valve 12 is designed on the connecting pipe between the cryopump and the vacuum chamber, and an umbrella stand driving mechanism is designed on the top of the vacuum chamber. 15 and the umbrella stand 4, the umbrella stand driving mechanism is connected with the umbrella stand, the substrate 5 to be coated is placed on the umbrella stand, and the e-type electron gun 6 is designed at the bottom of the vacuum cavity, and the electron gun is designed to be arranged in a circle and can be arranged along the The crucible position where the center of the circle rotates, a crucible 7 is placed on the crucible position, and the crucible position includes a heating position 9 and several storage positions 10, coating materials are placed in the crucible, and an obs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com