Schottky diode and method of formation of Schottky diode

A technology of Schottky diodes and Schottky metals, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., and can solve the problem of narrowing the conduction area, increasing conduction loss, and increasing forward conduction resistance, etc. problems, to achieve the effect of increasing breakdown voltage and increasing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

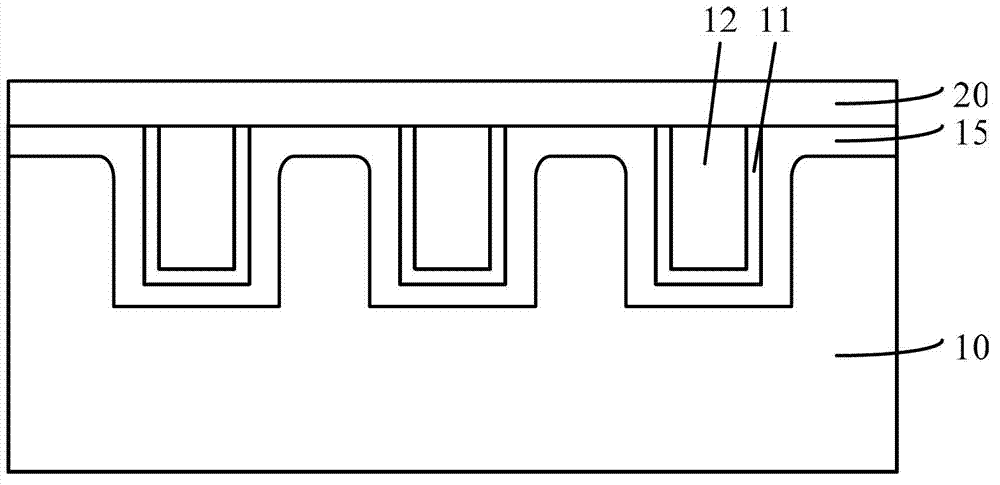

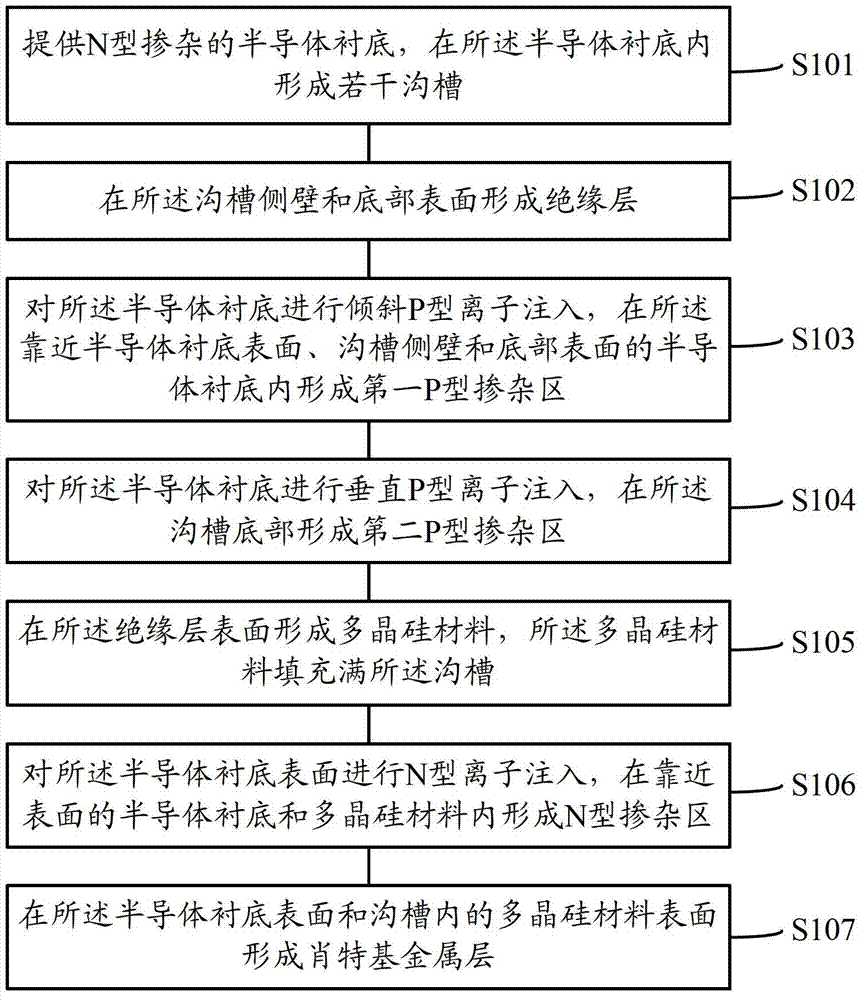

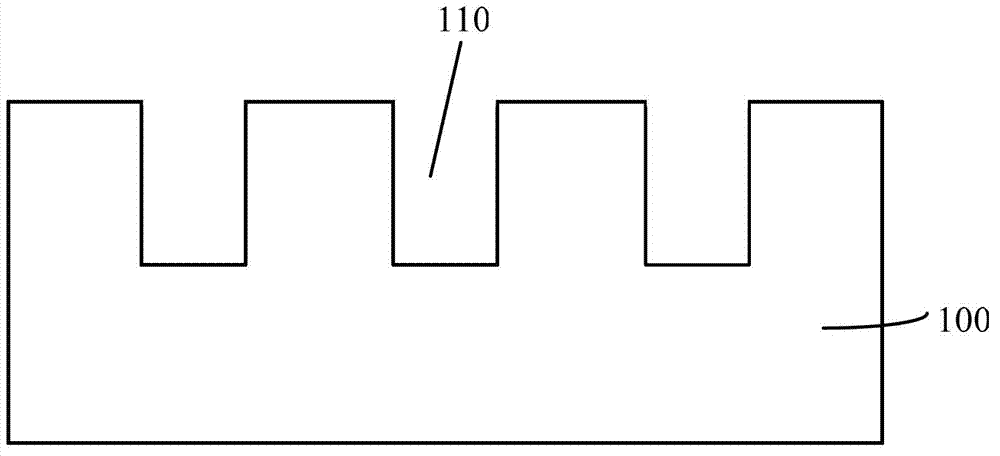

[0033] Since the required distance between adjacent trenches of existing trench Schottky diodes is small, when the distance between the two trenches is small, the conduction from the metal layer to the semiconductor substrate The conduction area becomes narrower, the forward conduction resistance becomes larger, the conduction loss and switching loss become larger, and the forward voltage drop becomes higher. For this reason, the inventor has proposed a Schottky diode and its formation method after research. P-type doped region. When a reverse bias is applied to the Schottky diode subsequently, that is, a positive voltage is applied to the semiconductor substrate, and a negative voltage is applied to the Schottky metal layer, due to the reverse bias, the trench sidewall The thickness of the depletion region between the P-type doped region and the semiconductor substrate is easy to become larger, and the two depletion regions close to the sidewalls of the trench are easy to pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com