Preparation method of frozen yoghourt

A technology for freezing yogurt and yogurt, which is applied in the directions of milk preparations, dairy products, applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

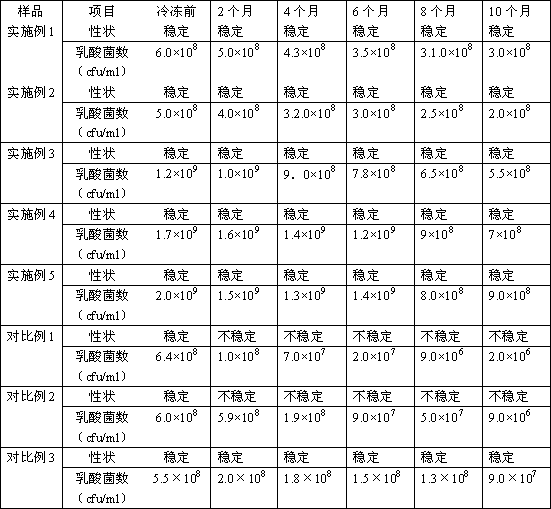

Examples

Embodiment 1

[0040] 1) Milk preparation

[0041] Weigh raw materials according to the above weight ratio:

[0042] 20% skimmed milk powder, 4% sucrose, 0.05% trehalose, 0.2% sodium glutamate, 0.6% pectin, 0.2% essence, and the rest of water, add the above substances into water with a water temperature of 60°C, dissolve and prepare milk ;

[0043] 2) homogeneous

[0044] The milk is homogenized at 25MPa;

[0045] 3) Sterilization

[0046] Sterilize the homogenized milk at 92°C for 5 min;

[0047] 4) cooling

[0048] Cool the sterilized milk to 37°C;

[0049] 5) Inject Lactobacillus casei (Lactobacillus casei) accounting for 0.001% of the total weight of the milk into the milk treated in step 4), and ferment at 37°C for 72 hours to form yogurt;

[0050] 6) Fill the yogurt obtained in step 5);

[0051] 7) The yogurt that has been processed in step 6) is cooled to 4°C first, and then stored below -15°C.

Embodiment 2

[0053] 1) Milk preparation

[0054] Weigh raw materials according to the above weight ratio:

[0055] Skimmed milk powder 8%, sucrose 12%, trehalose 4%, sodium glutamate 0.2%, propylene glycol alginate 0.1%, essence 0.01%, water balance, add the above substances into water with a water temperature of 45°C, dissolve and prepare milk liquid;

[0056] 2) homogeneous

[0057] The milk is homogenized at 15MPa;

[0058] 3) Sterilization

[0059] Sterilize the homogenized milk at 88°C for 5 min;

[0060] 4) cooling

[0061] Cool the sterilized milk to 44°C;

[0062] 5) Introduce 0.5% direct-injected lactic acid bacteria into the milk treated in step 4) and ferment at 44°C for 4 hours to form yogurt. The direct-introduced lactic acid bacteria are produced by Lactobacillus acidophilus acidophilus) and Lactobacillus delbrueckii subsp.bulgaricus were mixed according to the ratio of viable bacteria at 1:1;

[0063] 6) Fill the yogurt obtained in step 5);

[0064] 7) The yogurt th...

Embodiment 3

[0066] 1) Milk preparation

[0067] Weigh raw materials according to the above weight ratio:

[0068] 15% skimmed milk powder, 4% sucrose, 2% trehalose, 0.1% sodium glutamate, 0.3% sodium carboxymethylcellulose, 0.1% essence, and the rest of water. blended into milk;

[0069] 2) homogeneous

[0070] The milk is homogenized at 18MPa;

[0071] 3) Sterilization

[0072] Sterilize the homogenized milk at 92°C for 5 min;

[0073] 4) cooling

[0074] Cool the sterilized milk to 44°C;

[0075] 5) Inject Lactobacillus delbrueckii subsp.bulgaricus (Lactobacillus delbrueckii subsp.bulgaricus) accounting for 0.01% of the total weight of the milk into the milk treated in step 4), and ferment at 44°C for 8 hours to form yogurt;

[0076] 6) Fill the yogurt obtained in step 5);

[0077] 7) The yogurt that has been processed in step 6) is cooled to 4°C first, and then stored below -15°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com