Method for preparing platinum black/ platinum ruthenium black nano electro-catalyst by using sacrificial magnesia carrier

An electrocatalyst, magnesium oxide technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, chemical instrument and method, etc., can solve problems such as easy agglomeration and difficult preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

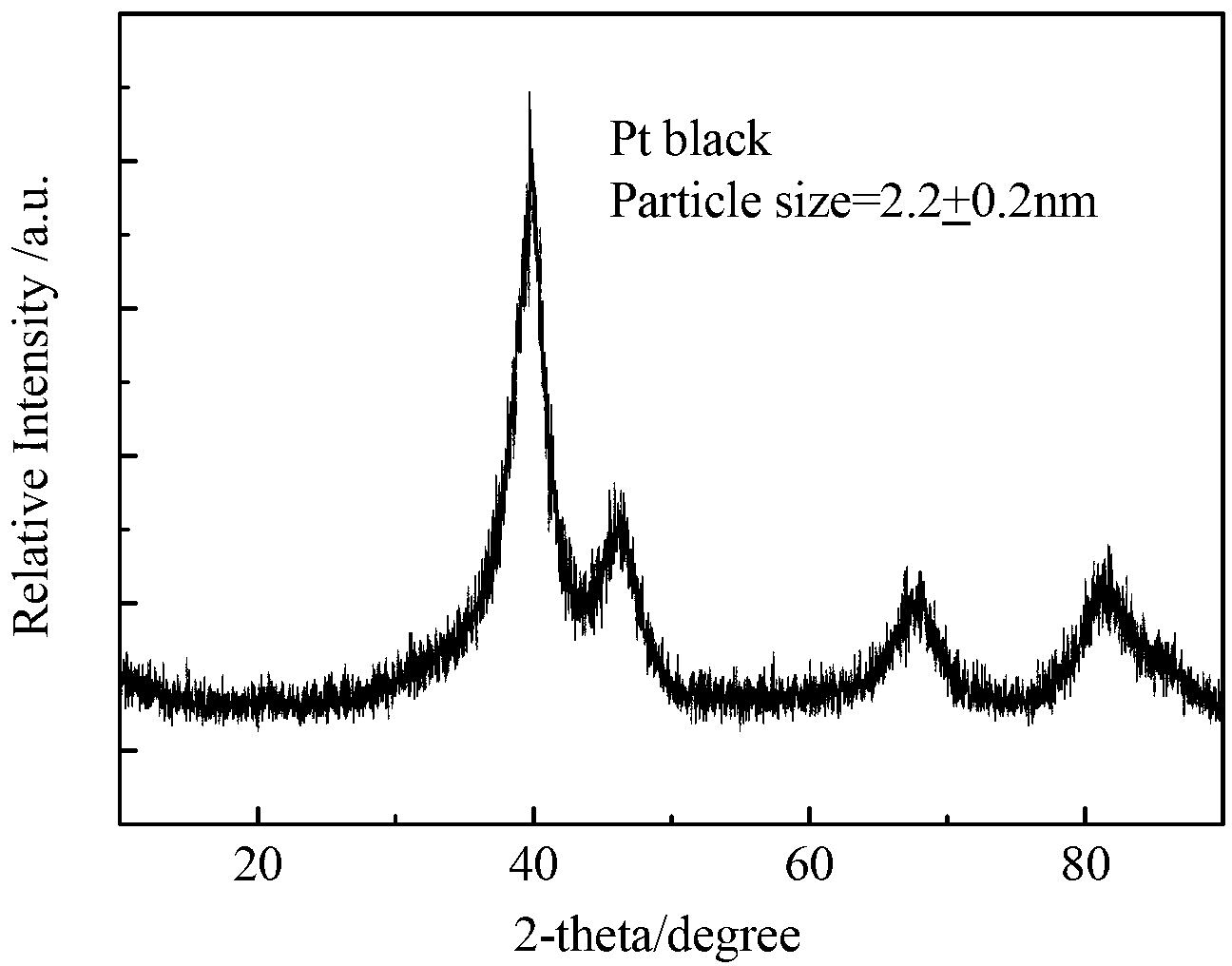

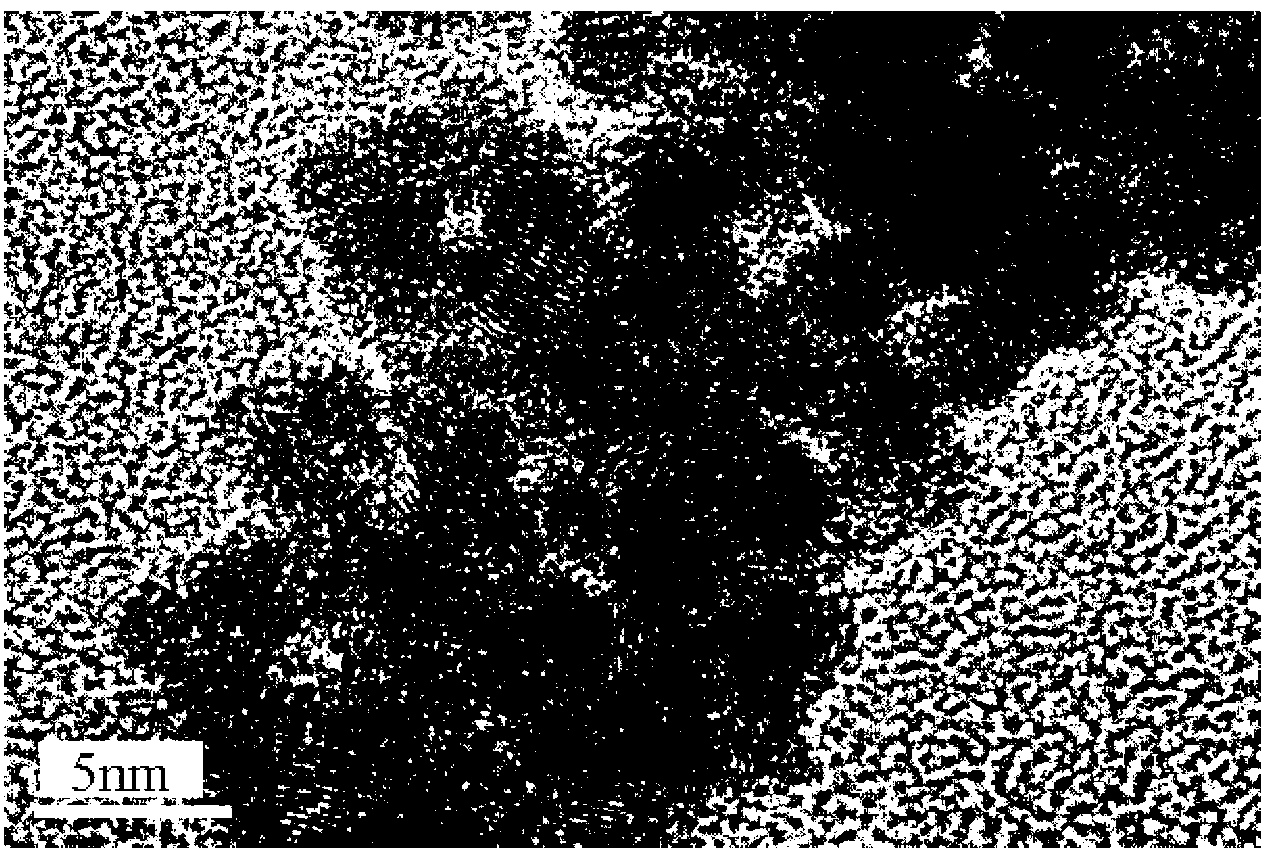

[0035] Embodiment 1: the preparation of platinum black nano electrocatalyst

[0036] 1. Weigh 3.2g of Na 2 PtCl 6 ·6H 2 O (31.3% metallic platinum content) and 3.4 g of CH 3 COONa was added into 150ml of methanol, and the pH value of the solution was controlled to be 7.5-8.5. First pass high-purity nitrogen gas for 15 minutes to remove the air in the solution, then react at 50°C in a carbon monoxide atmosphere for 20 minutes, and then react at room temperature and in a carbon monoxide atmosphere to obtain a blue-green metal carbonyl cluster solution (Component A).

[0037] 2. Add 4 g of magnesium oxide to the obtained component A under nitrogen protection, and stir at 55°C for 6 hours, then remove methanol (component B) in a nitrogen atmosphere at 70°C.

[0038] 3. Treat component (B) at 50°C for 6 hours in a mixed atmosphere of hydrogen and nitrogen (the volume ratio of hydrogen and nitrogen is 1:9), then wash with water and dry to obtain component (C).

[0039]4. Add 1...

Embodiment 2

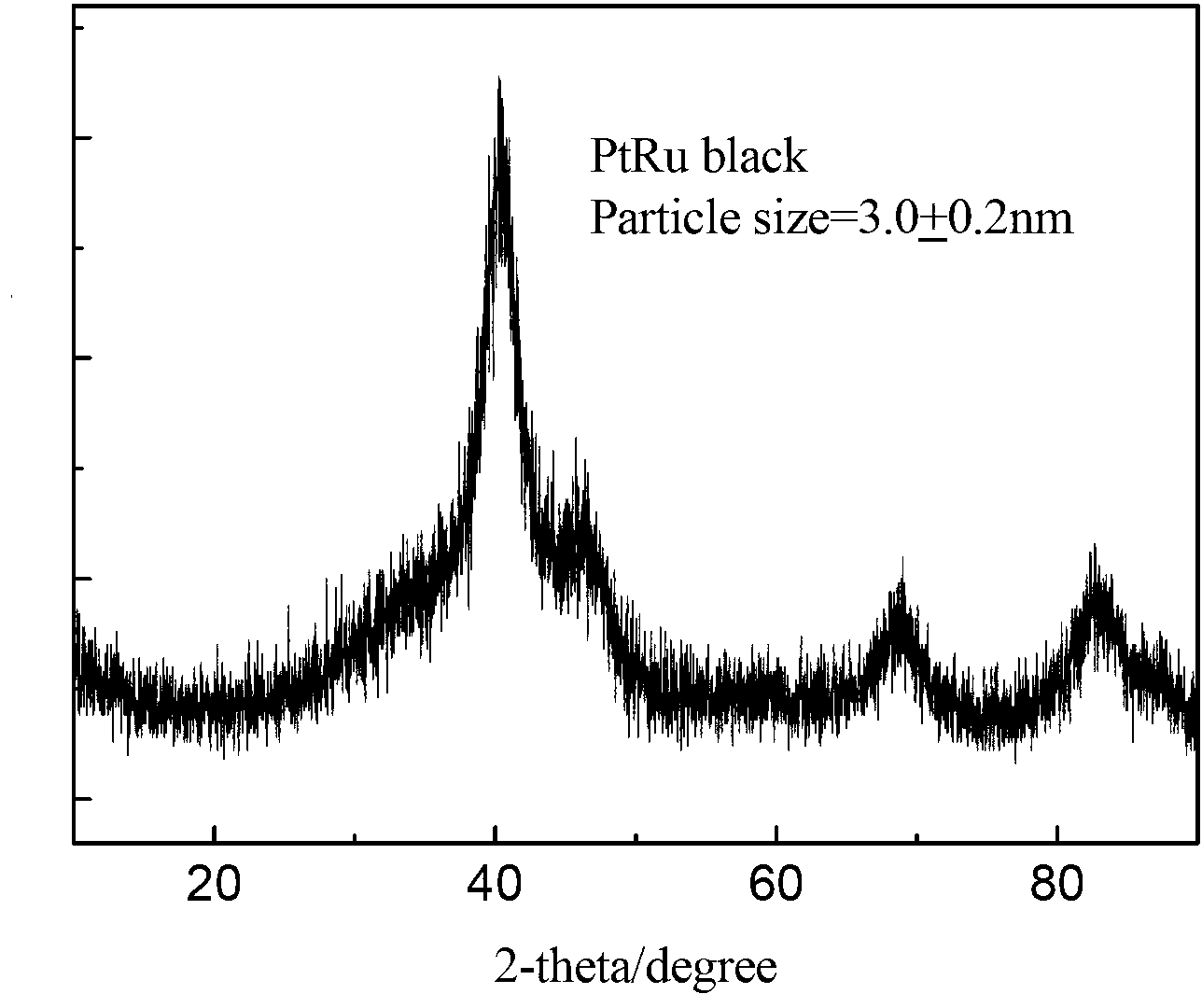

[0051] Embodiment 2: the preparation of platinum ruthenium black nano electrocatalyst

[0052] 1. Weigh 0.38g of Na 2 PtCl 6 ·6H 2 O (metallic platinum content 31.3%), 0.14g of RuCl 3 and 0.45 g of CH 3 COONa was added to 50ml of methanol, and the pH value of the solution was controlled to be 7.5-8.5. First pass high-purity nitrogen for 15 minutes to remove the air in the solution, then react at 50°C in a carbon monoxide atmosphere for 20 minutes, then react at room temperature and in a carbon monoxide atmosphere to obtain a blue-green metal carbonyl cluster solution ( Component F).

[0053] 2. Add 0.5 g of magnesium oxide to the obtained component F under the protection of nitrogen, and stir at 55°C for 6 hours, then remove the methanol (component G) in a nitrogen atmosphere at 70°C.

[0054] 3. Treat the component (G) at 200°C for 2 hours in a hydrogen / nitrogen mixed atmosphere (the volume ratio of hydrogen and nitrogen is 1:9), then wash with water and dry to obtain t...

Embodiment )

[0061] (1) Anode support layer: TGPH060, 20wt.% water proofing (from Toray company); anode microporous layer: Vulcan XC-72R (1mg cm -2 ) (from Cabot Company) and 20wt.%PTFE (from Dupont Company); anode catalyst layer (this embodiment): Pt-Ru / C (3.0mgcm -2 ) and Pt-Ru black (3.0mgcm -2 ) (LJY-2), 20wt.%Nafion (from Dupont);

[0062] or anode catalyst layer (existing technology): Pt-Ru / C (3.0mgcm -2 ) and Pt-Ru black (3.0mgcm -2 ) (JM), 20wt.%Nafion (from Dupont).

[0063] (2) Cathode supporting layer: TGPH060, 20wt.%; Cathode microporous layer: XC-72R (2mg·cm -2 ) and 25wt.%PTFE; cathode catalyst layer: Pt / C (3.0mg·cm -2 ) and Pt black (JM) (3.0mg cm -2 ), 15wt.%Nafion

[0064] (3) Nafion115 membrane (from Dupont).

[0065] The Pt-Ru / C and Pt-Ru black in the above-mentioned anode catalytic layer are all from Johnson Matthey Company (abbreviated as JM); the Pt / C in the above-mentioned cathode catalytic layer are all from Johnson Matthey Company (abbreviated as JM).

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com