Deep foundation pit soil-sintered porous brick and production method thereof

A production method and deep foundation pit technology, applied in the field of building wall materials, can solve the problems of complex raw material processing technology, long processing cycle, increased production energy consumption, etc., achieve good mechanical properties, protect cultivated land, and save land resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

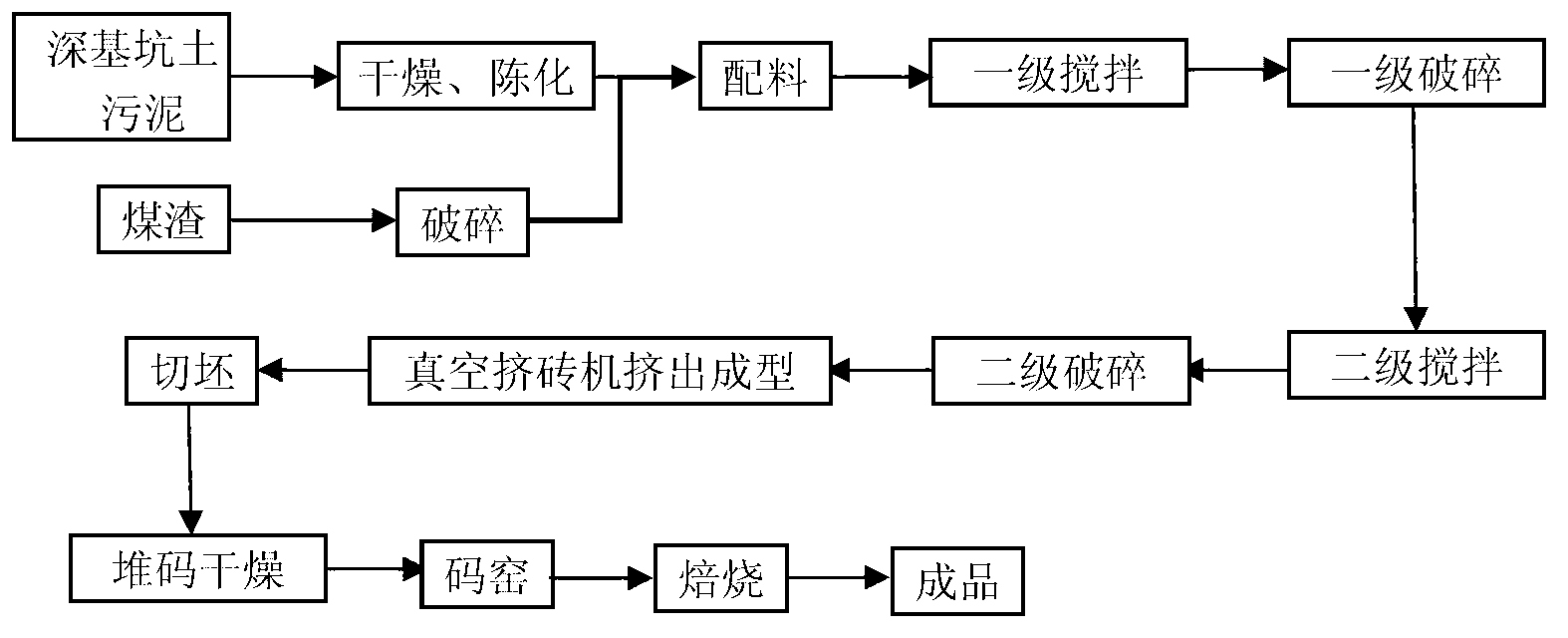

[0044] Deep foundation pit soil sintered porous brick is made of deep foundation pit soil, deep foundation pit soil dry powder, cinder, brick adobe regulator mixed, formed, dried and fired, deep foundation pit soil, deep foundation pit soil dry powder, cinder, brick adobe adjustment The mass ratio of the agent is 48%: 20%: 20%: 2%. The preparation process is as figure 1 As shown, the deep foundation pit soil pretreatment process: the deep foundation pit soil pretreatment process should include sorting, crushing, drying, aging and other treatment processes; specifically, after the deep foundation pit soil is excavated, use a stone picker to remove impurities After treatment, dry and age in the storage yard. The aging time is not less than 10 days, and the water content is 20-30% for later use; the deep foundation pit soil, dry powder of deep foundation pit soil, and cinder , Brick adjuster, after fully stirring and mixing, add an appropriate amount of water, the raw material m...

Embodiment 2

[0047] Deep foundation pit soil sintered porous brick is made of deep foundation pit soil, deep foundation pit soil dry powder, cinder, brick adobe regulator mixed, formed, dried and fired, deep foundation pit soil, deep foundation pit soil dry powder, cinder, brick adobe adjustment The mass ratio of the agent is 49%:20%:25%:6%. The preparation process is as figure 1 As shown, the deep foundation pit soil pretreatment process: the deep foundation pit soil pretreatment process should include sorting, crushing, drying, aging and other treatment processes; specifically, after the deep foundation pit soil is excavated, use a stone picker to remove impurities After treatment, dry and age in the storage yard. The aging time is not less than 10 days, and the water content is 20-30% for later use; the deep foundation pit soil, dry powder of deep foundation pit soil, and cinder , Brick adjuster, after fully stirring and mixing, add an appropriate amount of water, the raw material mixt...

Embodiment 3

[0050] Deep foundation pit soil sintered porous brick is made of deep foundation pit soil, deep foundation pit soil dry powder, cinder, brick adobe regulator mixed, formed, dried and fired, deep foundation pit soil, deep foundation pit soil dry powder, cinder, brick adobe adjustment The mass ratio of the agent is 40%:22%:30%:8%. The preparation process is as figure 1 As shown, the deep foundation pit soil pretreatment process: the deep foundation pit soil pretreatment process should include sorting, crushing, drying, aging and other treatment processes; specifically, after the deep foundation pit soil is excavated, use a stone picker to remove impurities After treatment, dry and age in the storage yard. The aging time is not less than 10 days, and the water content is 20-30% for later use; the deep foundation pit soil, dry powder of deep foundation pit soil, and cinder , Brick adjuster, after fully stirring and mixing, add an appropriate amount of water, the raw material mixt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com