Synthesis method for paranitrobenzoyl chloride

A technology of nitrobenzoyl chloride and p-nitrobenzoic acid, which is applied in the field of synthesis of p-nitrobenzoyl chloride, can solve the problem of not finding detailed literature on nitrobenzoyl chloride, and avoid the recovery of solvents and materials , high purity, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

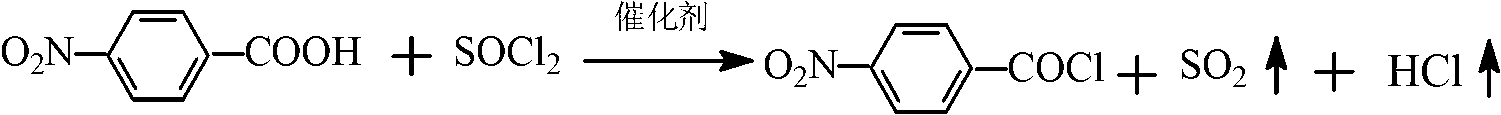

Method used

Image

Examples

Embodiment 1

[0024] Add 33.5g of p-nitrobenzoic acid, 0.3g of benzyltriethylammonium chloride, and then add 95g of thionyl chloride into the reaction flask, stir evenly, heat to 80°C, and keep the temperature for 16 hours. Excessive thionyl chloride was distilled under reduced pressure to obtain 36.27g of the product, the chromatographic content was 99.84%, and the yield was 97.50%.

Embodiment 2

[0026] Add 50g of p-nitrobenzoic acid, 0.075g of benzyltriethylammonium bromide, 125g of thionyl chloride into the reaction flask, stir evenly, heat to 80°C, and keep it warm for 15 hours. After the reaction is over, evaporate excess chlorine sulfoxide, then vacuum distillation to obtain product 54.12g, the chromatographic content is 99.85%, and the yield is 97.48%.

Embodiment 3

[0028] Add 100g of p-nitrobenzoic acid, 0.1g of benzyltriethylammonium bromide, and 200g of thionyl chloride into the reaction flask, stir well, heat to 85°C, keep warm for 13 hours, and when the reaction is over, evaporate excess chlorine sulfoxide, then vacuum distillation to obtain product 109.47g, the chromatographic content is 99.74%, and the yield is 98.58%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com