The synthetic method of dimethyl heptyl methylphosphonate

A technology of dimethyl heptyl methyl phosphonate and dimethyl methyl phosphonate, which is applied in the field of preparation of organophosphorus compounds, can solve problems such as difficulty in raw material metering, achieve reduction of various side reactions, high yield, and reduce equipment The effect of investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

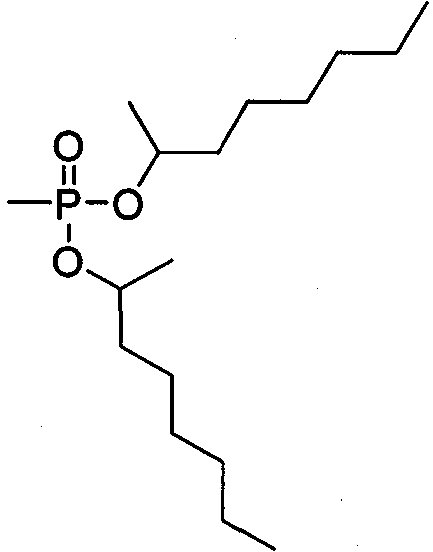

Image

Examples

Embodiment 1

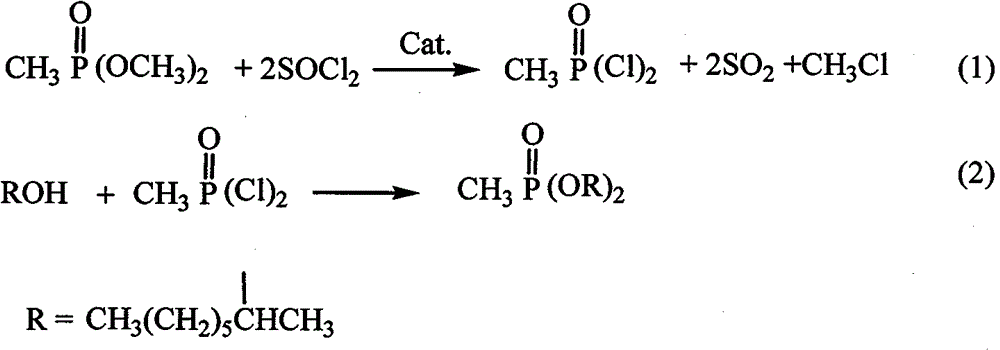

[0023] The method for synthesizing dimethylheptyl methylphosphonate of the present invention includes the following steps:

[0024] A. Add the acyl chlorination reagent to the reaction vessel. The acyl chlorination reagent is one of thionyl chloride, phosphorus pentachloride, and triphosgene. Add dimethyl methylphosphonate (DMMP) dropwise to the reaction vessel at room temperature. In the acyl chlorination reagent, with mol as the unit of measurement, the dosage of the acyl chlorination reagent is 2 times or 2.5 times or 3 times or 3.5 times or 4 times or 4.5 times or 5 times that of dimethyl methylphosphonate (DMMP), and Add a catalytic amount of catalyst, the catalyst is N,N-disubstituted formamide or N-containing aromatic heterocyclic ring or N-substituted N-containing aromatic heterocyclic ring or tertiary amine. Stir uniformly at room temperature, and then raise the temperature in the reaction vessel to 60 ℃ or 150℃, heat preservation and reaction for 1.5h or 2.5h or 2.5h, t...

Embodiment 2

[0029] The method for synthesizing dimethylheptyl methylphosphonate of the present invention includes the following steps:

[0030] (1) Acid chlorination reaction: Add a mixture of 124.08g (1mol) of dimethyl methylphosphonate and 0.8g of pyridine (0.01mol) to 520.6gPCl at 20°C. 5 (2.5mol), keep at room temperature and stir for 1 hour, warm to 80°C, keep reaction for 2 hours, collect the substance with boiling point 56-57°C / 14mmHg by vacuum distillation to obtain methylphosphonic dichloride, yield 94.2%, purity 98.1%.

[0031] (2) Esterification reaction: Under stirring, 14.9g methylphosphonic dichloride (0.1mol) was slowly added to 65.1g secondary octanol (0.5mol), the generated HCl gas was absorbed by lye, and the generated The methyl chloride is collected. React at room temperature (about 30°C) for 45 minutes, then at 55°C for 1.5 hours, and finally at 85°C for 2 hours.

[0032] (3) Post-treatment: the reaction solution was cooled to room temperature, washed with water to neutrali...

Embodiment 3

[0036] The method for synthesizing dimethylheptyl methylphosphonate of the present invention includes the following steps:

[0037] (1) Chlorination reaction: Add a mixture of 124.08g of dimethyl methylphosphonate (1mol) and 0.73g of DMF (0.01mol) slowly dropwise to 297.5g of thionyl chloride (2.5mol), and heat to reflux, After keeping the temperature for 4 hours and cooling the reaction liquid, the substance with the boiling point of 56-57° C. / 14mmHg is collected by vacuum distillation to obtain methylphosphonic dichloride with a yield of 96.4% and a purity of 98.5%.

[0038] (2) Esterification reaction: Under stirring, 14.9g methylphosphonic dichloride (0.1mol) is slowly added to 78.1g secondary octanol (0.6mol), the generated HCl gas is absorbed by lye, and the generated The methyl chloride is collected. React at room temperature (about 30°C) for 45 minutes, then at 55°C for 1.5 hours, and finally at 85°C for 2 hours.

[0039] (3) Post-treatment: the reaction solution was cooled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com