Biological compound potash fertilizer and preparation method thereof

A technology of compound potash fertilizer and biological potash fertilizer is applied in the field of fertilizers, which can solve the problems of limited amount of chemical fertilizer added, difficult survival of effective active bacteria, inability to fully satisfy crop growth, etc., and achieve the effect of excellent technical effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1 solid-state fermentation prepares biological compound potassium fertilizer (1)

[0031] 1) Preparation of fermentation bottom material

[0032] The potassium feldspar of 1 weight part, the agricultural and sideline processing waste of 5 weight parts (edible fungus slag, shrimp shell, bran, distiller's grains are mixed according to the ratio of 4:1:1:1), 0.5 weight part of flour, sulfuric acid The mixture of ammonium and MgSO4 (the weight ratio of flour, ammonium sulfate and MgSO4 is 100:10:1), and 10 parts by weight of water are respectively sterilized in a rotary steamer at 100° C. for 30 minutes, mixed evenly, and fermented Primer.

[0033] 2) Seed preparation

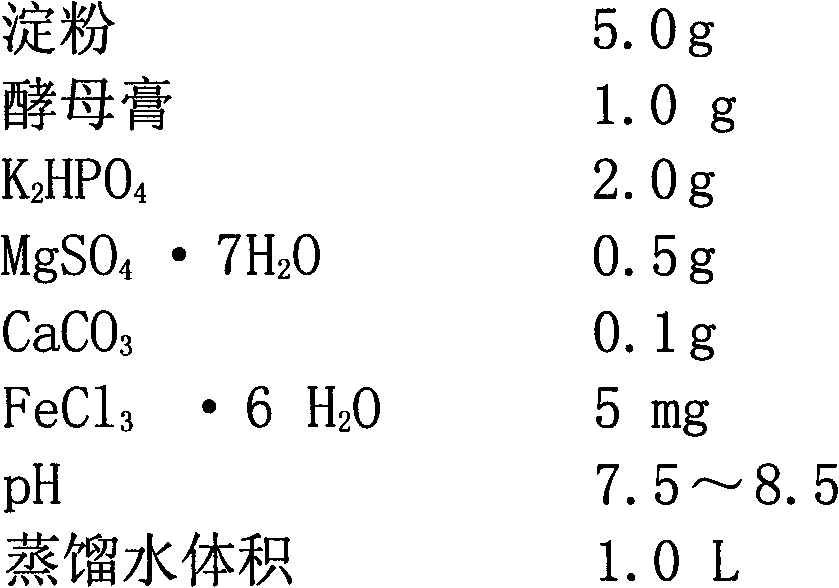

[0034] Inoculate Bacillus circulans CGMCC No.5155 in the following seed medium to obtain liquid seeds, and the number of viable bacteria is not less than 200 million / mL. The seed medium is as follows:

[0035]

[0036] 3) Preparation of biological potash fertilizer

[0037] The liquid seed...

Embodiment 2

[0045] Embodiment 2 solid-state fermentation prepares biological compound potassium fertilizer (two)

[0046] 1) Preparation of fermentation bottom material

[0047] With the montmorillonite of 5 parts by weight, the agricultural and sideline processing waste of 15 parts by weight (mixing according to the ratio of edible fungus slag, shrimp shells, corn dregs 4: 1: 2), corn flour of 5 parts by weight, ammonium sulfate and The mixture of MgSO4 (the weight ratio of flour, ammonium sulfate and MgSO4 is 100:8:0.8), and 25 parts by weight of water were sterilized at 120° C. for 30 minutes in a rotary steamer respectively, and packed into autoclavable polystyrene Acrylic plastic bags, (for example, 250g of dry materials per bag), promptly make the fermentation bottom material.

[0048] 2) Seed preparation

[0049] Inoculate Bacillus circulans CGMCC No.5155 into the seed medium to obtain solid seeds, the number of viable bacteria of which is not less than 500 million / g. The formul...

Embodiment 3

[0056] Embodiment 3 solid-state fermentation prepares biological compound potassium fertilizer (three)

[0057] 1) Preparation of fermentation bottom material

[0058] With 2 parts by weight of glauconite, 11 parts by weight of agricultural and sideline processing waste (mixed according to the ratio of edible fungus residue, shrimp shell, and bran 4:1:2), 1 part by weight of bean cake powder, ammonium sulfate and MgSO 4 (the weight ratio of flour, ammonium sulfate and MgSO4 is 100:9:0.9), and 17 parts by weight of water are sterilized in a rotary steamer at 120°C for 30 minutes, and then mixed evenly to obtain the fermentation bottom material.

[0059] 2) Seed preparation

[0060] Bacillus circulans CGMCC No.5155 was inoculated in the seed culture medium (same as in Example 1) to obtain liquid seeds with a viable count of not less than 200 million / mL.

[0061] 3) Preparation of biological potash fertilizer

[0062] Add the liquid seeds of the above-mentioned Bacillus circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com