Method for producing extracellular production and recombination beta-cyclodextrin transferase

A cyclodextrin and production method technology, applied in the field of fermentation engineering, can solve the problems of high industrial application cost and low enzyme activity, and achieve the effects of fewer steps, improved production efficiency, and shorter time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

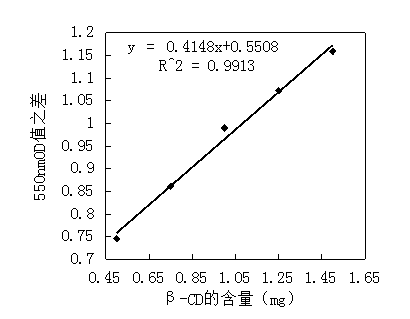

Image

Examples

Embodiment 1

[0033] 1. Escherichia coli E. Coli Construction of BL21(DE3)(pET28(+) / cgt): source Paenibacillus sp The β-cyclodextrin glucosyltransferase gene of XW-6-66 (Xie Zhenrong, Zhao Sanjun, Tang Xianghua, etc.. Source Paenibacillus sp . Cloning of β-cyclodextrin glucosyltransferase gene and its expression in Escherichia coli[J]. Food Science and Technology, 2010, 35(11): 16~19.) was inserted into plasmid pET28(+) to construct the expression The vector pET28(+) / cgt was transformed into host bacteria E. Coli BL21(DE3);

[0034] 2. Seed culture stage: insert the above-mentioned Escherichia coli strains preserved in -80°C glycerol into the seed medium, the seed medium is: 5g / L yeast powder, 10g / L peptone, 10g / L NaCl, kanamycin 0.05 mg / ml, pH 7.0, cultivated for 12 hours using a constant temperature incubation shaker, the rotation speed was 150 rpm, and the temperature was 37 °C;

[0035] 3. Fermentation stage: inoculate the strain into 200ml liquid fermentation medium according t...

Embodiment 2

[0038] 1 strain: Escherichia coli E. Coli BL21(DE3)(pET28(+) / cgt);

[0039] 2. Seed culture stage: insert the above-mentioned E. coli strains stored in -80°C glycerol into the seed medium, seed medium: 5.5g / L yeast powder, 10.5g / L peptone, 10.5g / L NaCl, kanamycin 0.05mg / ml, pH 7.2, cultivated for 12 hours using a constant temperature incubation shaker, the rotation speed was 150rpm, and the temperature was 37°C;

[0040] 3 Fermentation stage: inoculate the strain into 200ml liquid fermentation medium according to the inoculation amount of 2%, fermentation medium: 5.5g / L yeast powder, 10.5g / L peptone, 10.5g / L NaCl, 1.2mmol / L CaCl 2 , 2.25mmol / L MgSO 4 .7H2 O, kanamycin 0.05mg / ml, pH 7.2, placed in a constant temperature shaker for fermentation and culture, the temperature was controlled at 35°C, the rotation speed was controlled at 150rpm, and cultured for 8 hours;

[0041] 4. Induction stage: when the bacteria OD 600 When it reaches 1.4, add lactose to induce, ensure the ...

Embodiment 3

[0043] 1. Strains: Escherichia coli E. Coli BL21(DE3)(pET28(+) / cgt);

[0044] 2. Seed culture stage: Inoculate the above-mentioned Escherichia coli strains preserved in glycerol at -80°C into the seed medium. The seed culture is: 5g / L yeast powder, 10g / L peptone, 10g / L NaCl, 0.05mg kanamycin / ml, pH7.1, cultivated on a constant temperature culture shaker for 12 hours, with a rotation speed of 150rpm and a temperature of 37°C;

[0045] 3. Fermentation stage: Inoculate the strain into 200ml liquid fermentation medium according to the inoculation amount of 2%. The fermentation medium is: 5g / L yeast powder, 10g / L peptone, 10g / L NaCl, 1.2mmol / L CaCl 2 , 2.5mmol / L MgSO 4 .7H 2 O, kanamycin 0.05mg / ml, pH 7.1, placed in a constant temperature shaker for fermentation and culture, the temperature was controlled at 36°C, the rotation speed was controlled at 150rpm, and cultured for 7 hours;

[0046] 4. Induction stage: when the bacteria OD 600 When it reaches 1.6, add lactose to in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com