Roasting rotary furnace

A short kiln and roasting technology, which is applied in the improvement field of roasting rotary kiln structure, can solve the problems of low production efficiency and low nickel recovery rate, and achieve the effects of simple structure, convenient processing and production, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

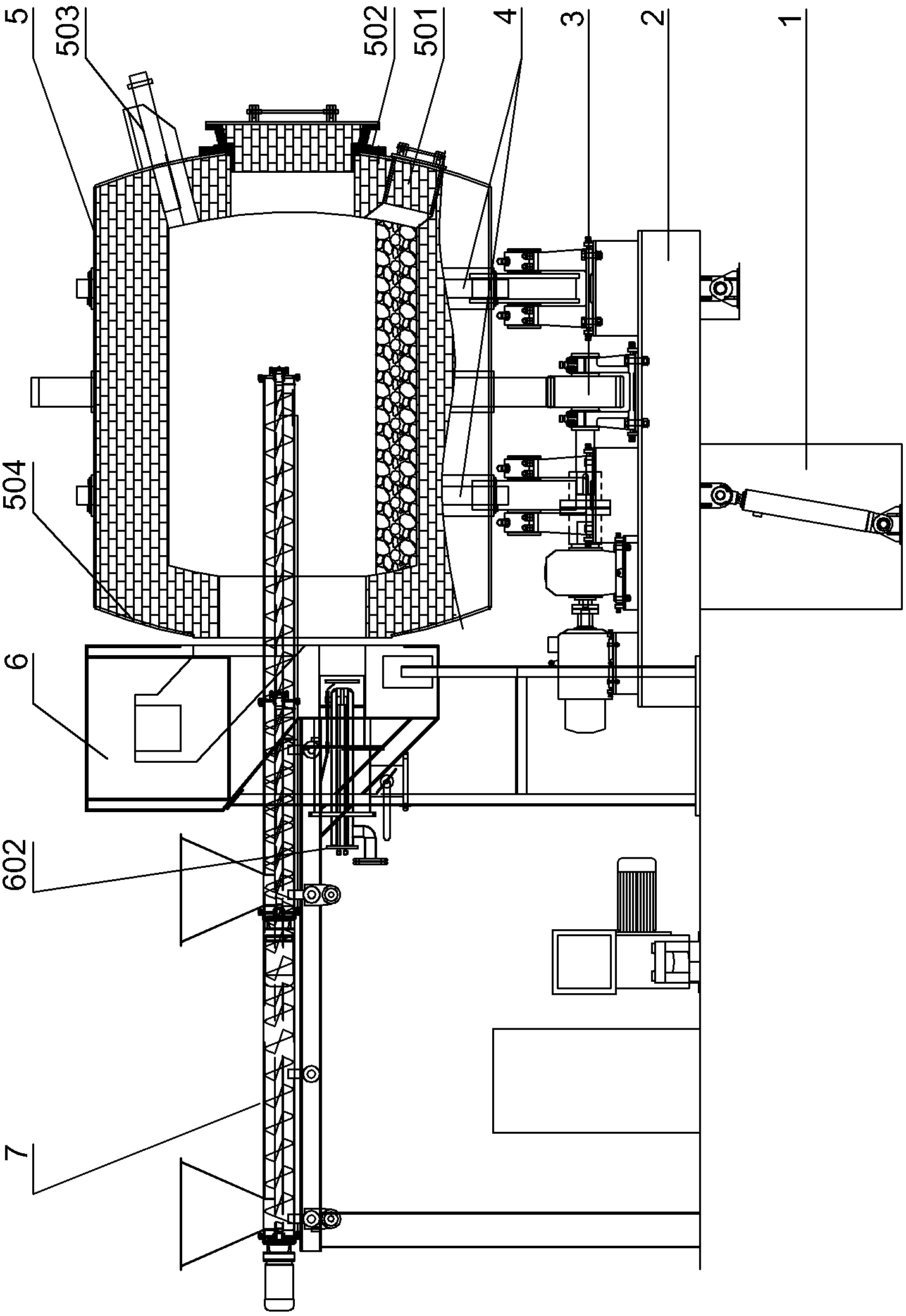

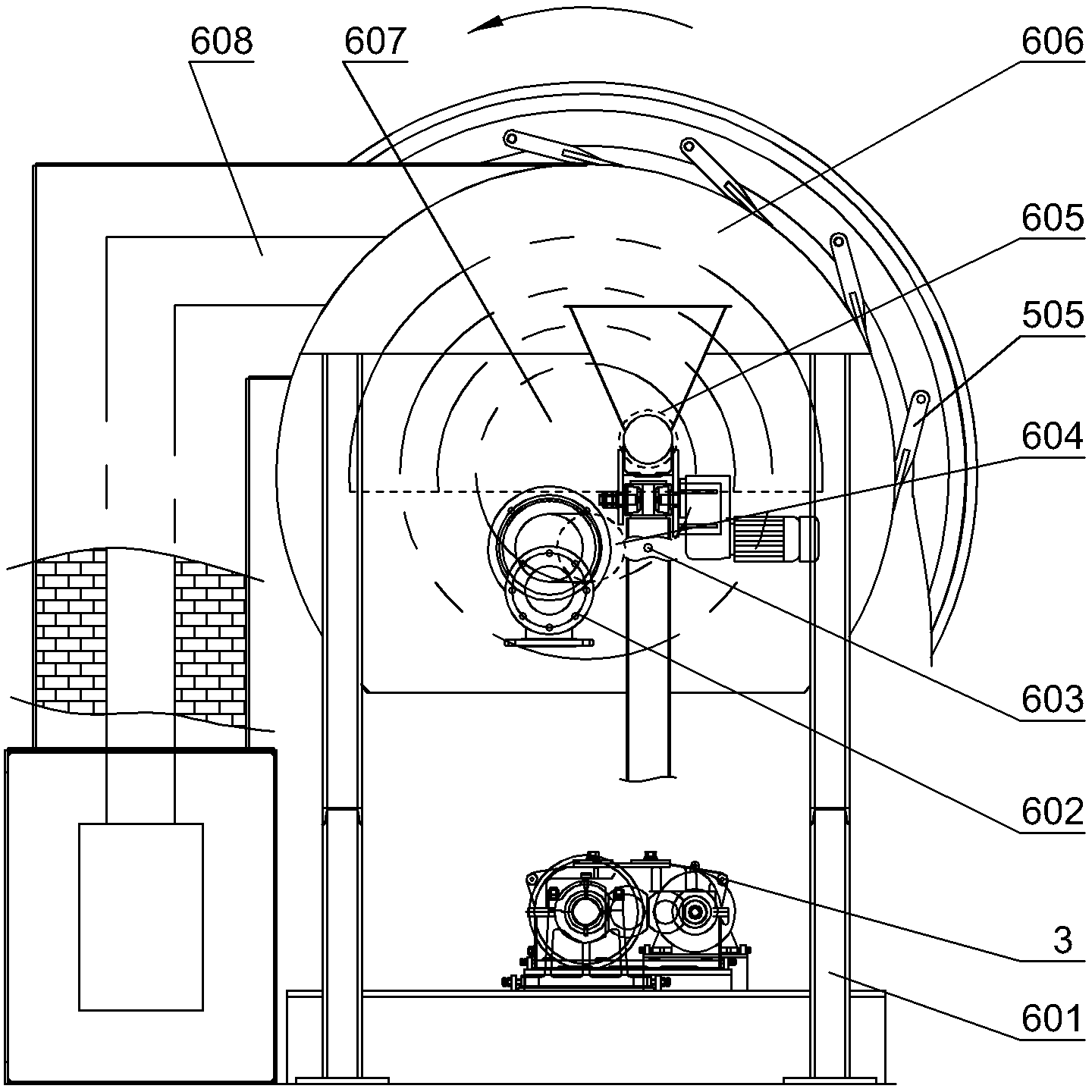

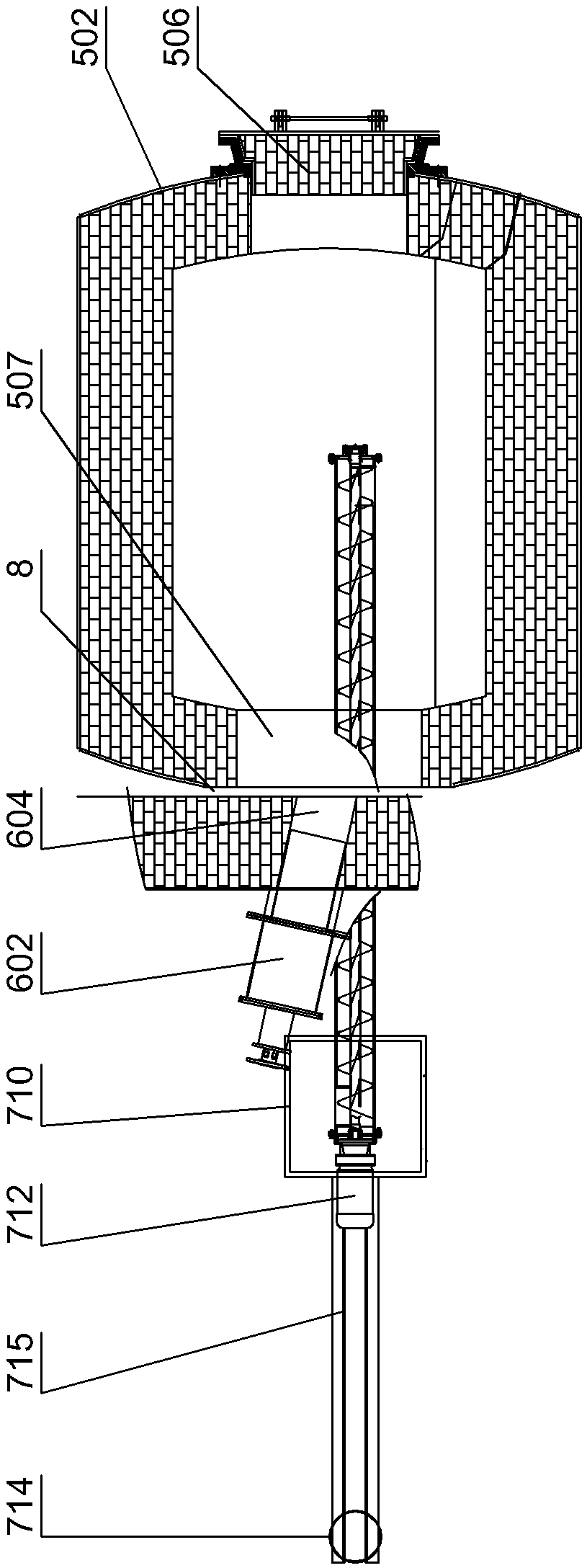

[0046] like figure 1 Shown is the structural schematic diagram of the roasting short kiln of the present invention. The present invention includes a kiln body 5, the base 2 of the kiln body 5 is provided with a supporting positioning mechanism 4 and a transmission mechanism 3, a hydraulic tipping mechanism 1 is provided under the base 2, and a solid discharge port 501 is provided at the discharge end 502 of the kiln body A kiln head cover 6 with a burner 602 is arranged on the side of the kiln body feed end 503 and the melt outlet 503 , and the side of the kiln head cover 6 is a feeding mechanism 7 .

[0047] The length of the kiln body 5 of the roasting short kiln of the present invention is 1.5m~15m, φ3~6m, and the thickness of the interior refractory brick layer 10 is 230~300mm; Figure 1-9 The roasting short kiln can use low-grade lateritic nickel-iron ore to prepare high-nickel concentrate. The equipment used is 2.3m in length and φ1.9m in length. The kiln body 5 is lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com