Contaminated soil ex-situ electrokinetic remediation device and method thereof

A technology of polluted soil and electric restoration, which is applied in the field of ex-situ restoration of polluted soil, which can solve problems such as increased power consumption, difficulty in acceptance work, and prolonged electric restoration time, achieving high work efficiency, low energy consumption, and a wide range of applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

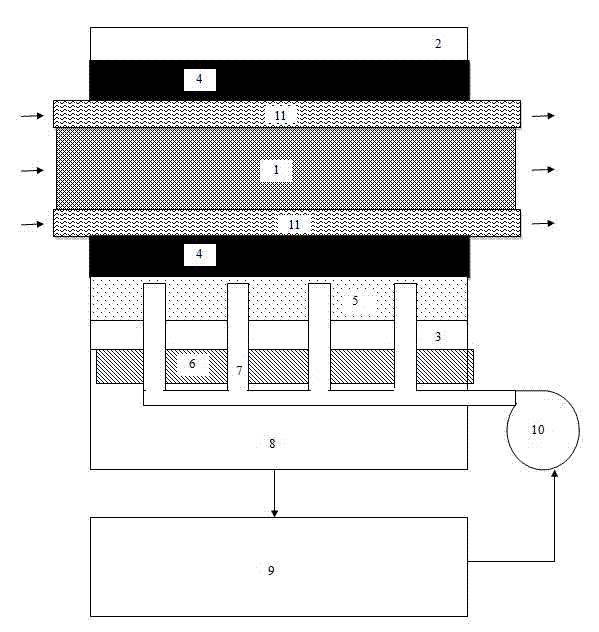

[0038] In this embodiment, the porous layer I4 includes upper and lower layers, which enclose the soil.

[0039] Further, the soil bearing system further includes two porous layers II 11 arranged in the porous layer I4, and the porous layer II 11 encloses soil. The porous layer I4 and / or the porous layer II 11 is a filter cloth, and the upper and lower electrodes 2, 3 are in contact with the filter cloth.

[0040] The method of the present embodiment comprises the following steps:

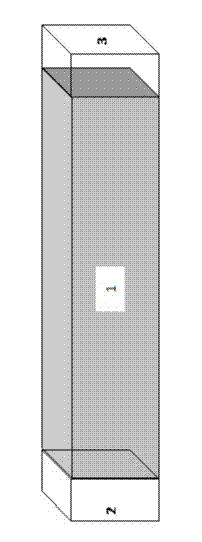

[0041] 1) Soil pretreatment: Contaminated soil containing pollutants is wet crushed, tempered and filtered to form mud, which is injected into the soil bearing system to form a thin mud layer 1 less than 10cm thick.

[0042] 2) Repair treatment: the upper and lower electrodes 2 and 3 are powered on, and the spray nozzle 7 sprays the working fluid upward. Under the action of the electric field, the pollutants migrate downward in the thin mud layer 1 and are washed out by the working fluid sprayed ...

Embodiment 2

[0046] In this embodiment, a water-permeable layer 5 is provided between the soil bearing system and the electrode working fluid spray system, and the spray nozzle 7 is embedded in the water-permeable layer 5 . The lower electrode 3 and the rigid water-permeable supporting layer 6 are installed in sequence below the water-permeable layer 5 .

[0047] Further, the electrode working fluid spray system also includes a sump 8 , a waste water treatment unit 9 , and a circulating water pump 10 . The working liquid sprayed out by the spray nozzle 7 flows downward into the sump 8 , is treated by the waste water treatment unit 9 , and then enters the spray nozzle 7 again through the circulating water pump 10 .

[0048] Compared with the method of Example 1, in the method of this example, in the step 1, the moisture content of the mud is 15-60%, and the thickness of the thin mud layer 1 is 0.2-10 cm. In the step 2, the washed working fluid enters the waste water treatment unit, and is ...

Embodiment 3

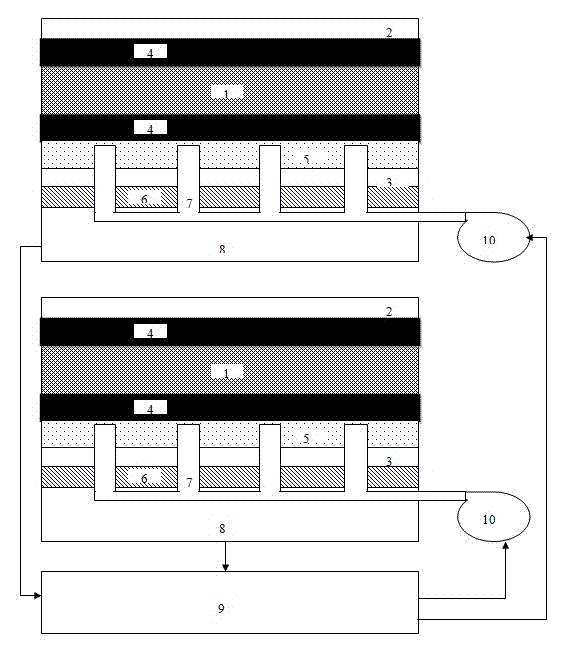

[0052] This embodiment provides a continuous production method, that is, on the basis of Embodiment 1 or 2, a pulling device is also included. Generally, the traction device is connected with a) the soil carrying system, or b) the electrode system and the electrode working fluid spraying system. Make a) the soil carrying system, and b) the electrode system and the electrode working fluid spray system undergo relative motion.

[0053] As a preferred manner, the soil bearing system further includes two porous layers II11 arranged in the porous layer I4, and the porous layer II11 encloses soil. The porous layer I4 and / or porous layer II11 is a filter cloth, and the upper and lower electrodes 2 and 3 are in contact with the filter cloth. The porous layer II11 is connected to the traction device.

[0054] The sequential method includes the following steps:

[0055] 1) Soil pretreatment: Contaminated soil containing pollutants is wet crushed, tempered and filtered to form mud, wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com