Method for protecting catalyst in tower during maintenance of ammonia synthesis tower

An ammonia synthesis tower and a synthesis tower technology, which is applied in the preparation/separation of ammonia, etc., can solve the problems of affecting the overall activity of the catalyst, loss of production benefits, and taking up too much time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for protecting the catalyst in the tower when the ammonia synthesis tower is overhauled comprises the following steps:

[0030] (1) Close the synthesis gas valve and replace the synthesis tower with nitrogen. The nitrogen passes through the shell of the heat exchanger into two branches and enters the synthesis tower for nitrogen replacement: one branch rises from the bottom central tube of the synthesis tower to the bottom of the synthesis tower. The upper part of the catalyst frame; another branch rises from the bottom of the synthesis tower to fill the annulus between the inner and outer cylinders of the synthesis tower;

[0031] (2) Connect the inlet and outlet pipes of the synthesis tower to nitrogen; the outlet pipe of the synthesis tower is connected to two channels of nitrogen through two deluge valves;

[0032] (3) Open the top cover of the synthesis tower, and put an annular nitrogen pipe with a diameter of 5 mm air outlets between the inner and outer ...

Embodiment 2

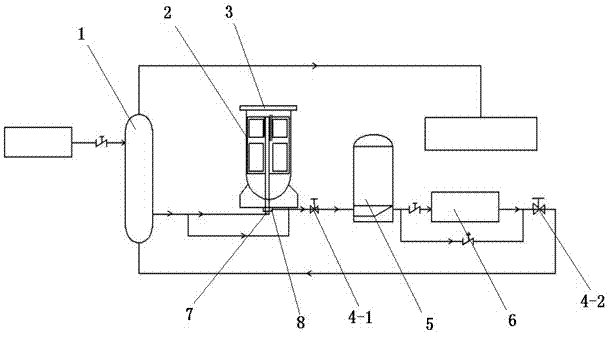

[0038] refer to figure 1 , Figure and schematic diagram of equipment structure are further described to protection method of the present invention:

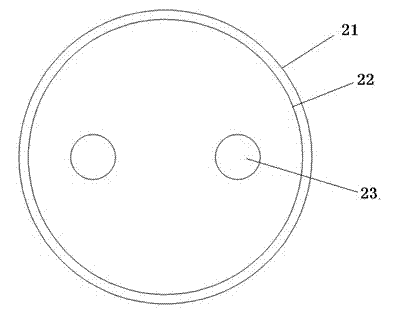

[0039] Close the synthesis gas valve and replace the nitrogen in the synthesis tower 2. The nitrogen is divided into two branches through the shell of the heat exchanger 1 and enters the synthesis tower 2 for nitrogen replacement: one branch rises from the bottom central tube of the synthesis tower 2 to the synthesis tower The upper part of the catalyst frame; another branch rises from the bottom of the synthesis tower to fill the annulus between the inner cylinder 22 and the outer cylinder 21 of the synthesis tower; the inlet pipe 7 and the outlet pipe 8 of the synthesis tower are all connected to nitrogen; wherein the outlet of the synthesis tower The pipe 8 is connected to two paths of nitrogen through the first deluge valve 4-1 located between the synthesis tower 2 and the heat exchanger 5, and the second deluge valve 4-2 at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com