Low-hardness pouring polyurethane rubber roller and production method thereof

A polyurethane, low-hardness technology, applied in the low-hardness cast polyurethane rubber roller and its production field, can solve the problem that the A material and the B material cannot achieve an accurate ratio, and improve the tensile strength and solvent resistance, turning and Good grinding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

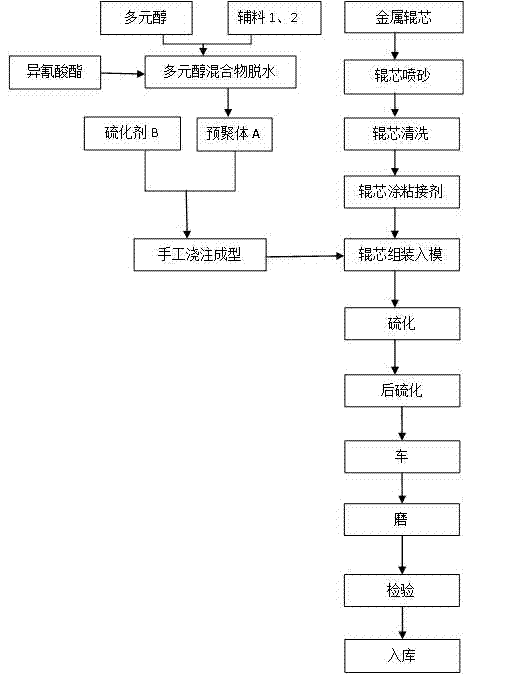

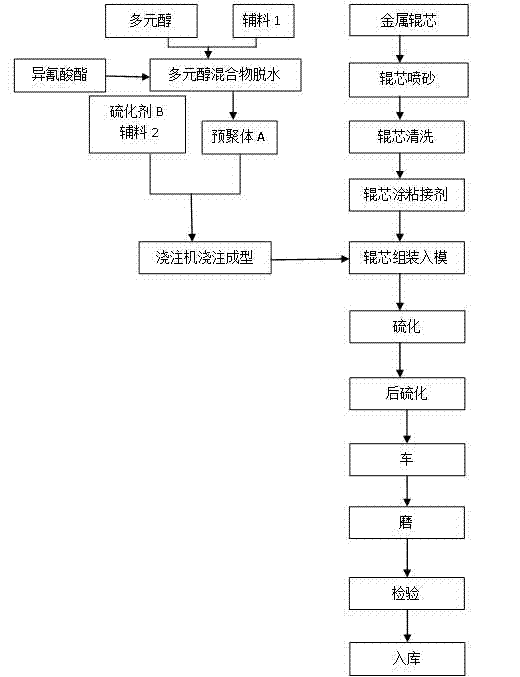

[0051]The production method of the low-hardness casting type polyurethane rubber roller of present embodiment 1, its steps are:

[0052] (1) Preparation of material A and material B

[0053] 1) Weigh 86kg of polyester polyol and 3.44kg of auxiliary material 1 calcium carbonate with a particle size of 400 mesh or more, stir well, grind twice with a colloid mill, then put it into the reaction kettle, stir and vacuumize at 110°C for dehydration After 1.5 hours, cool down to below 70°C for later use;

[0054] 2) Weigh about 17.7kg of isocyanate TDI and put it into the above reaction kettle, control the reaction temperature at 90~100°C, stir and vacuumize for 2 hours to obtain material A;

[0055] 3) Put the A material prepared in step 2) into the A tank corresponding to the elastomer pouring machine, stir again and evacuate for 1-3 hours, and set aside;

[0056] 4) Weigh 10.1kg of vulcanizing agent MOCA and 6.96kg of BBP, mix them, melt them at 110°C, put them into tank B of the...

Embodiment 2

[0076] The production method of the low-hardness casting type polyurethane rubber roller of present embodiment 2, its steps are:

[0077] (1) Preparation of material A and material B

[0078] 1) Weigh 45kg of polyε-caprolactone and 1.8kg of auxiliary material 1 calcium carbonate with a particle size of more than 400 meshes, stir well, grind twice with a colloid mill, put them into the reaction kettle, and stir and pump at 110°C Vacuum dehydration for 1.5 hours, cooled to below 70°C for later use;

[0079] 2) Weigh about 9.26kg of isocyanate TDI and put it into the above reaction kettle, control the reaction temperature at 90~100°C, stir and vacuumize for 2 hours to obtain material A;

[0080] 3) Put the A material prepared in step 2) into the A tank corresponding to the elastomer pouring machine, stir again and evacuate for 1-3 hours, and set aside;

[0081] 4) Weigh 5.32 kg of vulcanizing agent MOCA and 4.48 kg of BBP, mix them, melt them at 110°C and put them into tank B o...

Embodiment 3

[0101] (1) Preparation of material A and material B

[0102] 1) Weigh 125kg of polyester polyol and 5kg of auxiliary material 1 calcium carbonate with a particle size above 450 mesh, stir well, grind twice with a colloid mill, put it into the reaction kettle, stir and vacuum dehydrate at 110°C for 1.5 Hours, cooled to below 70°C for later use;

[0103] 2) Weigh about 25.73kg of isocyanate TDI and put it into the above reaction kettle, control the reaction temperature at 90~100°C, stir and vacuumize for 2 hours to obtain material A;

[0104] 3) Put the A material prepared in step 2) into the A tank corresponding to the elastomer pouring machine, stir again and evacuate for 1-3 hours, and set aside;

[0105] 4) Weigh 14.6kg of vulcanizing agent MOCA and 25.7kg of BBP, mix them, melt them at 110°C, put them into tank B of the pouring machine, stir and vacuumize for 2 hours, and obtain material B for later use;

[0106] (2) Roll core preparation

[0107] Select the metal roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com