Reversible thermochromic microcapsule and preparation method thereof

A thermochromic and microcapsule technology, applied in the directions of microcapsule preparation, microsphere preparation, color-changing fluorescent materials, etc., can solve the problems of high price of reversible thermochromic pens, difficulty in ink market promotion, increase in ink cost, etc. Mass production, increased color intensity, reduced usage effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0068] The present invention also provides a preparation method of reversible thermochromic microcapsules, comprising the following steps:

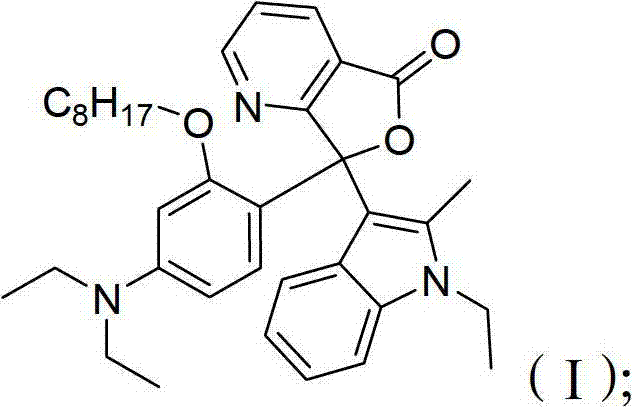

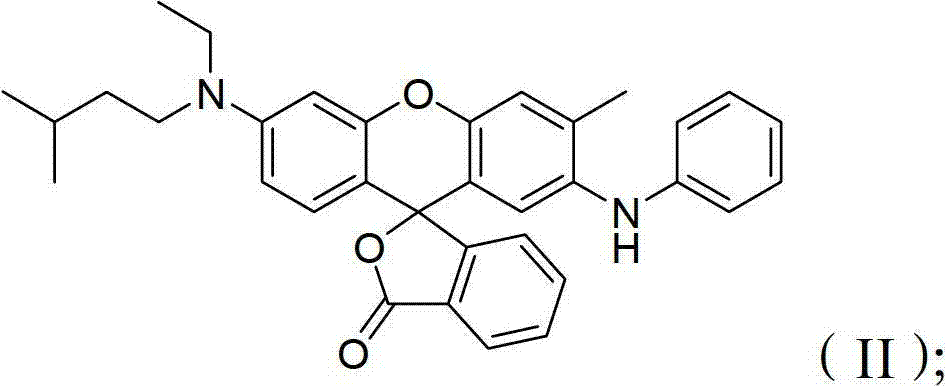

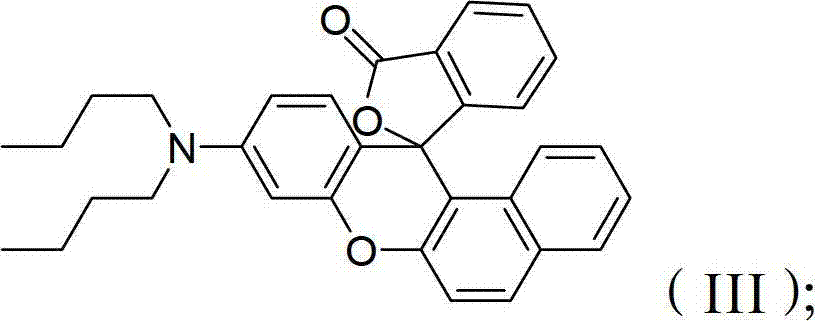

[0069] Mix 3-6 parts by weight of the first leuco dye, 0.3-0.4 parts by weight of the second leuco dye, 6-7 parts by weight of the developer and 30-40 parts by weight of the ester compound, and heat to obtain a molten a mixture; the first leuco dye is fluoran dye, phenylindolyl azepine 2-benzofuranone, phenylindolyl phthalide or phenyl aza phthalide; the second leuco dye It is a leuco dye with a melting point between 80°C and 100°C; the developer is bisphenol F and phthalimide;

[0070] mixing the molten mixture with an aqueous solution of styrene-maleic anhydride copolymer and emulsifying to obtain an emulsion with a particle size of the molten mixture below 8 μm;

[0071] The emulsion is mixed with the urea-formaldehyde resin prepolymer and cured to obtain reversible thermochromic microcapsules.

[0072] According to the above parts b...

Embodiment 1

[0086] 6 parts by weight of 1,3-dimethyl-6-dibutylaminofluorane, 0.3 parts by weight of CK-16, 4 parts by weight of bisphenol F, 2 parts by weight of phthalimide and 30 4-benzyloxyphenethyl decanoate in parts by weight is mixed, and after being heated to 110° C., a molten mixture is obtained;

[0087] The molten mixture is used as the oil phase, and 180 parts by weight of a 5% SMA aqueous solution is used as the continuous phase, and high-speed shear emulsification is carried out at a temperature of 60 ° C. After 30 minutes, the particle size of the oil phase is 2 μm to 3 μm. lotion;

[0088] Add 30 parts by weight of urea-formaldehyde resin prepolymer to the emulsion, solidify at a temperature of 80° C., and obtain reversible thermochromic microcapsules after 2 hours.

[0089] The average particle size of the reversible thermochromic microcapsules is 2.5 μm; the reversible thermochromic microcapsules change from orange to colorless through temperature changes, the complete d...

Embodiment 2

[0091] 6 parts by weight of 1,3-dimethyl-6-dibutylaminofluorane, 0.3 parts by weight of CK-37, 4 parts by weight of bisphenol F, 2 parts by weight of phthalimide and 30 4-benzyloxyphenethyl decanoate in parts by weight is mixed, and after being heated to 110° C., a molten mixture is obtained;

[0092] The molten mixture is used as the oil phase, and 180 parts by weight of a 5% SMA aqueous solution is used as the continuous phase, and high-speed shear emulsification is carried out at a temperature of 70 ° C. After 30 minutes, the particle size of the oil phase is 2 μm to 3 μm. lotion;

[0093] Add 30 parts by weight of urea-formaldehyde resin prepolymer to the emulsion, solidify at a temperature of 85° C., and obtain reversible thermochromic microcapsules after 2 hours.

[0094] The average particle size of the reversible thermochromic microcapsules is 2.0 μm; the reversible thermochromic microcapsules change from orange to colorless through temperature changes, the complete d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com