Preparation method for microcrystalline cellulose

A technology of microcrystalline cellulose and waste residue, applied in the direction of pulping with inorganic alkali, pulp bleaching, etc., can solve problems such as air pollution, waste of cultivated land, and great environmental hazards, and achieve the effect of eliminating pollution and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

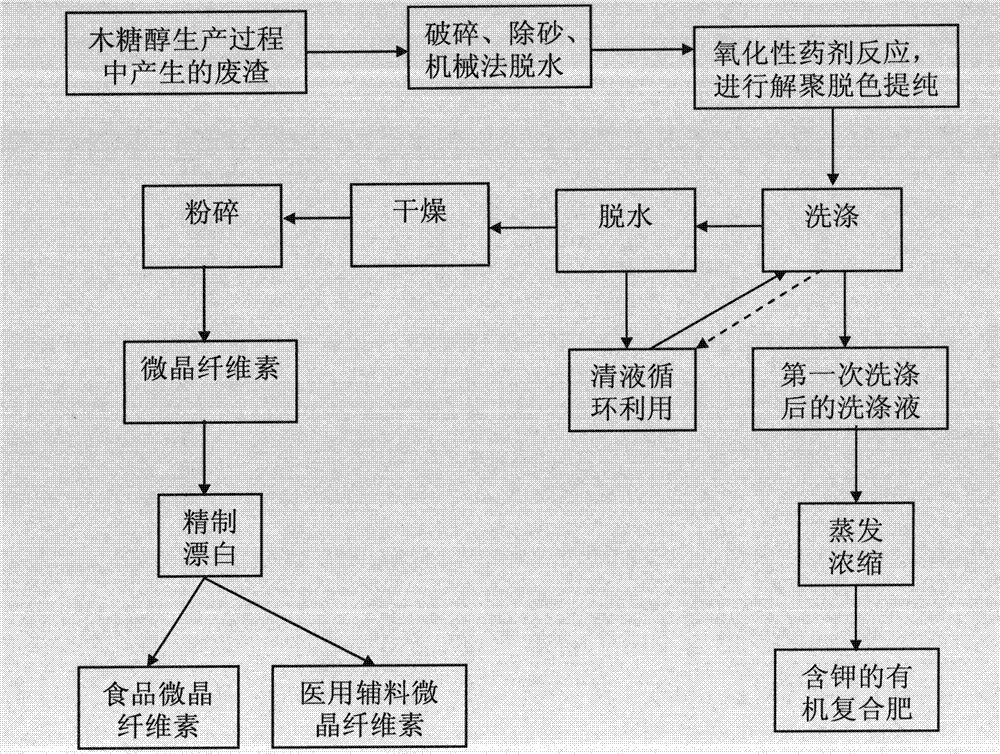

Method used

Image

Examples

Embodiment 1

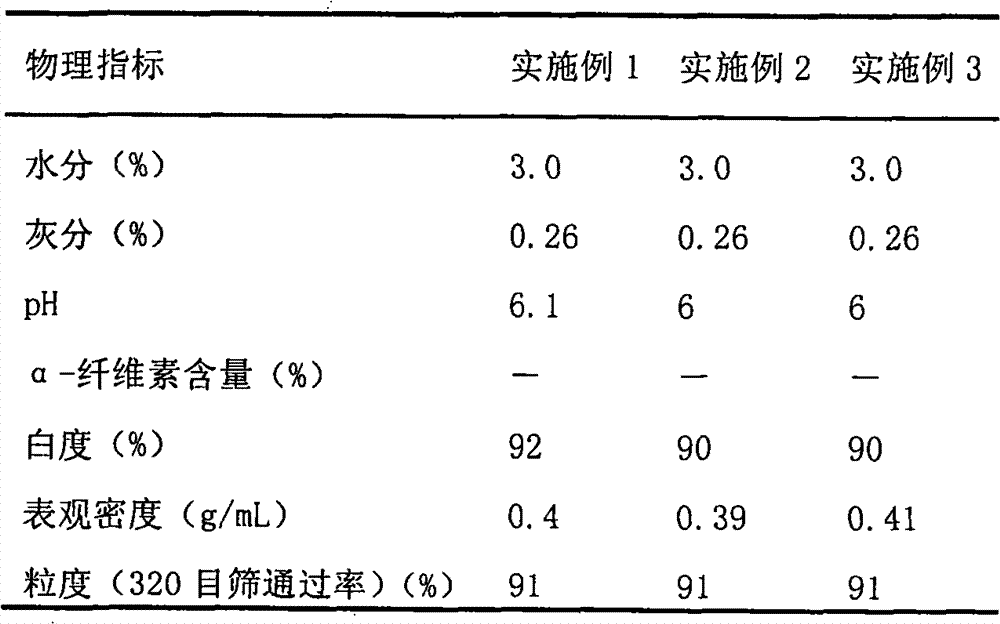

[0028] The waste residue in the xylitol production process is crushed and desanded, and then dehydrated by mechanical method until the water weight content is equal to 45%; take 100kg of the above-mentioned waste residue, add KOH and H 2 o 2 130kg of the mixed solution, wherein, KOH and H 2 o 2 The weight ratio of KOH is 3:1, the weight percentage of KOH is 8.8%, and the reaction is carried out at normal pressure and 60° C. for 5 minutes; after that, the reaction product is washed 5 times, wherein the washing liquid after the first washing is carried out Evaporating and concentrating to obtain potassium-containing organic compound fertilizers, the washing liquid produced in the 2nd to 5th washings is treated and recycled to the washing step for use as a detergent, and the water generated after the product is dehydrated is recycled to the washing step for use as a detergent; The product obtained by washing is dehydrated, dried and pulverized to obtain microcrystalline cellulo...

Embodiment 2

[0030] The waste residue in the xylitol production process is crushed and desanded, and then dehydrated by mechanical method until the water weight content is equal to 5%; take 100kg of the above-mentioned waste residue, add KOH and H 2 o 2 The mixed solution 145kg, wherein, KOH and H 2 o 2 The weight ratio of KOH is 1:1, the weight percentage of KOH is 2%, and the reaction is carried out at normal pressure and 90° C. for 3 minutes; after that, the reaction product is washed 5 times, wherein the washing liquid after the first washing is carried out Evaporating and concentrating to obtain potassium-containing organic compound fertilizers, the washing liquid produced in the 2nd to 5th washings is treated and recycled to the washing step for use as a detergent, and the water generated after the product is dehydrated is recycled to the washing step for use as a detergent; The product obtained by washing is dehydrated, dried and pulverized to obtain microcrystalline cellulose.

Embodiment 3

[0032] The waste slag in the xylitol production process is crushed and desanded, and then dehydrated by mechanical method until the water weight content is equal to 15%; take 100kg of the above-mentioned waste slag, add KOH and H 2 o 2 The mixed solution of 175kg, wherein, KOH and H 2 o 2 The weight ratio of KOH is 3:1, the weight percentage of KOH is 6%, and the reaction is carried out at normal pressure and 50°C for 8 minutes; after that, the reaction product is washed 3 times, wherein the washing solution after the first washing is carried out Evaporating and concentrating to obtain potassium-containing organic compound fertilizer, the washing solution produced in the 2nd to 3rd washing is processed and recycled to the washing step for use as a detergent, and the water generated after the product is dehydrated is recycled to the washing step for use as a detergent; ; The product obtained by washing is dehydrated, dried and pulverized to obtain microcrystalline cellulose. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com