Automotive annular closed fuel saving device with variable magnetic field

A variable and annular technology, applied in the installation/connection of lubricant purification devices, magnetic separation, solid separation, etc., can solve the problems of wasting energy, increasing oil consumption, increasing maintenance costs, etc., to reduce wear, solve serious wear, The effect of extending engine life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

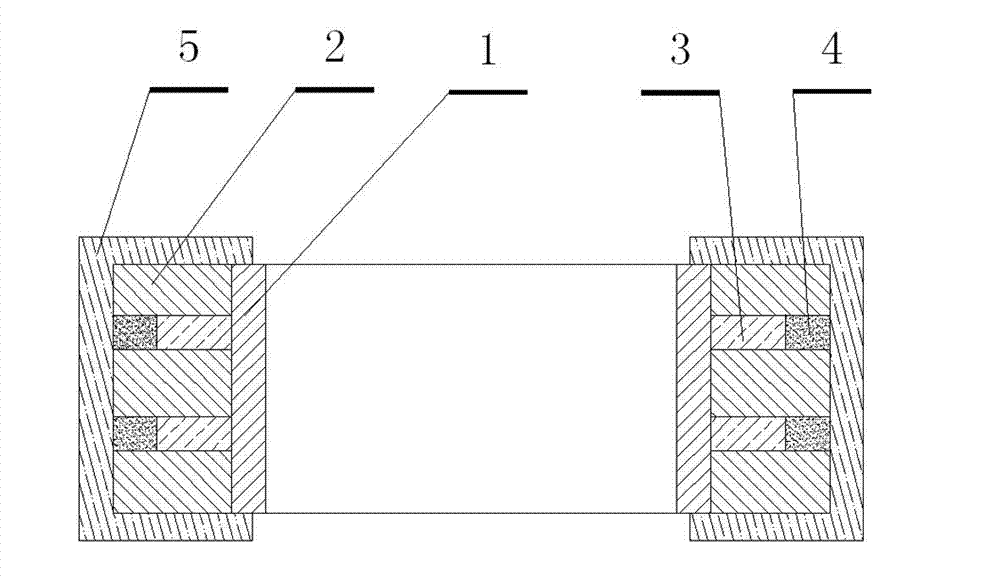

[0015] The automobile annular closed variable magnetic field fuel-saving device of the present invention comprises a ring 1 made of copper, the thickness of which is 0.1-0.2 mm, and the outer surface of the ring 1 is covered with a layer of 5 mm thick silica gel 2, so that A through hole is opened on the silica gel 2, and a magnet 3 and a magnetic variable material 4 are sequentially arranged in the through hole from inside to outside, and the magnetic variable material 4 has a thickness of 2 mm. The stainless steel sealing ring 5 is set on the outside of the silica gel 2 to seal the through hole. In the present invention, springs are arranged in one to two through holes on the silica gel to provide tension and prevent the device from falling off.

[0016] The variable magnetic permeability material 3 is composed of the following weight ratio: 5% copper, 20% iron, 20% ferrous oxide, 5% aluminum, 2% chromium, 18% quartz, and 30% silicone glue.

Embodiment 2

[0018] The automobile annular closed variable magnetic field fuel-saving device of the present invention comprises a ring 1 made of copper, the thickness of which is 0.1-0.2 mm, and the outer surface of the ring 1 is covered with a layer of 5 mm thick silica gel 2, so that A through hole is opened on the silica gel 2, and a magnet 3 and a magnetic variable material 4 are sequentially arranged in the through hole from inside to outside, and the magnetic variable material 4 has a thickness of 2 mm. The stainless steel sealing ring 5 is set on the outside of the silica gel 2 to seal the through hole. In the present invention, springs are arranged in one to two through holes on the silica gel to provide tension and prevent the device from falling off.

[0019] The variable magnetic permeability material 3 is composed of the following weight ratio: 4% copper, 15% iron, 20% ferrous oxide, 6% aluminum, 6% chromium, 20% quartz, and 29% silicone glue.

Embodiment 3

[0021] The automobile annular closed variable magnetic field fuel-saving device of the present invention comprises a ring 1 made of copper, the thickness of which is 0.1-0.2 mm, and the outer surface of the ring 1 is covered with a layer of 5 mm thick silica gel 2, so that A through hole is opened on the silica gel 2, and a magnet 3 and a magnetic variable material 4 are sequentially arranged in the through hole from inside to outside, and the magnetic variable material 4 has a thickness of 2 mm. The stainless steel sealing ring 5 is set on the outside of the silica gel 2 to seal the through hole. In the present invention, springs are arranged in one to two through holes on the silica gel to provide tension and prevent the device from falling off.

[0022] The variable magnetic permeability material 3 is composed of the following weight ratio: 3% copper, 20% iron, 20% ferrous oxide, 6% aluminum, 6% chromium, 20% quartz, and 25% silicone glue.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com