Drying method for lithium ion battery manufacture

A technology of lithium ion battery and drying method, which is applied in the field of drying lithium ion electrode materials, pole pieces or batteries, can solve the problem of several days or even longer (ten days, affecting the electrochemical performance and pass rate of the battery) , It is difficult to obtain the drying effect and other problems, so as to improve the quality and performance, shorten the drying time, and reduce the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

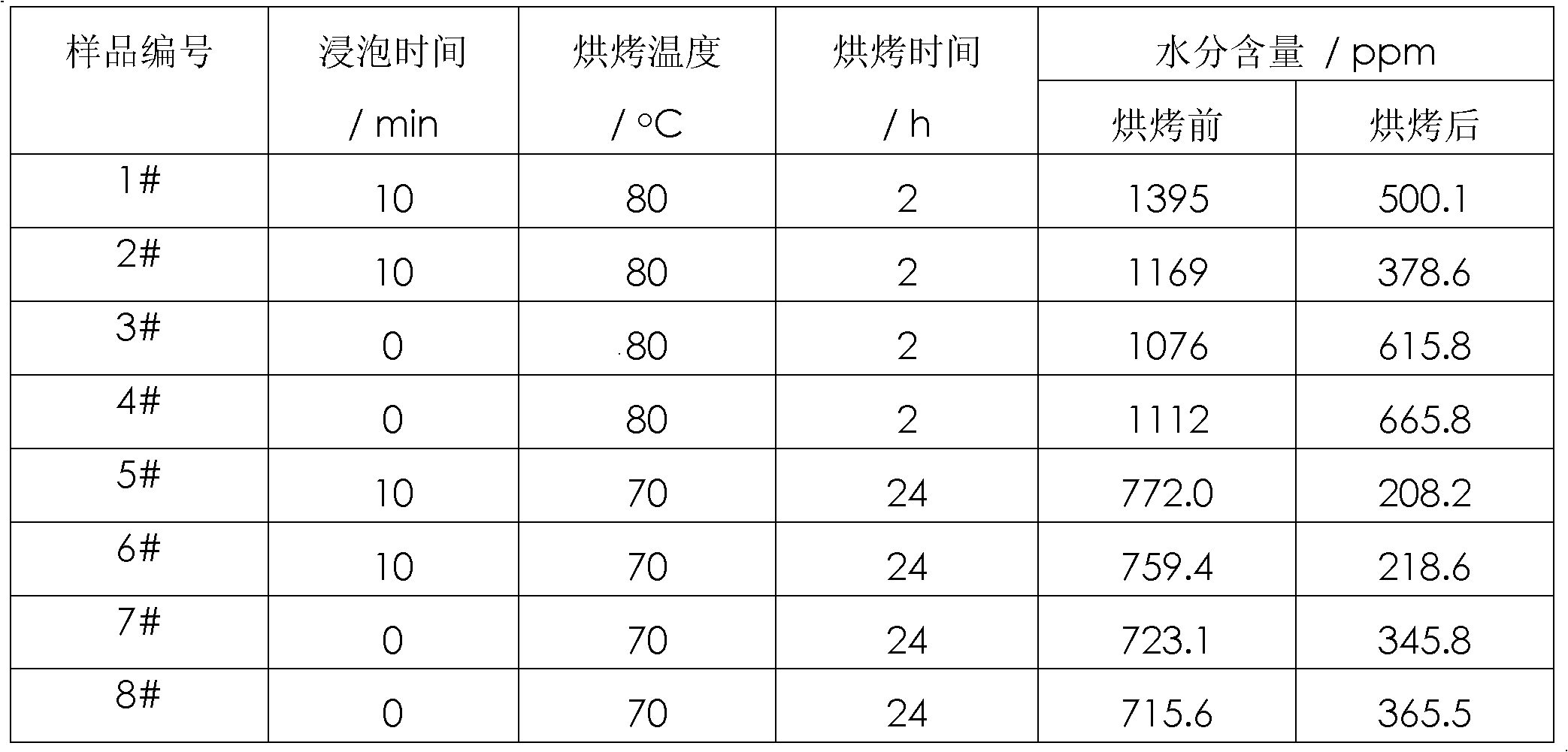

[0018] In this embodiment, the samples to be dried (1#-8#) use the same batch of 26650 battery cores (the positive electrode material is lithium iron phosphate, the negative electrode material is graphite, the positive electrode is an organic binder, and the negative electrode is an aqueous adhesive. agent), soak the roll core to be dried in absolute ethanol (water content < 20ppm) for a certain period of time, and then vacuum bake it at a certain temperature. The results of the moisture content of the battery core after drying are shown in Table 1.

[0019] Table 1

[0020]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com