Pneumatic type support system of primary mirror of astronomical telescope

A technology for an astronomical telescope and a support system, which is applied to the pneumatic active support system of the main mirror of the astronomical telescope and the active optical mirror support of the astronomical telescope, can solve the problems of high cost, high energy consumption, low travel and the like, and achieves wide adjustment range and energy consumption. Low, large stroke effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

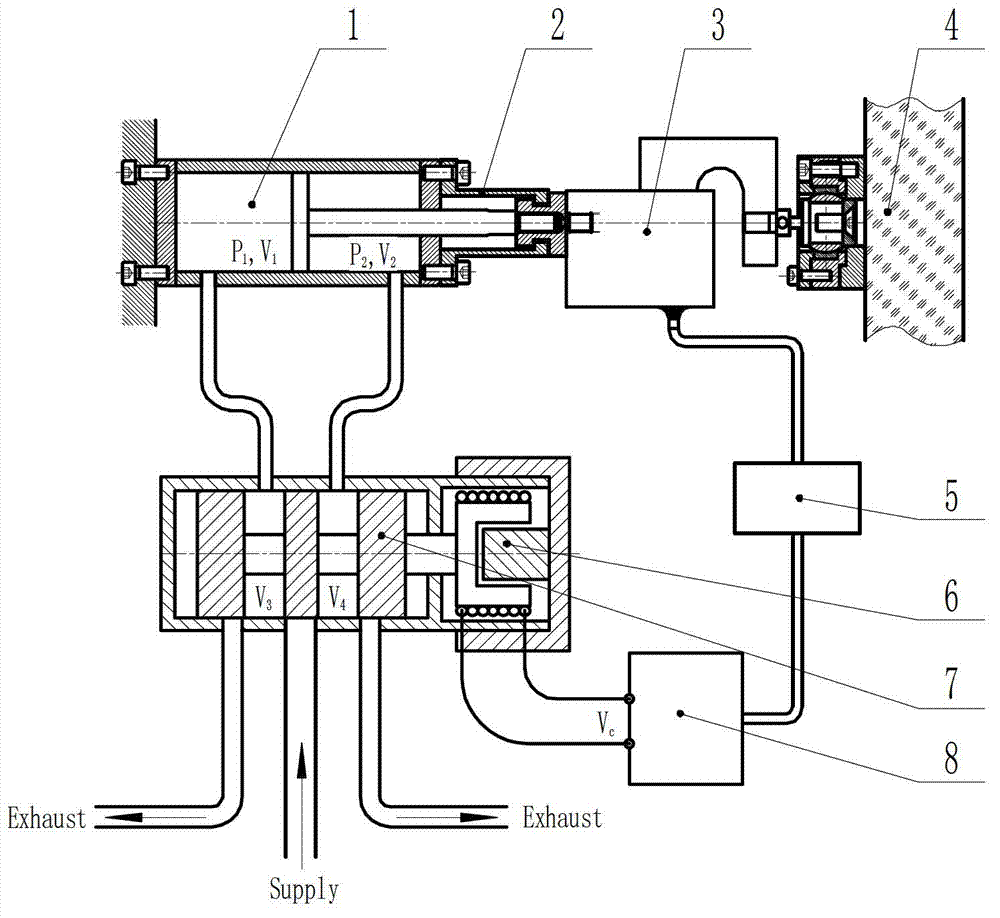

[0013] Embodiment 1, the pneumatic support system of astronomical telescope primary mirror, with reference to figure 1 : The force output end 2 of the pneumatic force actuator is connected with the mirror 4 through the force sensor 3. When the air compressor supplies air to the cylinder 1 through the electric-pneumatic proportional valve 7, adjust the control system 8 so that the output signal of the force sensor 3 When the force fed back to the control system 8 by the signal amplifier 5 is zero, the input voltage of the control system 8 to the coil of the electric-pneumatic proportional valve 7 is a balanced voltage, and its value is between 0 and 10V (electric-pneumatic proportional valve request input voltage signal value). When the force actuator is required to apply thrust to the mirror surface, increase the input voltage of the control system to the electro-pneumatic proportional valve 7, at this time, the current in the coil of the electro-pneumatic proportional valve 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com