Processing method for integrated cover plate glass of touch sensor

A touch sensor and cover glass technology, applied in glass manufacturing equipment, glass cutting devices, manufacturing tools, etc., can solve the problems of surface contamination, damage, and easy damage to touch screen sensors, and achieve the effect of strong adhesion and improved scars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

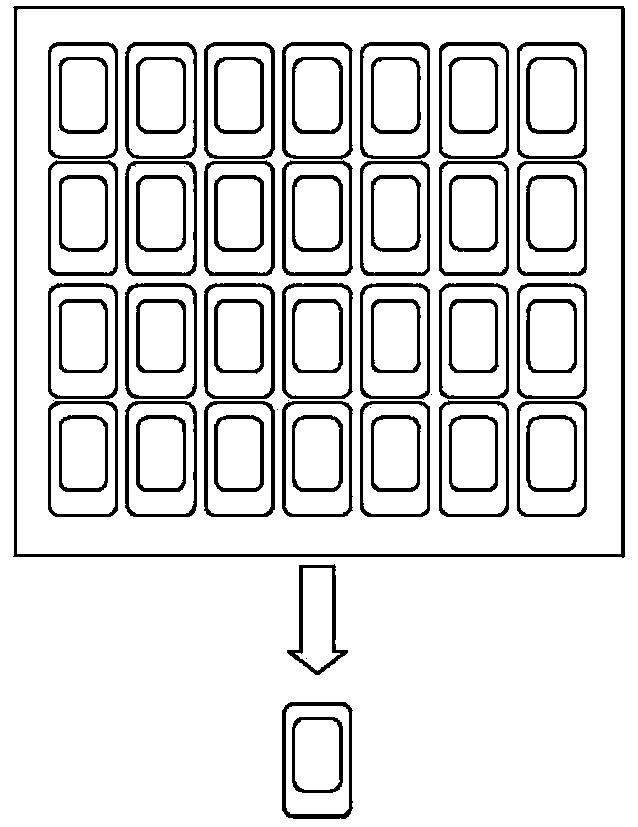

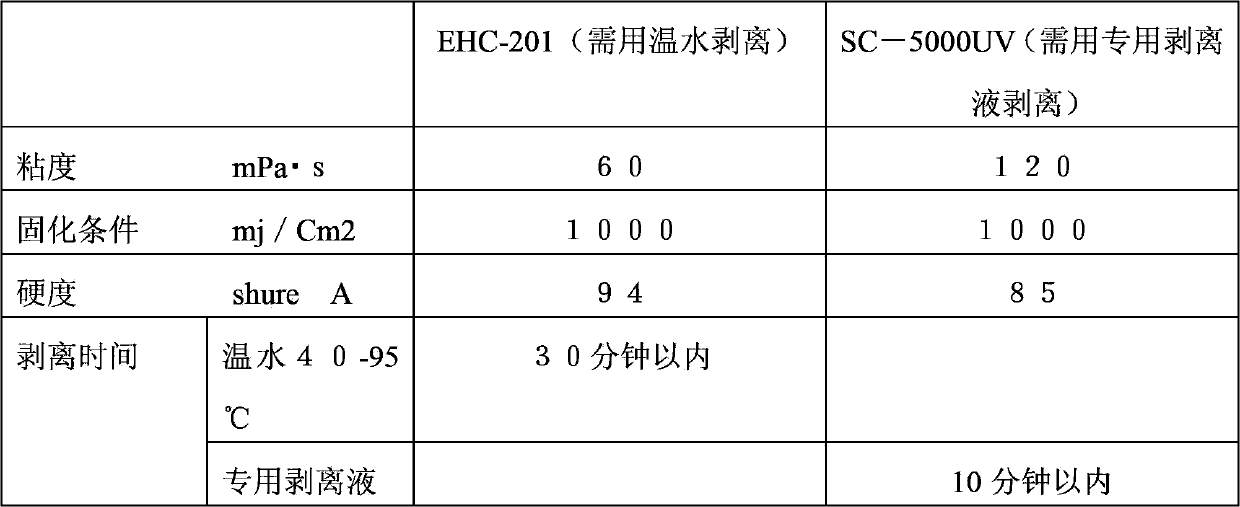

[0026] Use low-viscosity UV curing, warm water or special stripping liquid to peel off the resin, paste thin glass plates on both sides of OGS chemically strengthened large glass, or process thin resin plates that can pass through UV, then use warm water or special stripping liquid Perform stripping.

[0027] First, drop a low-viscosity UV-curable resin (viscosity below 1000mPa·s) on one side of OGS chemically strengthened large glass, and then press and bond it with a thin glass plate (thickness 0.03-0.7mm), or use UV-permeable The resin plate (thickness is 0.03 ~ 0.7mm) is pressure-bonded, so that the resin is evenly coated on the OGS chemically strengthened large glass and cured by ultraviolet radiation. The other side of the large sheet of OGS chemically strengthened glass is also processed in the same process, using a thin glass plate (thickness 0.03-0.7mm) for pressure bonding, or a resin plate (0.03-0.7mm) that can transmit ultraviolet rays (0.03-0.7mm). Combine to sol...

Embodiment 2

[0032] Use low-viscosity UV-cured, warm water or resin stripped by special stripping liquid, paste UV-permeable thin plate on one side of OGS chemically strengthened large glass plate with low-viscosity resin for curing, and paste UV-impermeable thin plate on the other side for curing , Peel off with warm water or a special stripping solution.

[0033] Drop a low-viscosity UV-curable resin (below 1000mPa·s) on the OGS chemically strengthened large glass, and then use a thin metal plate or resin plate (0.03-0.7mm) that cannot pass through UV to press and bond the resin to make the resin in OGS chemically strengthened. It is evenly coated on a strengthened large sheet of glass and cured by UV light. On the other side of the OGS chemically strengthened large glass, the same process is followed, dripping resin, and using a thin glass plate (thickness 0.03-0.7mm) or a resin plate (0.03-0.7mm) that can pass through ultraviolet rays. After both sides are bonded and cured, the OGS ch...

Embodiment 3

[0038] Use a low-viscosity resin on the bottom of the glass to paste a thin plate for curing (it can be a UV-transparent or impermeable thin plate, a thin glass plate, or a thin metal plate, or a thin resin plate), and paste a UV peeling on the upper part of the glass Adhesive tape protection.

[0039]Drop low-viscosity UV-curable resin (below 1000mPa·s) on the bottom of OGS chemically strengthened large glass, and then use a thin glass plate with a thickness of 0.03-0.7mm, or a thin metal plate, or a thin resin plate to press and bond the resin. Spread evenly on a glass substrate and cure by UV irradiation. After the UV peeling adhesive tape is pasted on the upper part of the OGS chemically strengthened large glass, the OGS chemically strengthened large glass is cut with a water jet. After the cut single OGS glass is irradiated with UV, the adhesive tape will fall off, and then warm water (40 -95°C) or soaked in a special stripping solution, the thin glass and UV curable res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com