Method for producing dimethyl disulfide by using methyl mercaptan oxidation method

A technology of dimethyl disulfide and methyl mercaptan, applied in the directions of hydrogenated polysulfide/polysulfide preparation, organic chemistry, etc., can solve the problem of high production cost, life-threatening operator, industrialized production not realized and reported, etc. problems, to achieve the effects of low production costs, significant social and economic benefits, and less emissions from the three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Implementation Method Principle

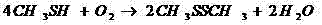

[0012] Methyl mercaptan reacts under the conditions of oxidizing agent, emulsifier and catalyst at corresponding temperature and pressure to generate dimethyl disulfide. Its chemical reaction mechanism is as follows:

[0013] Reaction Mechanism of Methyl Mercaptan and Oxygen Oxidation

[0014]

[0015] The specific operation steps are as follows:

[0016] The raw material is methyl mercaptan, the oxidant is oxygen, the catalyst is nitrogen dioxide, and the emulsifier is acetone, dimethylformamide or dimethyl sulfoxide.

[0017] Firstly, methyl mercaptan, oxygen, and nitrogen dioxide are passed into the tower reactor at a molar ratio of 4:1.25:0.2, and the oxidation reaction is carried out in the presence of an emulsifier. The molar ratio of methyl mercaptan to emulsifier is 1:10-30 ;The reaction temperature is 10~150℃, the pressure is 0.01~0.1MPa, the reaction yield is 86%~89%, and the conversion rate is 81%~86% (based on the inpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com