Electrical insulating material and high voltage equipment using it

A technology for electrical insulating materials and high-voltage equipment, applied in the direction of organic insulators, plastic/resin/wax insulators, etc., can solve the problems of increased dielectric constant, decreased mechanical properties such as heat resistance and breaking strength, and decreased resin properties, etc. To achieve the effect of excellent crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

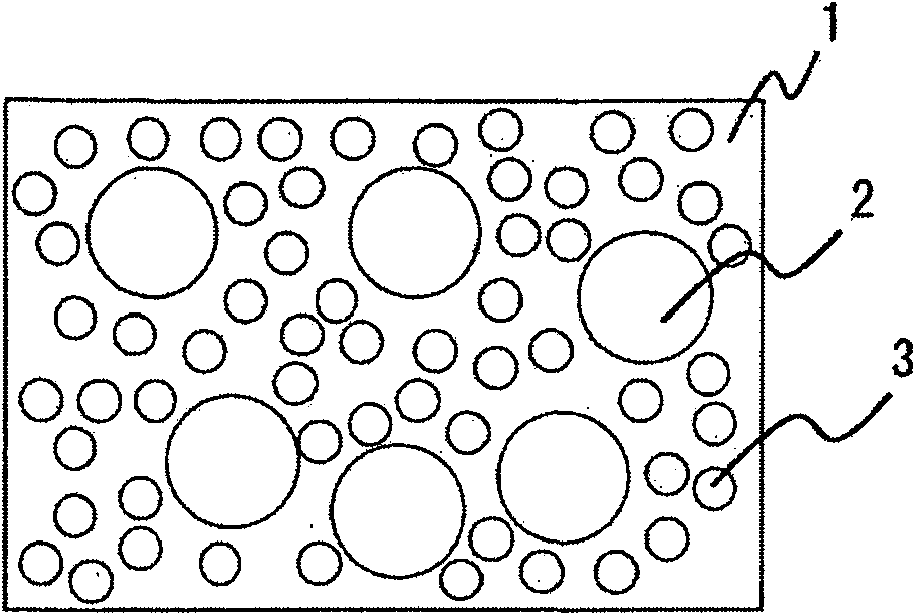

[0060] With respect to 100 parts by weight of epoxy resin (bisphenol A type and bisphenol F type), 10 parts by weight of radiation-crosslinked acrylonitrile butadiene rubber particles modified by carboxylic acid (average particle diameter 50-100nm), 415 parts by weight of pulverized silica as inorganic particles, acid anhydride curing agent, silane coupling agent, titanate coupling agent, and imidazole compound as a curing accelerator are heated to 80°C while applying sufficient shearing force , while mixing. After defoaming the formed mixed solution, it was cured under the heating conditions of 100° C. / 5 hours + 170° C. / 7 hours to form a cured product.

Embodiment 2

[0062] With respect to 100 parts by weight of epoxy resin (bisphenol A type and bisphenol F type), 10 parts by weight of radiation-crosslinked acrylonitrile butadiene rubber particles modified by carboxylic acid (average particle diameter 50-100nm), 300 parts by weight of pulverized silica as inorganic particles, acid anhydride curing agent, silane coupling agent, titanate coupling agent, and imidazole compound as a curing accelerator are heated to 80°C while applying sufficient shearing force , while mixing. After defoaming the formed mixed solution, it was cured under the heating conditions of 100° C. / 5 hours + 170° C. / 7 hours to form a cured product.

Embodiment 3

[0064] With respect to 100 parts by weight of epoxy resin (bisphenol A type and bisphenol F type), 8 parts by weight of radiation-crosslinked acrylonitrile butadiene rubber particles modified by carboxylic acid (average particle diameter 50-100nm), 600 parts by weight of pulverized silica as inorganic particles, an acid anhydride curing agent, a silane coupling agent, a titanate coupling agent, and an imidazole compound as a curing accelerator are heated to 80°C while applying sufficient shearing force , while mixing. After defoaming the formed mixed solution, it was cured under the heating conditions of 100° C. / 5 hours + 170° C. / 7 hours to form a cured product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com