Oily solvent-based dispersion of polytetrafluoroethylene, epoxy resin composition containing polytetrafluoroethylene, and cured product thereof

A polytetrafluoroethylene and oil-based solvent technology, which is applied in the field of oil-based solvent-based dispersions and can solve problems such as complex preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5 and comparative example 1~3

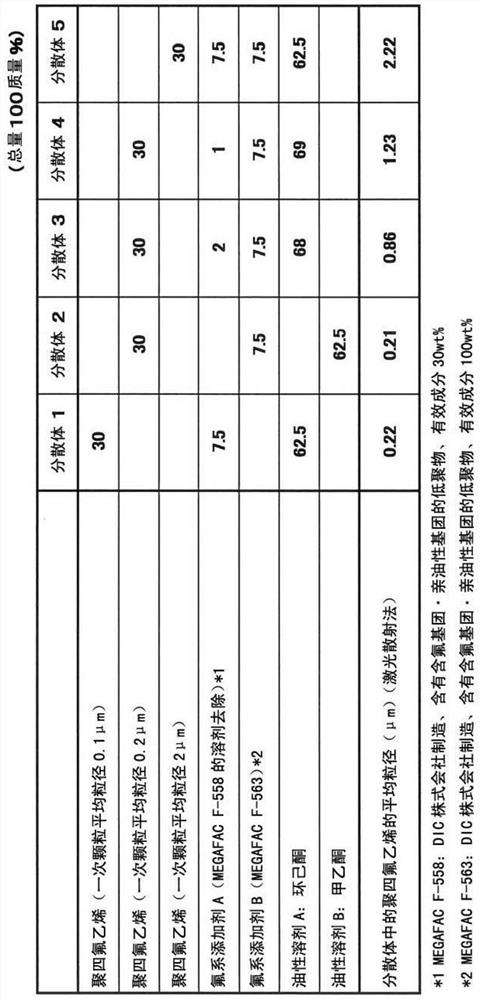

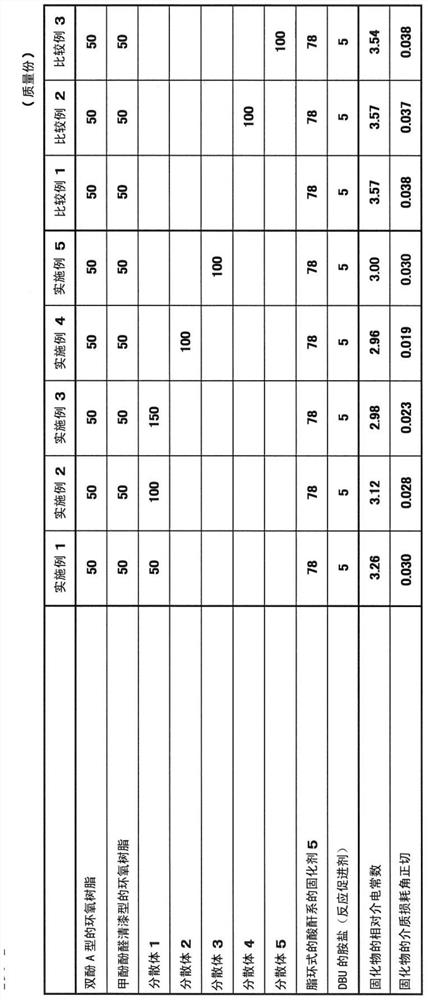

[0091][Examples 1-5 and Comparative Examples 1-3: Preparation of PTFE-containing epoxy resin composition and its cured product]

[0092] Using the obtained dispersions 1 to 5, a cured product was produced using a PTFE-containing epoxy resin composition with the compounding formulation shown in Table 2 below.

[0093] After sufficiently mixing at the compounding ratios shown in Examples 1 to 5 and Comparative Examples 1 to 3, the solvent was removed under reduced pressure at 50°C, and the pressure was further increased to 100°C. Thereafter, the reduced pressure was released, the temperature was raised to 180°C, and a cured product was obtained.

[0094] For each cured product obtained, the relative permittivity and dielectric loss tangent at 23° C. and 1 GHz were measured for motor characteristics (relative permittivity, dielectric loss tangent) using Material-analyzer 4291B (manufactured by Agilent Technologies, Inc.).

[0095] These results are shown in Table 2 below.

[00...

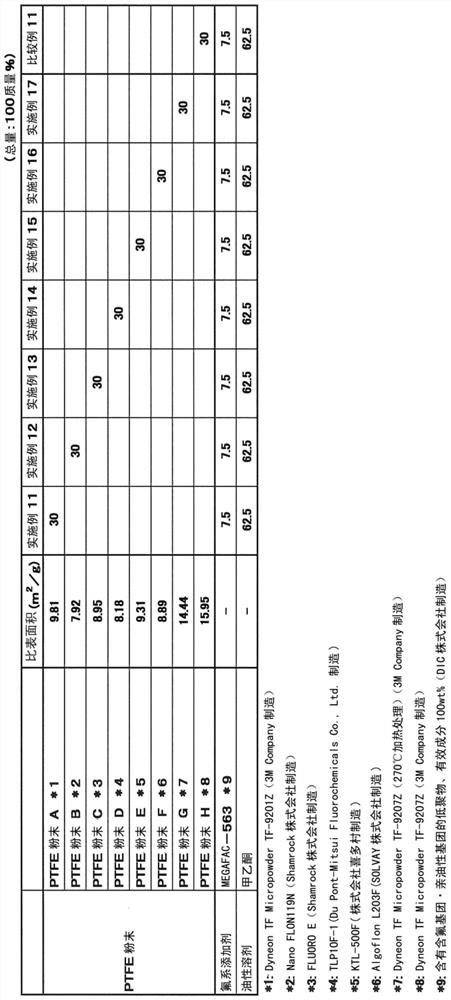

Embodiment 11~17 and comparative example 11

[0101] According to the compounding formulation shown in the following Table 3, eight types of PTFE (A to H) of each specific surface area, oligomers containing fluorine-containing groups and lipophilic groups were used as fluorine-based additives, and methyl ethyl ketone was used as an oily solvent. To prepare oily solvent dispersions of PTFE. In addition, G and H of the PTFE powder are the same, but G uses the PTFE powder which heated the PTFE powder at the temperature of 270 degreeC, changed the surface state, and adjusted the specific surface area.

[0102] In addition, in the above-mentioned preparation, the fluorine-based additive is sufficiently stirred and mixed in an oily solvent, and then PTFE is added and further stirred and mixed.

[0103] Using a horizontal bead mill, the PTFE mixture obtained above was dispersed with 0.3 mm diameter zirconia beads to obtain oily solvent dispersions of PTFE in Examples 11 to 17 and Comparative Example 11. In addition, the water c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com