Epoxy resin composition

A technology of epoxy resin and composition, applied in the field of epoxy resin composition and cured product, to achieve the effect of high flexural elastic modulus, no damage to heat resistance and excellent toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

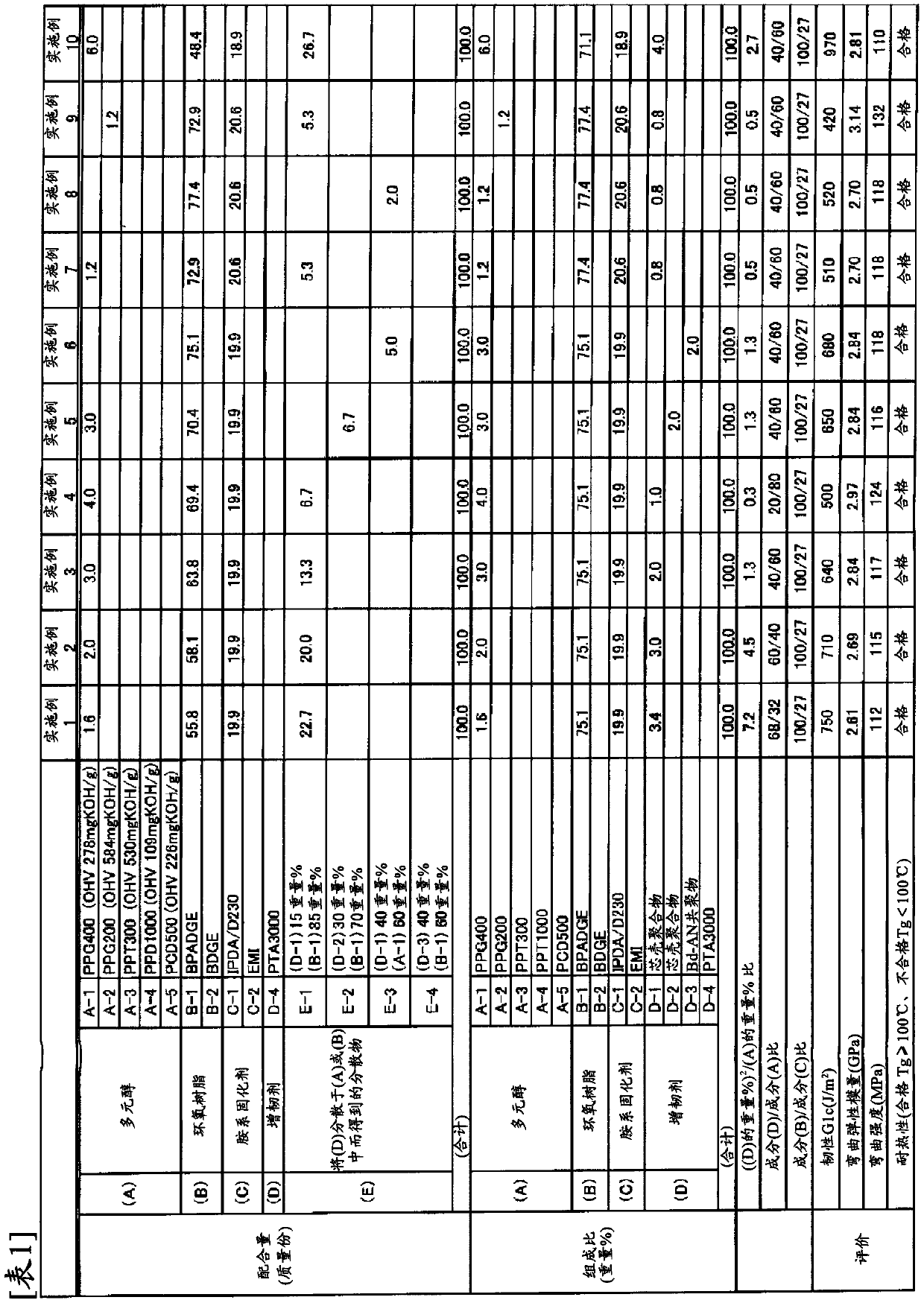

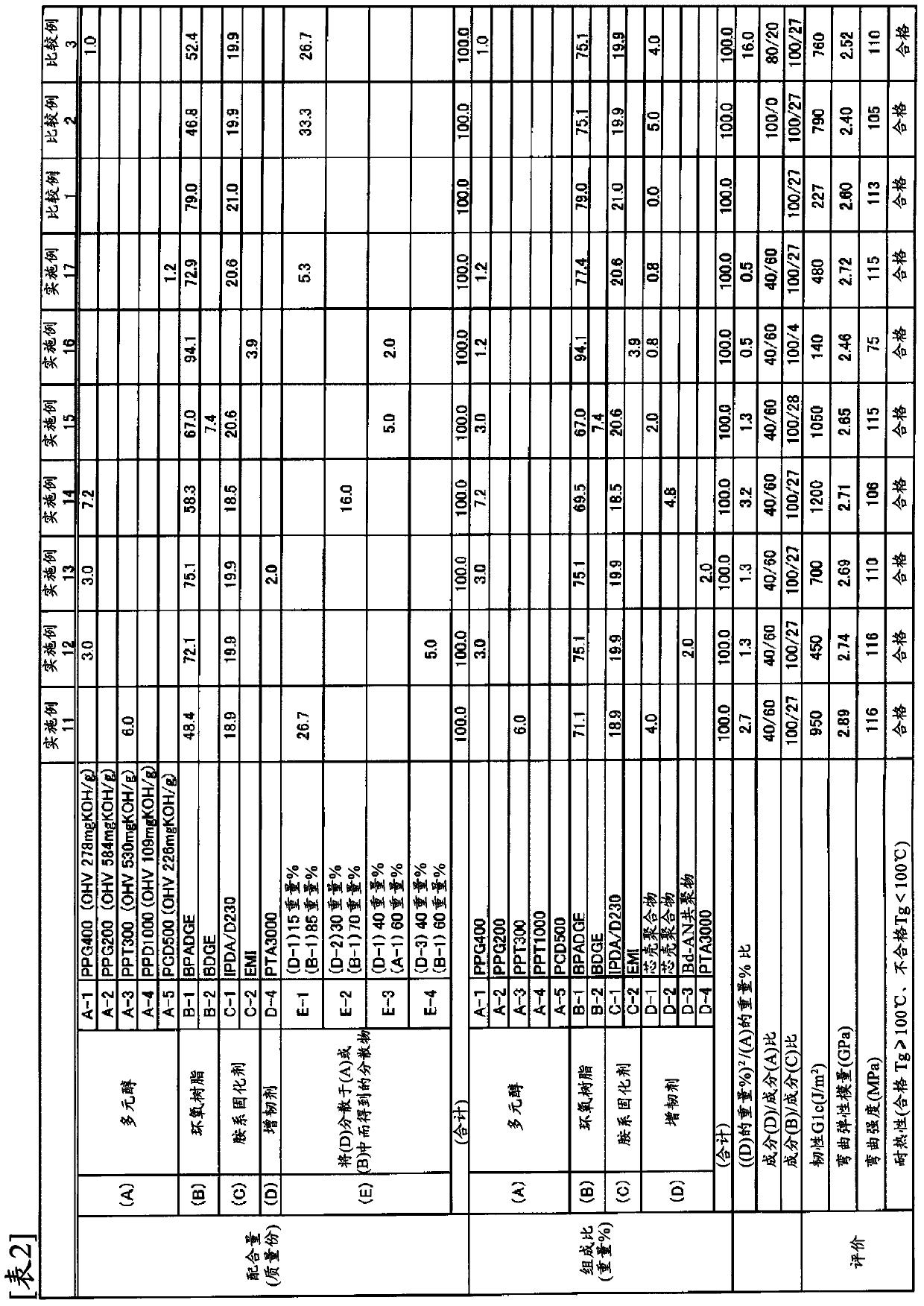

[0179] Hereinafter, the present invention will be described in more detail through examples and comparative examples, but the present invention is not limited thereto, and changes can be made appropriately within the scope of the above-mentioned / later-described gist, and these changes are all included in the technical scope of the present invention. middle. In addition, in the following Examples and comparative examples, "part" and "%" mean a weight part or weight%.

[0180] In addition, the measurement and test in the following synthesis example, the Example, and the comparative example were performed as follows.

[0181] [1] Measurement of number average particle diameter of polymer particles

[0182] The number-average particle diameter (Mn) of the polymer particles dispersed in the aqueous latex was measured using Microtrack UPA150 (manufactured by Nikkiso Co., Ltd.). A sample diluted with deionized water was used as a measurement sample.

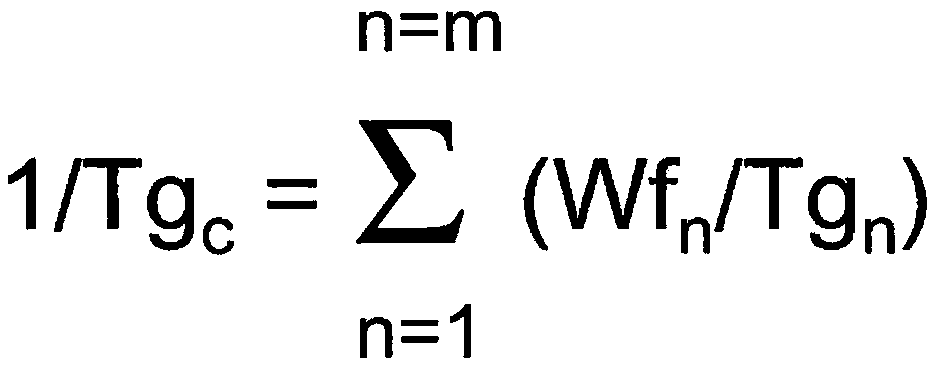

[0183] [2] Determination of M...

Synthetic example 1-1-1

[0217] Synthesis example 1-1-1; Preparation of polybutadiene rubber latex (R-1)

[0218] Put 200 parts of deionized water, 0.03 parts of tripotassium phosphate, 0.25 parts of potassium dihydrogen phosphate, 0.002 parts of disodium ethylenediaminetetraacetic acid (EDTA), and 0.001 parts of ferrous sulfate heptahydrate (Fe) into the pressure-resistant polymerizer. 2 parts and 0.2 parts of sodium dodecylbenzenesulfonate (SDS), fully replaced with nitrogen while stirring, and after removing oxygen, 100 parts of butadiene (BD) was put into the system, and the temperature was raised to 45°C. 0.015 part of hydrogen peroxide p-menthane (PHP) was added, followed by 0.04 part of sodium formaldehyde sulfoxylate (SFS), and polymerization was started. Four hours after the start of polymerization, 0.3 part of SDS, 0.01 part of PHP, 0.0015 part of EDTA and 0.001 part of Fe were added. Furthermore, 0.4 part of SDS was added in the 7th hour after polymerization. At the 10th hour of the polym...

Synthetic example 1-2-1

[0220] Synthesis example 1-2-1; Preparation of latex (D-1LX) containing core-shell polymer (D-1)

[0221] In a 5-neck glass container equipped with a reflux condenser, a nitrogen blowing port, an additional port for monomers and emulsifiers, and a thermometer, 1575 parts of latex (R-1) obtained in Synthesis Example 1-1 (equivalent to polybutylene dibutylene) was added. 518 parts of vinyl rubber particles) and 315 parts of deionized water were stirred at 60° C. while performing nitrogen replacement. After adding 0.024 parts of EDTA, 0.006 parts of Fe, and 1.2 parts of SFS, continuously add grafting monomers (57 parts of butyl acrylate (BA), 32 parts of methyl methacrylate (MMA), acrylic acid) for 2 hours. 4-hydroxybutyl ester (4-HBA) 3 parts) and the mixture of CHP 0.4 part, carry out graft polymerization. After completion of the addition, stirring was further carried out for 2 hours to complete the reaction, and latex (D-1LX) of the core-shell polymer (D-1) was obtained. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com