Release layer and release paper used for artificial leather

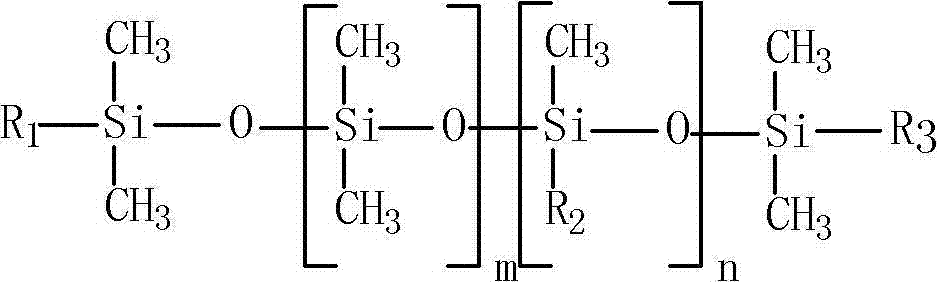

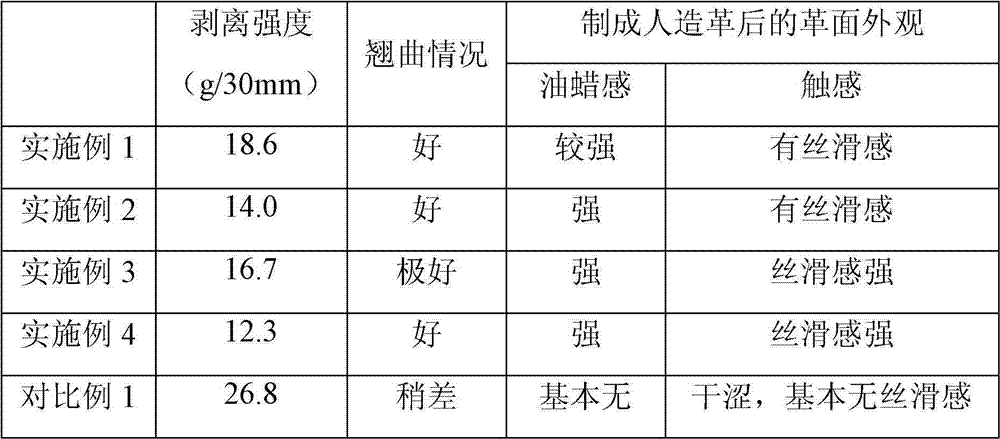

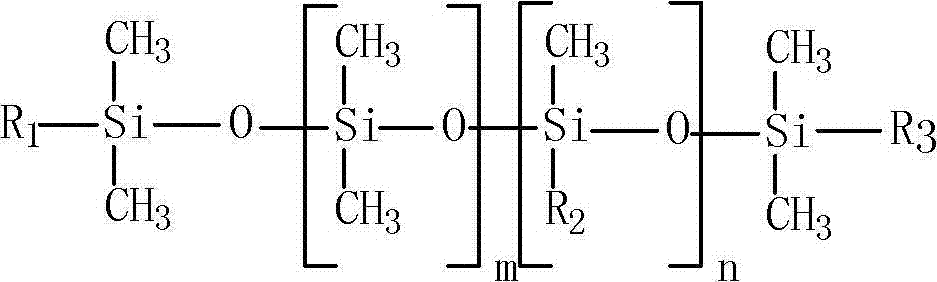

A release layer and artificial leather technology, applied in papermaking, textiles, papermaking, coating, etc., can solve the problems of reducing polyurethane film detachment, easy curling of release paper, no oily shine, etc., achieve good peelability, not easy to curl, good silky effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] In parts by weight, take 95 parts of polypropylene (melt index MFR: 28g / 10min), 5 parts of branched vinyl silicone oil (purchased from Shandong Dayi Chemical Co., Ltd., number average molecular weight: 60,000, vinyl content: 0.6 %), mix well and heat to 90°C, keep it warm for 2 hours, remove volatile components, then add 0.05 parts of dicumyl peroxide and mix well, and use extruder to coat base paper under the following extrusion coating conditions (quantitatively 128g / m 2 , corona treatment before coating) surface, while coating, embossing patterns were pressed by embossing rollers, and a release paper with a release layer thickness of 30 microns was prepared.

[0042] Extrusion coating conditions:

[0043] The temperature of each section of the extruder: C1 / C2 / C3 / C4 / XH / FP / die head are respectively

[0044] 240 / 270 / 310 / 330 / 320 / 320 / 310°C;

[0045] Mold width: 1800mm;

[0046] Extrusion speed: 80~100m / min.

Embodiment 2

[0048] In parts by weight, take 90 parts of polypropylene (MFR (melt index): 28g / 10min), 10 parts of branched vinyl silicone oil (purchased from Shandong Dayi Chemical Co., Ltd., number average molecular weight: 60,000, vinyl content is 0.6%) and mixed evenly and heated to 90 ° C, heat preservation for 2 hours, remove volatile components, then add 0.1 parts of dicumyl peroxide and mix evenly, under the extrusion coating conditions of Example 1, using extrusion Exit machine coated on base paper (quantity is 128g / m 2 , corona treatment before coating) surface, while coating, embossing patterns by embossing rollers to prepare a release paper with a release layer thickness of 35 microns.

Embodiment 3

[0050] In parts by weight, take 85 parts of polypropylene (MFR (melt index): 28g / 10min), 15 parts of branched vinyl silicone oil (purchased from Shandong Dayi Chemical Co., Ltd., number average molecular weight: 50,000, vinyl content is 0.5%) and mixed evenly and heated to 90 ° C, heat preservation for 2 hours, remove volatile components, then add 0.15 parts of dicumyl peroxide and mix evenly, under the extrusion coating conditions of Example 1, using extrusion Exit machine coated on base paper (quantity is 128g / m 2 , corona treatment before coating) surface, and embossing pattern by embossing roller while coating to prepare a release paper with a release layer thickness of 37 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com