Method for determining sulfur content in iron ore by combustion iodometry

A technology of combustion iodometric method and sulfur content, which is applied in the direction of chemical analysis by means of combustion, etc. It can solve problems such as the influence of sulfur content measurement results, the flow rate is not easy to control, and the oxygen flow rate is unstable, so as to achieve stable, accurate and reliable measurement results , Reduce energy consumption, and stabilize the airflow speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

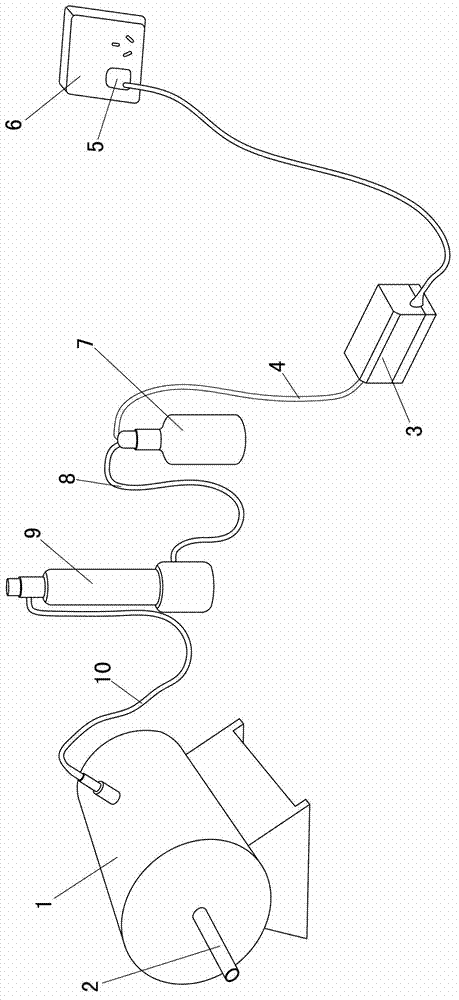

[0016] Combine figure 1 As shown, the method for determining the sulfur content in iron ore by the combustion iodometric method of the present invention is illustrated by the following examples:

[0017] (1) First, weigh 0.2000 grams of iron ore sample, place the iron ore sample in a porcelain boat, add an appropriate amount (about 1.0-1.5 grams) of copper oxide flux, and open the tube furnace 1 Rubber stopper, put the porcelain boat into the porcelain tube 2 of the tube furnace, push the porcelain boat to the high temperature part of the porcelain tube 2 with a long hook, and immediately plug the rubber stopper on the porcelain tube 2;

[0018] (2) After preheating the porcelain boat for 1.5-2 minutes, immediately turn on the switch of the micro air pump 3. In this embodiment, the micro air pump 3 uses the micro air model ACO-8500A produced by Guangdong Raoping Huanggang Xixin Power Plant The pump has a voltage of 6VDC, a power of 5W, an exhaust volume of 6L / min, a pressure of 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com