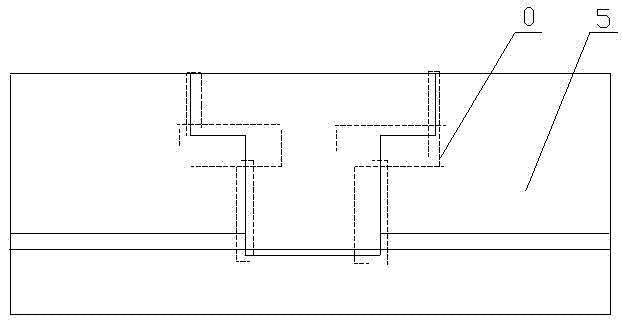

Method for copper dual damascene structure having ultralow dielectric constant layer

A technology of ultra-low dielectric constant and dielectric constant, applied in the field of microelectronics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the principle diagram and specific operation examples.

[0032] A method of copper double damascene structure with ultra-low dielectric constant layer, which includes the following steps:

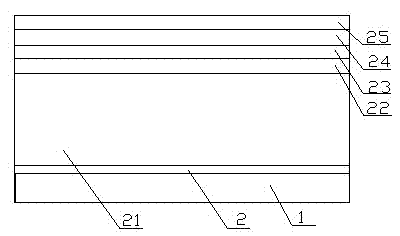

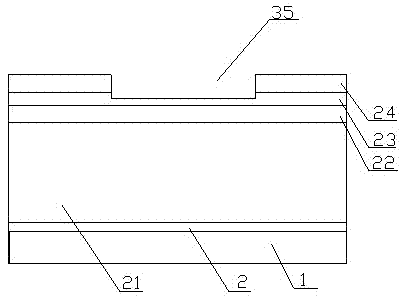

[0033] As shown in FIG. 2A, step S1: providing a substrate 1, which is a substrate with a semiconductor structure;

[0034] Step S2: deposit an etching stop layer 2 and a first interlayer dielectric layer 21 on the substrate 1 from bottom to top, the first interlayer dielectric layer 21 being a low dielectric constant layer;

[0035] Wherein, in this step, the etching stop layer 2 fabricated on the substrate 1 is an etching stop layer containing nitrogen elements, for example, it can be a silicon nitride layer or a carbon-doped silicon nitride material. .

[0036] In addition, the first interlayer dielectric layer 21 is made of a low dielectric constant material with a dielectric constant between 4 and 2.5, for example,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com