Process for the acetylation of wood elements

A technology for acetylation, wood, applied in the field of acetylation for wood parts, which can solve problems such as poor durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

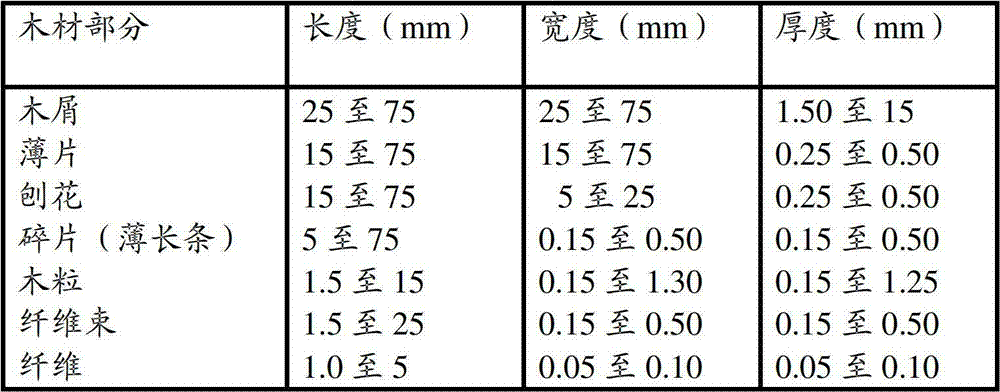

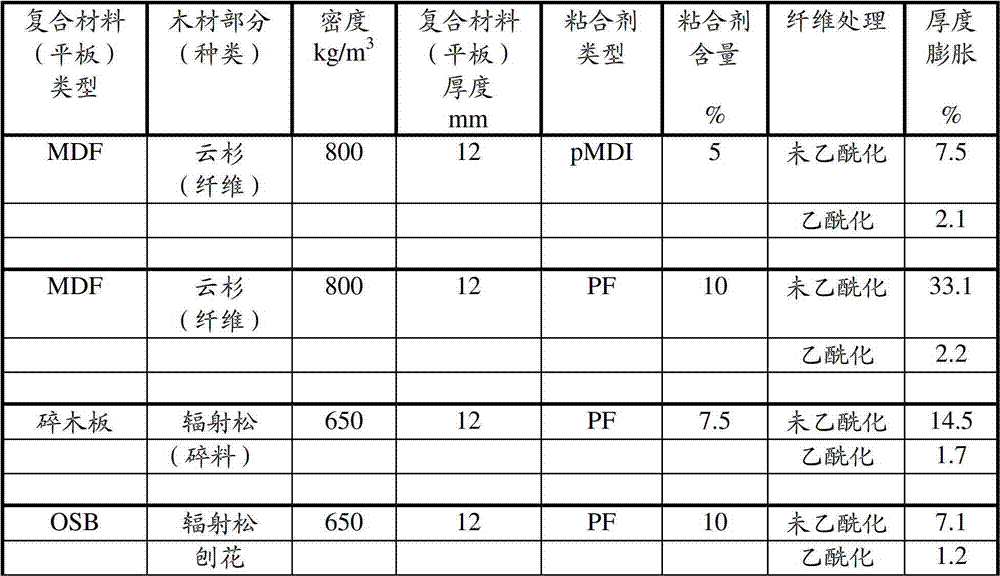

[0026] In an embodiment of the method of the invention, wood chips (approximately 40mm x 40mm x 10mm) originating from spruce and having a moisture content of 4 wt% to 10 wt% are placed in wire mesh walled baskets Medium (to allow easy passage of fluids) and placed in a pressure reactor. A vacuum of -0.95 bar was then applied to the chips for 5 minutes. Then, a preheated acetylation fluid at 130°C (comprising a mixture of 95% acetic anhydride and 5% acetic acid) was introduced into the reactor, which was subjected to a pressure of 10 bar for 10 minutes. The reactor was then drained and the wood chips were exposed to circulating nitrogen heated to 145°C for 60 minutes. During this part of the process, the pressure in the reactor may rise to 1 to 2 bar. After the pressure has been released, the acetylated wood chips are vacuum dried at -0.92 bar and cooled for 5 to 10 hours, usually 6-7 hours in total (ie drying and cooling). The level of acetylation was about 20% of the acet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com