Red mud resource utilization method

A technology for recycling and red mud, applied in the field of red mud resource utilization, can solve the problems of limited iron polymerization, low recovery rate, low value, etc., and achieve the effect of good water purification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

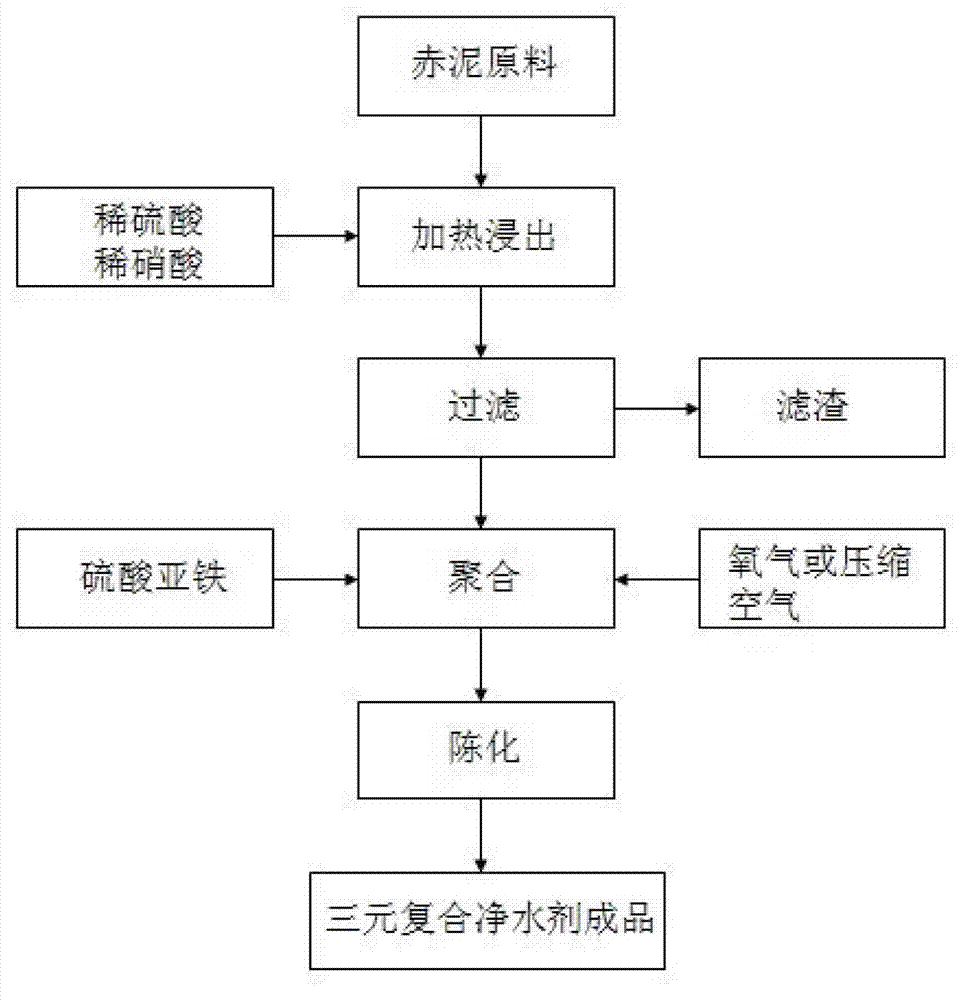

Method used

Image

Examples

Embodiment 1

[0028] Mix 1kg of red mud and 6kg of 10% dilute sulfuric acid solution, stir to form a slurry; add 60g of 10% dilute nitric acid solution, stir in the reaction kettle and heat to 40°C, leaching for 5 hours; filter, remove the filter residue, and analyze the iron in the filtrate The content of the product is 100g; add 25g of ferrous sulfate, stir and heat up to 40°C, and react with oxygen or compressed air for 10 hours; after aging for 5 hours, a silicon, iron, aluminum ternary composite water purifier is obtained, which is packaged as a finished product.

Embodiment 2

[0030] Mix 1kg of red mud and 5kg of 15% dilute sulfuric acid solution, stir to form a slurry; add 25g of 5% dilute nitrous acid solution, stir in the reaction kettle and heat to 60°C, leaching for 3 hours; filter, remove the filter residue, and analyze the filtrate The content of iron in the medium is 200g; add 2g of ferrous sulfate, stir and heat up to 60°C, and react with oxygen or compressed air for 6 hours; after aging for 20 hours, a ternary composite water purifier is obtained, which is packaged as a finished product.

Embodiment 3

[0032] Mix 1kg of red mud and 4kg of 25% dilute sulfuric acid solution, stir to form a slurry; stir in the reaction kettle and heat to 80°C, leaching for 1 hour; filter, remove the filter residue, and analyze the iron content in the filtrate to be 50g; add 8g of 35 % Potassium nitrate solution 7.5g ferrous sulfate, stirred and heated up to 80°C, reacted with oxygen or compressed air for 4 hours; after aging for 35 hours, a ternary composite water purifier was obtained, and packaged as a finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com