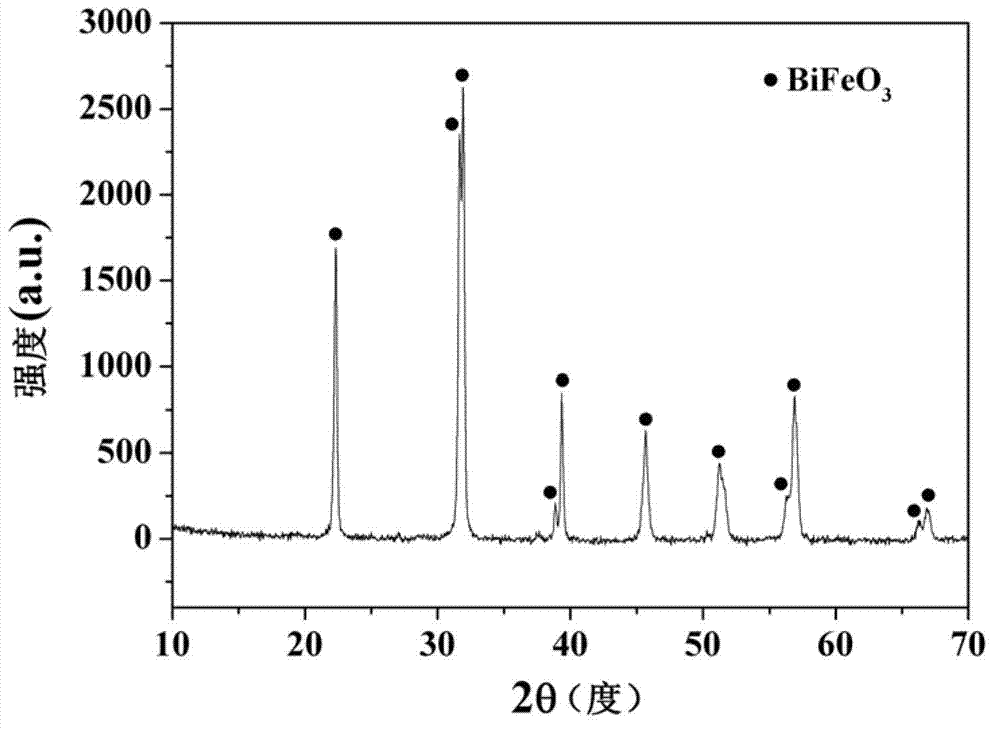

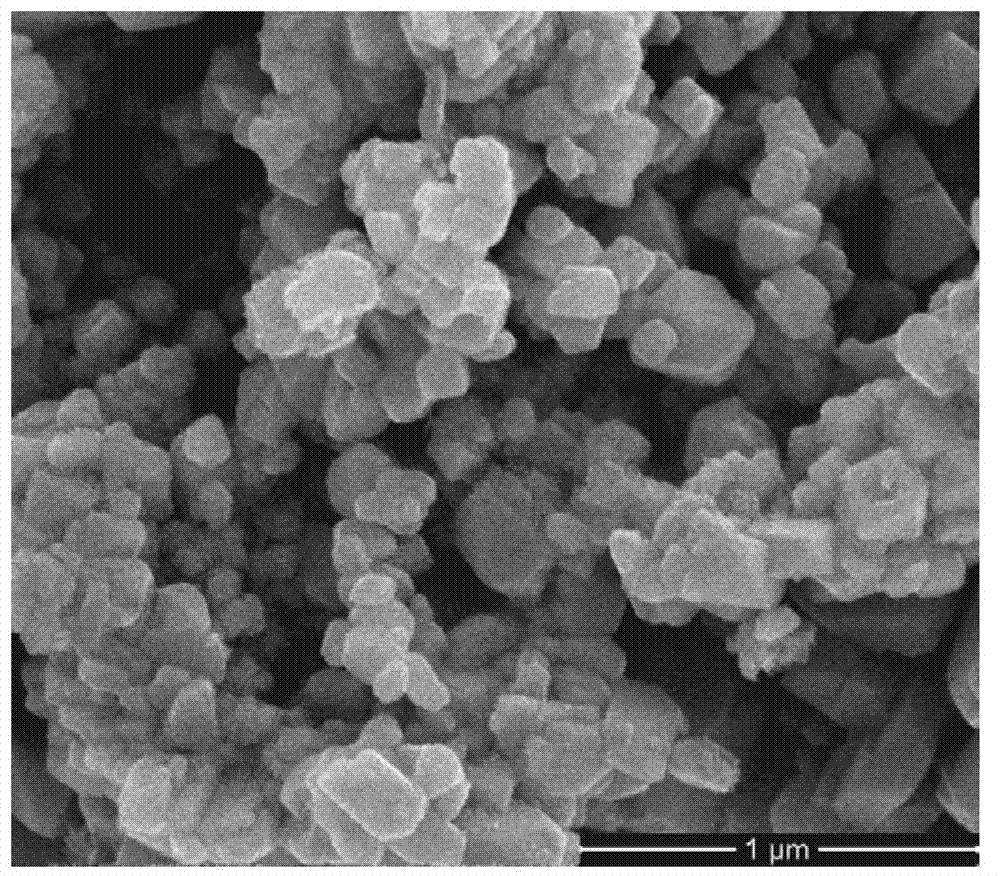

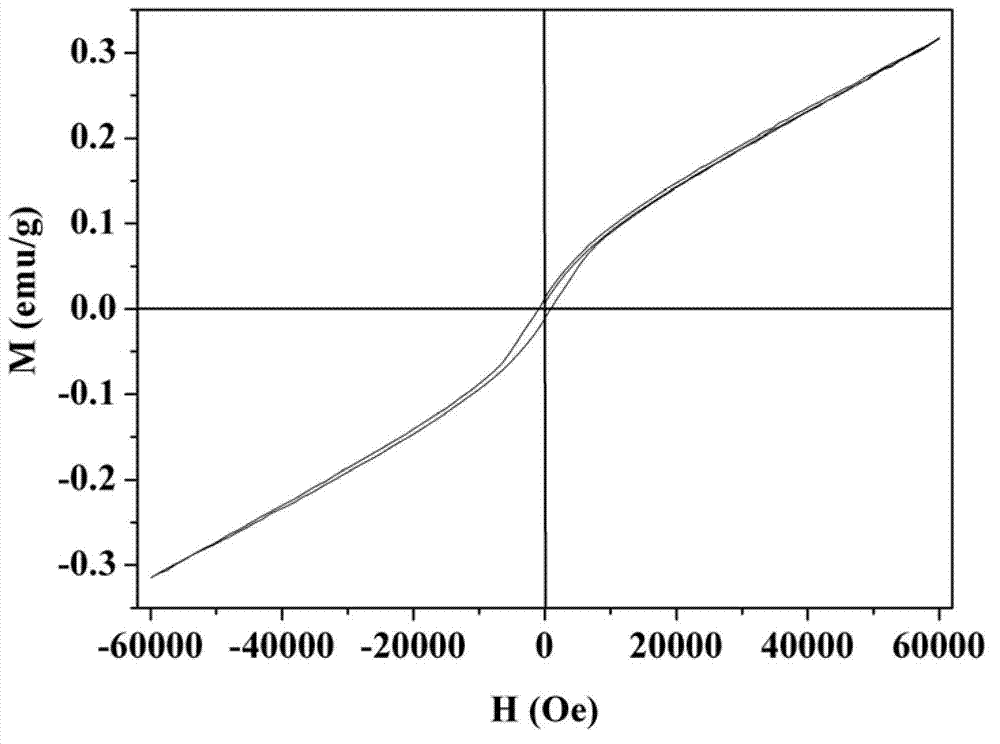

Method for preparing bismuth ferrite powder by solvothermal method

A solvothermal method, bismuth ferrite technology, applied in chemical instruments and methods, iron compounds, sustainable manufacturing/processing, etc., can solve the problem of high energy consumption, achieve the effects of simple equipment, good crystallization, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Weigh 5mmol of analytically pure Fe(NO 3 ) 3 9H 2 O and 5mmol Bi(NO 3 ) 3 ·5H 2 O, and dissolve it in 100ml of 10% nitric acid solution, and stir it magnetically for 0.5h to form a uniform mother salt solution; slowly add 40ml of 10mol / L KOH solution dropwise to the mother salt solution, and the titration speed 4.5mL / min, and magnetically stirred for 0.5h to obtain a precipitate, and then the precipitate was repeatedly washed with deionized water to neutrality, and dried in an oven at 80°C to obtain a hydrothermal reaction precursor; the hydrothermal reaction precursor Put it into a hydrothermal kettle, add a mixture of 40mL water and 30mL ethanol as a solvent, and 4mol / L KOH as a mineralizer, and the filling degree is 80%. Seal the reaction kettle, place the reaction kettle in an oven at 120°C, take out the product in the reaction kettle after reacting for 16 hours, filter the precipitate, wash it, and dry it in an oven at 80°C to obtain bismuth ferrite powder.

...

Embodiment 2

[0032] Weigh 6mmol of analytically pure Fe(NO 3 ) 3 9H 2 O and 6mmol Bi(NO 3 ) 3 ·5H 2O, and dissolve it in 100ml of 8% nitric acid solution, and stir it magnetically for 0.5h to form a uniform mother salt solution; slowly add 40ml of 8mol / L KOH solution dropwise to the mother salt solution, and the titration speed 2mL / min, and magnetically stirred for 0.5h to obtain a precipitate, and then the precipitate was repeatedly washed with deionized water to neutrality, and dried in an oven at 80°C to obtain a hydrothermal reaction precursor; the hydrothermal reaction precursor was put into Put it into a hydrothermal kettle, and add a mixture of 30mL water and 40mL ethanol as a solvent, and 10mol / L KOH as a mineralizer, and the filling degree is 75%. Seal the reaction kettle, put the reaction kettle in an oven at 130°C, take out the product in the reaction kettle after reacting for 16 hours, filter the precipitate, wash it, and dry it in an oven at 80°C to obtain bismuth ferrite...

Embodiment 3

[0034] Weigh 8mmol of analytically pure Fe(NO 3 ) 3 9H 2 O and 8mmol Bi(NO 3 ) 3 ·5H 2 O, and dissolve it in 100ml of 9% nitric acid solution, and stir it magnetically for 0.5h to form a uniform mother salt solution; slowly add 40ml of 9mol / L KOH solution dropwise to the mother salt solution, and the titration speed The temperature was 4mL / min, and magnetically stirred for 0.5h to obtain a precipitate, and then the precipitate was repeatedly washed with deionized water to neutrality, and dried in an oven at 80°C to obtain a hydrothermal reaction precursor; the hydrothermal reaction precursor was put into Put it into a hydrothermal kettle, and add a mixture of 35mL water and 35mL ethanol as a solvent, and 8mol / L KOH as a mineralizer, and the filling degree is 70%. Seal the reaction kettle, place the reaction kettle in an oven at 125°C, take out the product in the reaction kettle after reacting for 16 hours, filter the precipitate, wash it, and dry it in an oven at 80°C to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com