Sewage treatment method for nitrogen and phosphorus removal through combination of biofilm process and multilevel activated sludge process

A sewage treatment method, the technology of activated sludge method, applied in the direction of water/sludge/sewage treatment, water/sewage multi-stage treatment, chemical instruments and methods, etc., can solve the problem of poor biological nitrogen and phosphorus removal, difficult The effect of nitrogen and phosphorus removal, the mutual restriction of nitrogen and phosphorus removal effects, etc., to avoid operating management costs, promote the rate of biological nitrogen and phosphorus removal, and promote the effect of increasing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

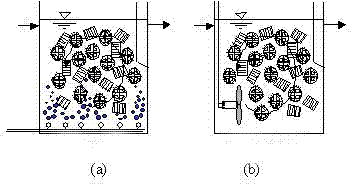

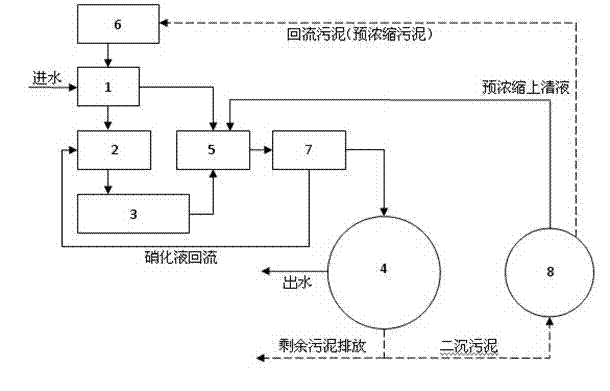

[0028] Example 1: Such as figure 1 with figure 2 As shown, the structure of this joint reaction system includes: an anaerobic tank 1, a set of first anoxic tanks 2 and a second anoxic tank 5 for carbon source diversion, an aerobic tank 3, and an MBBR tank 7, A sedimentation tank 4, a pre-concentration tank 8 for returning sludge, a pre-anoxic tank 6, and a return pipeline from MBBR tank 7 to the first anoxic tank 2, returning from the bottom of the pre-concentration tank 8 to pre-anoxic The return pipeline of the tank 6 and the return pipeline of the supernatant from the top of the pre-concentration tank 8 to the second anoxic tank 5.

[0029] In this embodiment, the sewage from the anaerobic zone is divided into two anoxic zones, forming a combined treatment unit with an aerobic tank 3 and an MBBR tank 7, which work together to remove nitrogen and phosphorus.

[0030] The method of using the above device to treat sewage is as follows:

[0031] The sewage enters the treatment syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com