Efficient sewage treatment process and device based on electron current directional adjustment and control

A technology of sewage treatment and electron flow, applied in water/sewage treatment, biological water/sewage treatment, water/sewage multi-stage treatment, etc. Reducing the concentration of difficult pollutants to achieve the effect of improving interception, high-efficiency solid-liquid separation, and enhanced removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

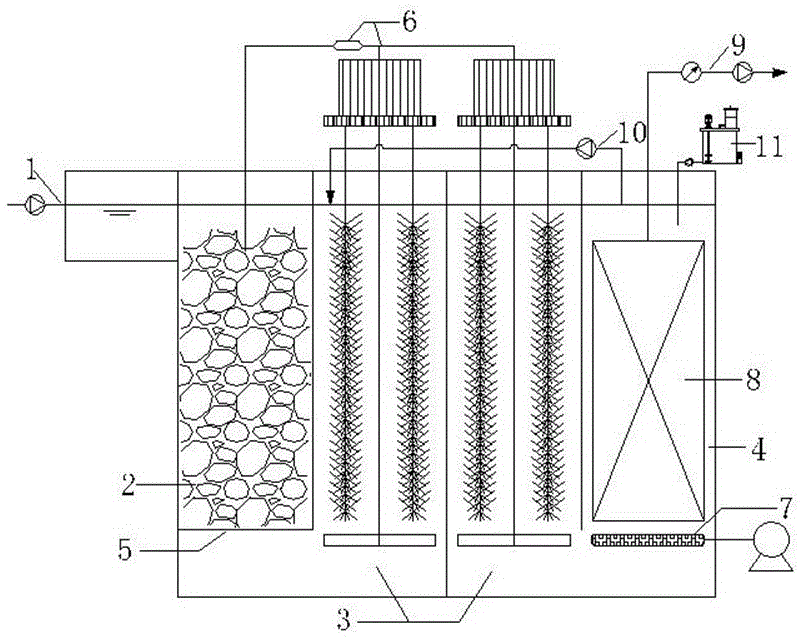

[0027] A high-efficiency sewage treatment process based on electron flow directional control, the process is carried out as follows:

[0028] 1) Sewage first enters the anaerobic fermentation electron generation chamber through the water inlet system. The granular and partially dissolved organic matter in the sewage is intercepted and adsorbed by porous conductive fillers, and the organic matter is converted into electrons under the action of electrogenic microorganisms; the treated sewage enters the heterotrophic-autotrophic denitrification chamber and the aerobic membrane separation chamber in turn .

[0029] 2) In the heterotrophic-autotrophic denitrification chamber, the microorganisms use the residual organic matter in the feed water and the electrons transferred from the external circuit, and through the heterotrophic and autotrophic denitrification pathways, the sludge mixture returned from the aerobic membrane separation chamber Nitrate or nitrite in the removal.

[...

Embodiment 2

[0034] Using the process and device described in Example 1 to treat rural domestic sewage, the influent COD concentration is 312.7±20.9mg / L, the ammonia nitrogen concentration is 27.7±5.8mg / L, the total nitrogen concentration is 30.3±7.8mg / L, and the total phosphorus concentration 8.1±3.2mg / L. The hydraulic retention time is 13.7h, and the membrane flux is 22L / (m 2 · h), the dosage of chemical agent polyferric chloride is 12mg / L. The average removal rate of COD was (96.3±1.0)%, the average removal rate of ammonia nitrogen was (99.2±0.9)%, the average removal rate of total nitrogen was (92.2±2.4)%, and the average removal rate of total phosphorus was (87.1±4.2)%. The membrane cleaning cycle is maintained at more than 150d, and the maximum power density can reach 94.2mW / m 2 .

Embodiment 3

[0036] Using the process and device described in Example 1 to treat actual domestic sewage in a community, the influent COD concentration is 320.7±70.6mg / L, ammonia nitrogen concentration is 46.1±7.2mg / L, and total nitrogen concentration is 55.6±8.2mg / L. The hydraulic retention time is 14h, and the membrane flux is 18L / (m 2 h). The average removal rate of COD is (96.9±2.4)%, the average removal rate of ammonia nitrogen is (98.5±1.2)%, the average removal rate of total nitrogen is (84.7±3.5)%, the membrane cleaning cycle is maintained at more than 150d, and the maximum power density can Reached 91.9mW / m 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com