Quartz ceramic crucible for producing high-efficiency polycrystals and preparation method thereof

A technology of quartz ceramics and crucibles, which is applied in glass production, glass manufacturing equipment, chemical instruments and methods, etc., can solve problems such as defects, reduce high aluminum content, and poor thermal performance of crucibles, so as to improve thermal performance and reduce aluminum content, the effect of reducing the content of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0027] Put 1 part of ultrafine quartz powder less than 1 micron with a purity of 99.991%, 3 parts of quartz powder from 1 micron to 200 microns, and 1 part of quartz aggregate from 200 microns to 1000 microns into a high-shear mixer Mix well, then add 6 parts water and mix for 1 hour. The inner surface of the quartz ceramic crucible was coated by dip coating, and after dip coating, the crucible was put into a drying oven and dried at 80° C. for 5 hours to obtain a quartz ceramic crucible for producing high-efficiency polycrystals.

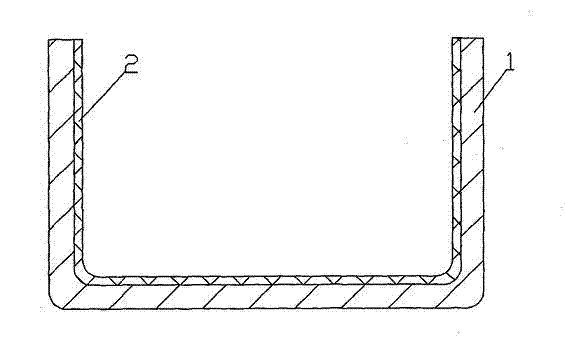

[0028] get as figure 1 The shown quartz ceramic crucible for producing high-efficiency polycrystals includes a crucible body. The crucible body is an opaque quartz ceramic crucible. The inner surface of the crucible body contains a high-purity quartz ceramic inner layer with a thickness of 800 microns.

specific Embodiment 2

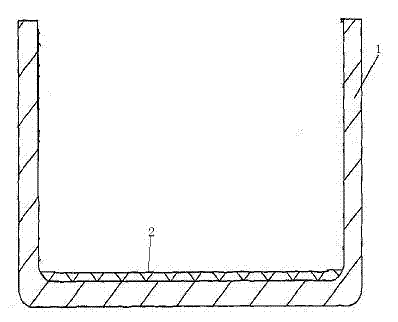

[0029] Put 2 parts of ultrafine quartz powder less than 1 micron with a purity of 99.993%, 1 part of quartz powder from 1 micron to 200 microns, and 1 part of quartz aggregate from 200 microns to 1000 microns into a high-shear mixer Mix well, then add 6 parts of water and mix for 0.5 hours. Spraying is carried out on the inner surface of the quartz ceramic crucible by means of spraying. After spraying, the crucible is placed in a drying oven and dried at 150° C. for 2 hours to obtain a quartz ceramic crucible for producing high-efficiency polycrystalline. like figure 2 The shown quartz ceramic crucible for producing high-efficiency polycrystals includes a crucible body, the crucible body is an opaque quartz ceramic crucible, and contains a high-purity quartz ceramic inner layer at the bottom of the inner surface of the crucible body, and the thickness of the inner layer is 10 microns.

specific Embodiment 3

[0030] Put 4 parts of 200 micron-1000 micron quartz material with a purity of 99.99% into a wet ball mill, add 3 parts of water, ball mill for 8 hours, and the particle size of the slurry reaches 0.8-50 microns. Then add 1 part of 200 micron-1000 micron aggregate, mix for 1 hour, then put 1 part of 200 micron-1000 micron quartz aggregate with a purity of 99.99% into a high-shear mixer and mix evenly, and then put it into 6 part water, mix for 1.5 hours. The inner surface of the quartz ceramic crucible was coated by brushing. After brushing, the crucible was put into a drying oven and dried at 80° C. for 5 hours to obtain a quartz ceramic crucible for producing high-efficiency polycrystalline.

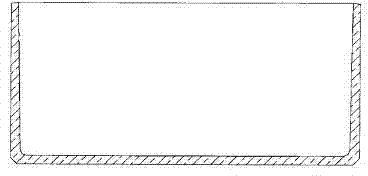

[0031] The quartz ceramic crucible for producing high-efficiency polycrystalline, including a crucible body, the crucible body is an opaque quartz ceramic crucible, the inner surface of the crucible body contains a high-purity quartz ceramic inner layer, and the thickness of the inner l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com