Preparation method of natural benzaldehyde

A benzaldehyde, natural technology, applied in the field of preparation of natural benzaldehyde, can solve the problem of low ozone utilization rate, achieve high ozone utilization rate, good reaction rate, high purity and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

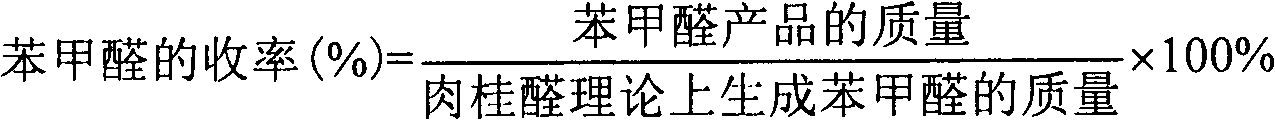

Embodiment 1

[0025] In the bubbling reactor, add 5.26g cinnamaldehyde (more than 95% of cinnamaldehyde content), 10.00g dehydrated alcohol, 0.25g TiO 2 Catalyst, pass ozone into the bubbling reactor at a flow rate of 0.1g (ozone) / g (cinnamaldehyde) / h, and perform an ozonation reaction at 0° C. for 2 hours to obtain an ozonide intermediate. Then dissolve 3.00g of thiourea and 0.21g of oxalic acid in 30mL of deionized water, slowly drop the ozonated intermediate into the aqueous solution of thiourea, perform a reduction reaction at 0°C for 2 hours, separate oil from water, Molecular distillation was carried out under the following conditions, and the available benzaldehyde product was 1.85g, and the yield of benzaldehyde was 46.1%.

Embodiment 2

[0027] In the bubbling reactor, add 5.31g cinnamaldehyde (more than 95% of cinnamaldehyde content), 10.1g dehydrated alcohol, 0.50g gac respectively, by 0.1g (ozone) / g (cinnamaldehyde) / h flow rate, ozone is passed into In the bubbling reactor, the ozonation reaction was carried out at 5° C. for 2 h to obtain the ozonide intermediate. Then dissolve 3.10g of thiourea and 0.19g of oxalic acid in 30mL of deionized water, slowly drop the ozonated intermediate into the aqueous solution of thiourea, perform a reduction reaction at 0°C for 2 hours, separate oil from water, Molecular distillation was carried out under the following conditions, and the benzaldehyde product was 1.59g, and the yield of benzaldehyde was 39.3%.

Embodiment 3

[0029] In the bubbling reactor, add respectively 5.28g cinnamaldehyde (more than 95% of cinnamaldehyde content), 10.03g dehydrated alcohol, 0.25g MnO 2 Catalyst, pass ozone into the bubbling reactor at a flow rate of 0.1g (ozone) / g (cinnamaldehyde) / h, and perform an ozonation reaction at 0° C. for 2 hours to obtain an ozonide intermediate. Then dissolve 2.99g of thiourea and 0.22g of oxalic acid in 30mL of deionized water, slowly drop the ozonated intermediate into the aqueous solution of thiourea, perform a reduction reaction at 0°C for 2 hours, separate oil from water, Molecular distillation was carried out under the following conditions, and the benzaldehyde product was 2.04g, and the yield of benzaldehyde was 50.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com