Biological latex, preparation method and application thereof

A technology of biological latex and mixed latex, which is applied in coatings, paper coatings, textiles and papermaking, etc., can solve the problems of being easily affected by the oil market, increasing the production cost of coated paper, and high prices, so as to achieve rich and cheap raw materials, reduce production costs and The effect of controlling production cost and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0011] The preparation method of biological latex among the present invention is as follows:

[0012] (1) Prepare plant starch into starch slurry. The starch can be one of plant starches such as corn, potato and cassava, or any mixture thereof. The mass concentration of the starch slurry is 35-40%.

[0013] (2) Add a graft modifier of 1-20% of the starch mass and an initiator of 0.1-1% of the starch mass, and react for 3-5 hours at 30-50°C, wherein the graft modifier is propylene One of amides, acrylonitrile, methacrylamide, N-methacrylamide, N.N-dimethylacrylamide or any mixture thereof, the initiator is potassium permanganate;

[0014] (3) adding an oxidizing agent of 10-30% of the starch mass to carry out a trace oxidation reaction, wherein the oxidizing agent can be sodium hypochlorite or hydrogen peroxide;

[0015] (4) Dilute the starch slurry to a mass concentration of 6-10%

[0016] (5) drying and gelatinizing the mixed emulsion to obtain biological latex. Wherein ...

Embodiment 1

[0019] Embodiment 1: Under the protection of nitrogen, add 140g of absolute dry raw cassava starch in the reaction kettle, add water to 400g to prepare a starch slurry with a mass concentration of 35%, keep the temperature at 40°C, add 14g of acrylonitrile and 0.2 g potassium permanganate, reacted for 4 hours, in order to speed up the reaction rate, it can also be reacted under electric agitator stirring, then add 14g of hydrogen peroxide and dilute the starch slurry to 8% mass concentration, and use the roller gelatinization film-forming method to gelatinize , use a metering rod to apply the reacted starch slurry on a drum or drying cylinder, the gelatinization temperature is 90 degrees Celsius, and then scrape off the film and grind it into a fine powder to obtain bio-latex.

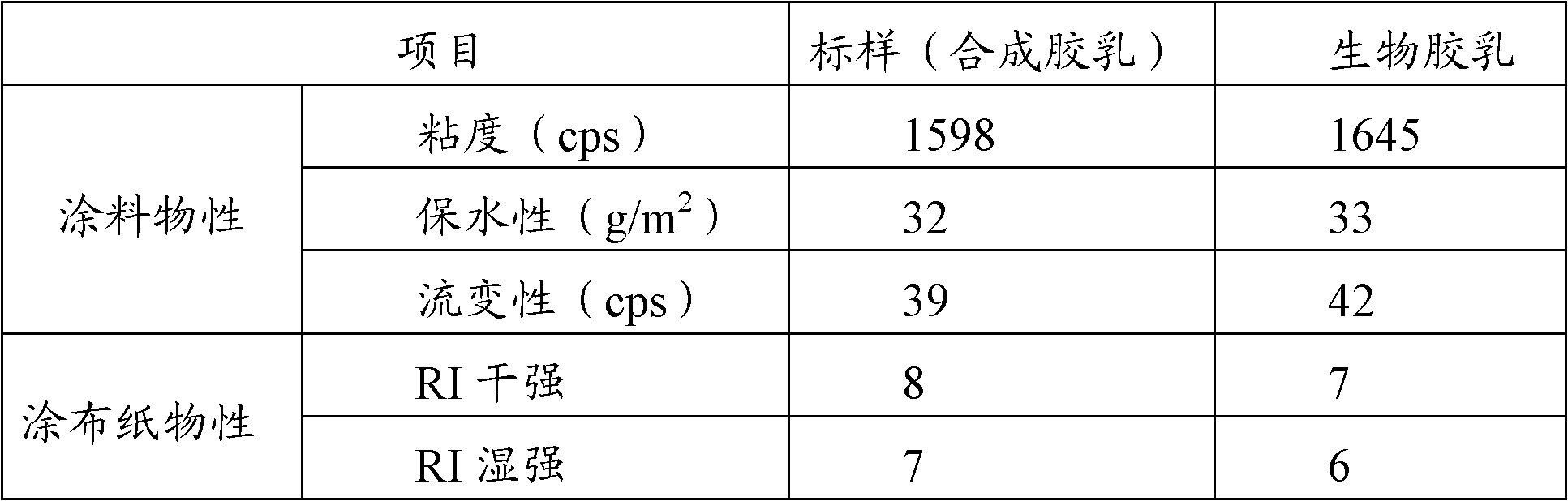

[0020] Using 50% of biological latex instead of synthetic latex to prepare paint, the application effect is shown in the table below:

[0021]

Embodiment 2

[0022] Embodiment 2: Under the protection of nitrogen, add 160g of absolute dry raw cassava starch in the reaction kettle, add water to 400g to prepare a starch slurry with a mass concentration of 40%, keep the temperature at 40°C, add 20g of acrylamide and 0.3 g potassium permanganate, reacted for 4 hours, in order to speed up the reaction rate, it can also be reacted under electric agitator stirring, then add 25g of sodium hypochlorite and dilute the starch slurry to 8% mass concentration, and use the roller gelatinization film-forming method to gelatinize , use a metering rod to apply the reacted starch slurry on a drum or drying cylinder, the gelatinization temperature is 95 degrees Celsius, scrape off the film and grind it into a fine powder to obtain bio-latex.

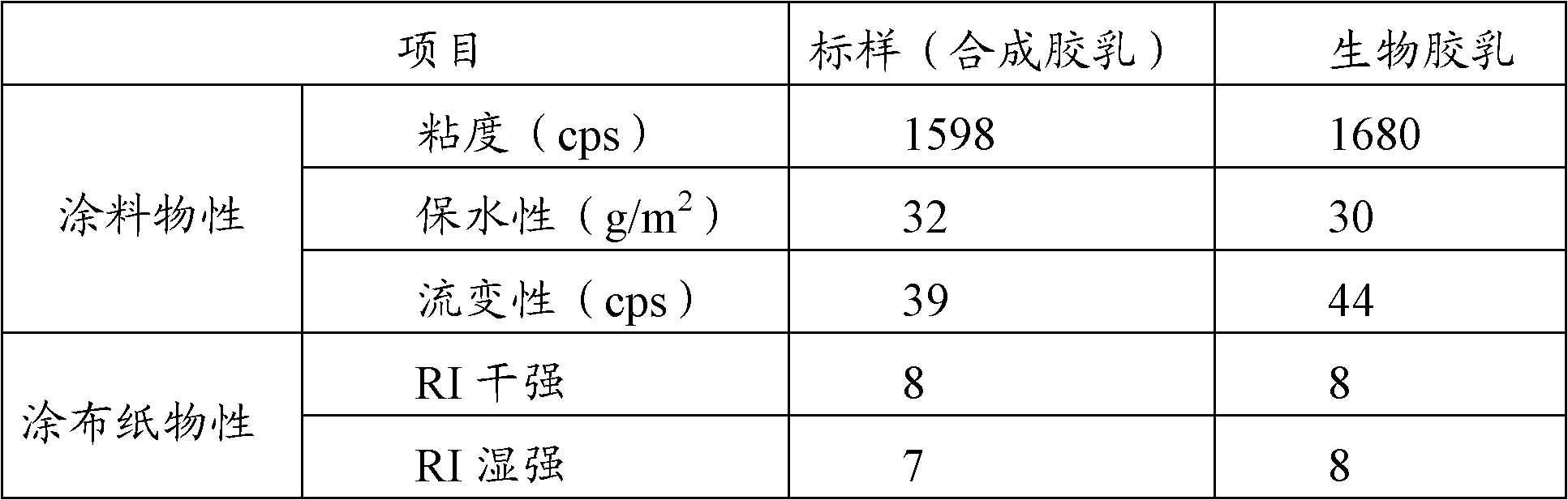

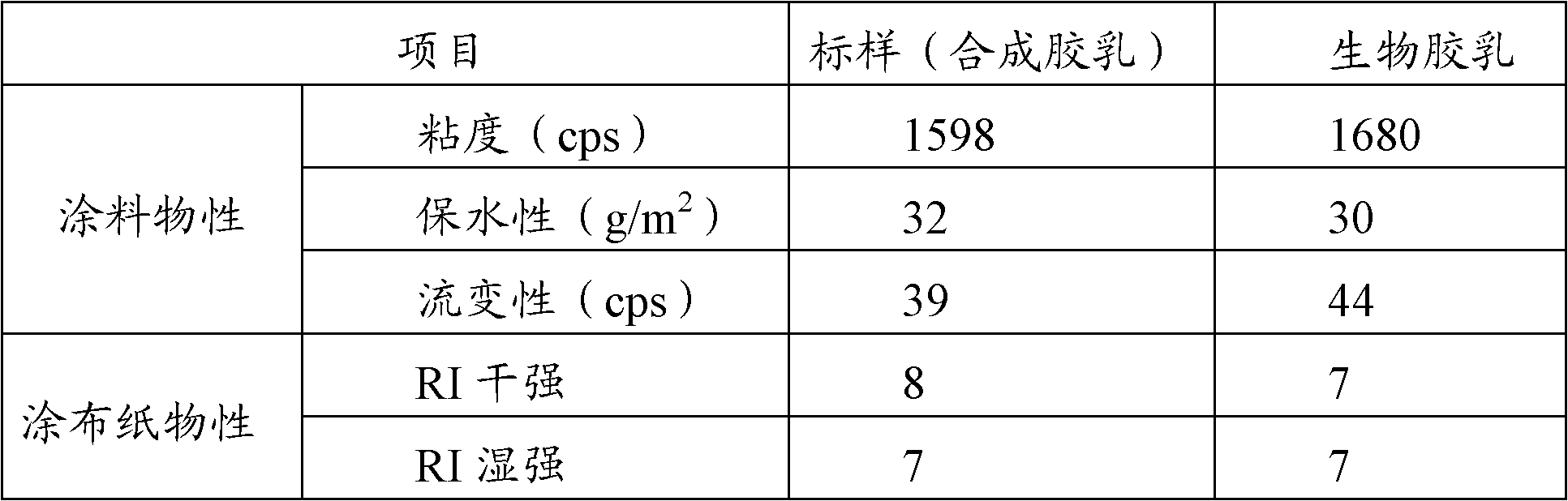

[0023] Using 50% of biological latex instead of synthetic latex to prepare paint, the application effect is shown in the table below:

[0024]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com