Water-soluble silicone-modified polyester resin composition and preparation method thereof

A polyester resin, silicone technology, applied in the coating and other directions, can solve the problems of heat resistance and poor film hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

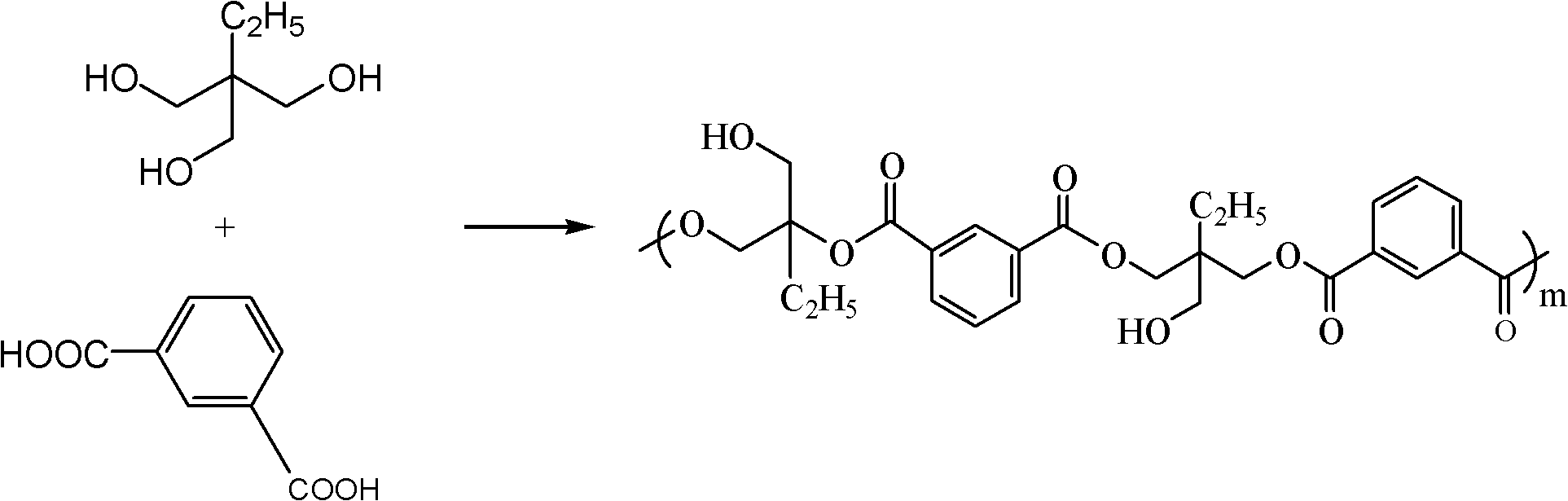

[0034] Step 1 (synthesis of polyester polyol resin)

[0035] Get the trimethylolpropane of 1275 parts by weight, the neopentyl glycol of 156 parts by weight and the isophthalic acid of 1304 parts by weight add to have nitrogen, in the 5 liters reaction tanks of condensing tube heating and mechanical stirring device, the temperature Control it at 200°C-240°C, after 282.8 parts by weight of water are desorbed and the acid value is controlled below 10, when the temperature is lowered to 180°C, add 818 parts by weight of γ-butyl lactone to dissolve the polyester polyol .

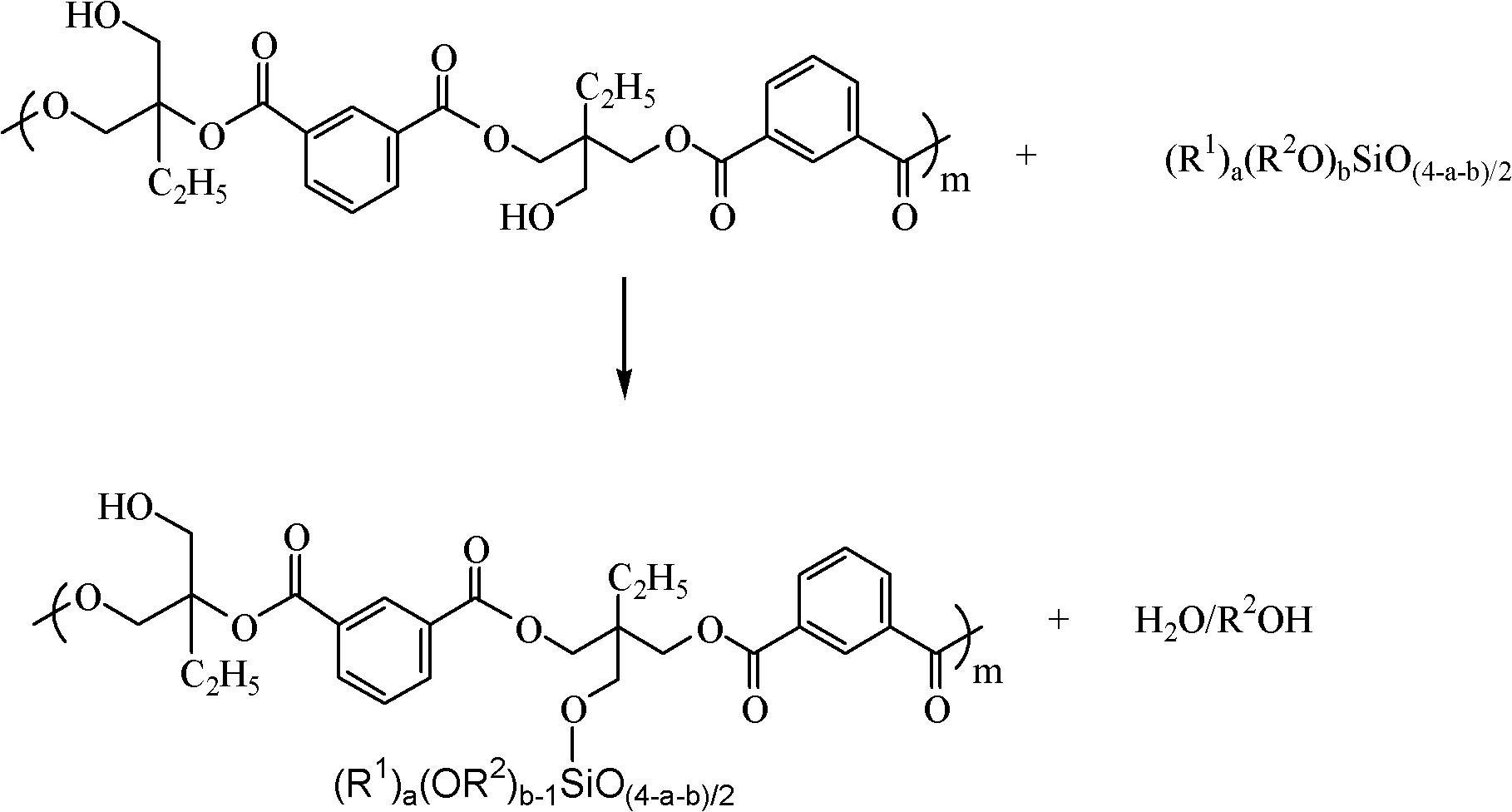

[0036] Step 2 (synthesis of silicone modified polyester resin)

[0037] Get 400 parts by weight of polyester polyol synthesized in step 1, 128.5 parts by weight of silicone resin (Silres H44 purchased from Wacker), 0.8 parts by weight of tetraisopropyl titanate, and 73 parts by weight of γ -Butyl lactone, added to a 2-liter reaction tank with a nitrogen device condensing tube, a heating device and a mechanical...

Embodiment 2

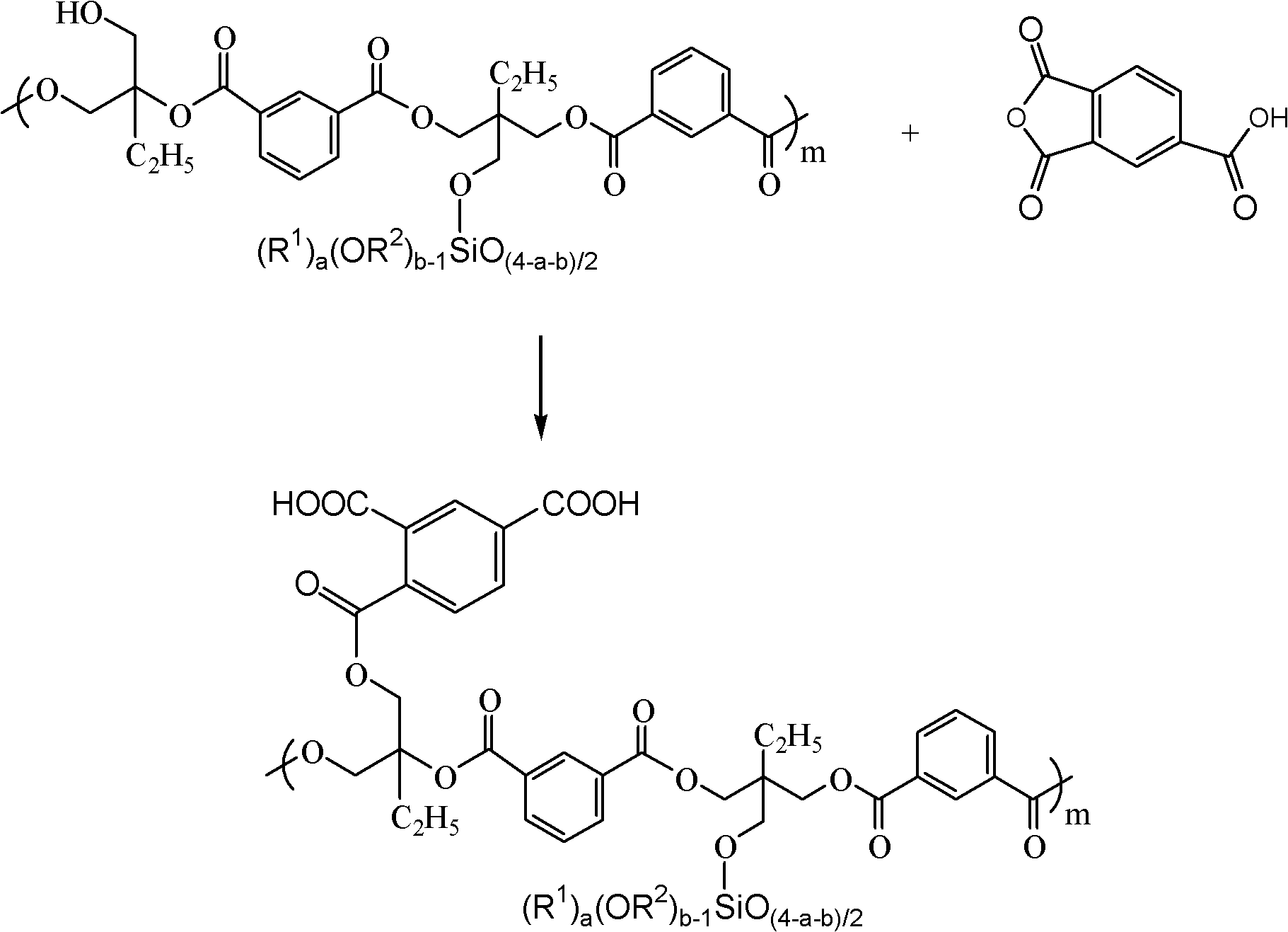

[0046] Get 400 parts by weight of polyester polyol synthesized in Step 1 of Implementation 1, 128.5 parts by weight of silicone resin (available from Silres H44 from Wacker), 0.8 parts by weight of tetraisopropyl titanate, and 73 parts by weight of γ-butyl lactone is added to a 2-liter reaction tank with a nitrogen device condensing tube, a heating device, and a mechanical stirring device, and the temperature is controlled at 130-140 ° C. After the reaction is cooled to 95 ° C for 4 hours , add 80 parts by weight of phthalic anhydride (see formula 6), maintain the temperature at 95-100 ° C, stir for 2 hours, then the acid value is 80, then add 73 parts by weight of diethylene glycol monobutyl ether. Add 64 parts by weight of dimethylethanolamine and 7.0 parts by weight of ammonia water (25%) at room temperature, stir for 30 minutes, and then add 256 parts by weight of pure water to obtain a transparent and viscous water-soluble silicone modified polyester. The viscosity at 25...

Embodiment 3

[0051] Get 400 parts by weight of polyester polyols synthesized in Step 1 of Implementation 1, 125.8 parts by weight of silicone resin (available from Wacker's Silres REN 168), 0.8 parts by weight of tetraisopropyl titanate, and 73 parts by weight of γ-Butyl lactone is added to a 2-liter reaction tank with a nitrogen device, a condenser, a heating device, and a mechanical stirring device. The temperature is controlled at 130-140 ° C. After the reaction is cooled to 95 ° C for 3 hours, 108 3,3',4,4'biphenyltetracarboxylic dianhydride (see formula 7), the temperature was maintained at 110°C, and after stirring for 1 hour, the acid value was 58, and then 60 parts by weight of n-butyl alcohol. At 40°C, add 45 parts by weight of dimethylethanolamine and 8.5 parts by weight of ammonia water (25%), stir for 30 minutes, and then add 470 parts by weight of pure water to obtain a transparent and viscous water-soluble silicone modified polymer. The ester has a viscosity of 7000cps at 25...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com