Fluoride fluorescent powder material and semiconductor light-emitting device thereof

A technology of light-emitting devices and phosphors, which is applied in the field of phosphor materials and can solve problems such as material shortage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

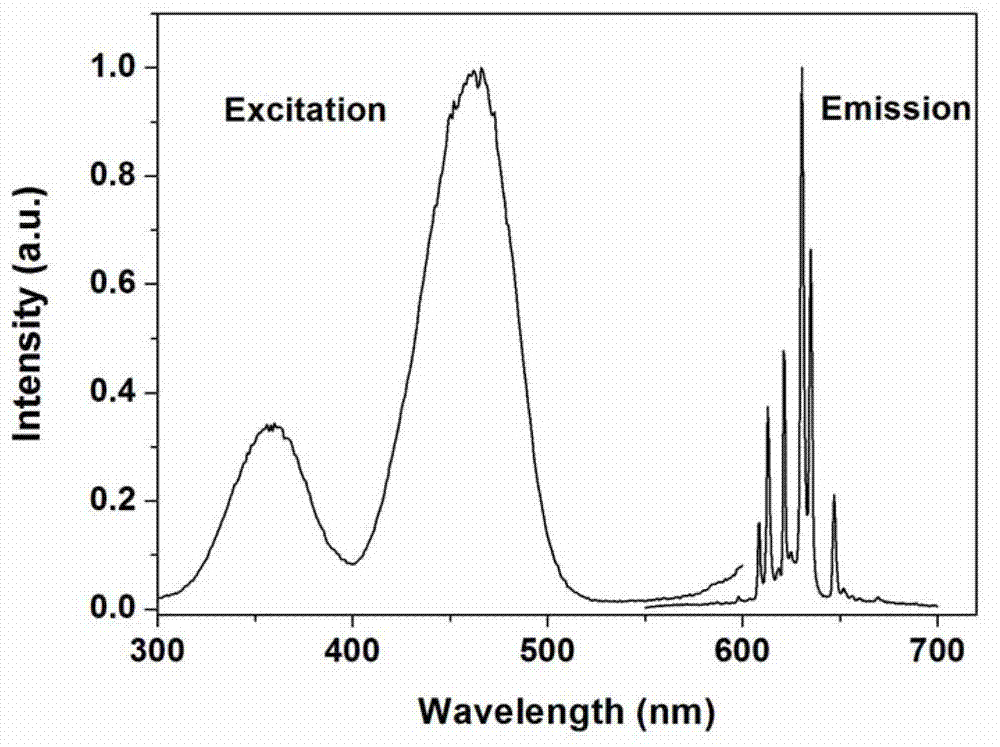

[0022] Embodiment 1, ACaAlF 6 :Mn 4+ (A=Li, Na, K, Rb, Cs) Phosphor Powder Preparation

[0023] 1.2843 g AlCl 3 ·6H 2 O and stoichiometric CaCl 2 , alkali metal chlorides (LiCl 3H2 O, NaCl, KCl, RbCl and CsCl) were added to 20 ml of hydrofluoric acid (50%), stirred at room temperature for 1 hour, then centrifuged to separate the precipitate, and the obtained product was washed with 20 ml of acetone and dried at 90 degrees Celsius Dry to get ACaAlF 6 . 10 grams of samples were obtained through multiple preparations.

[0024] Combine the product obtained above with a certain amount of K 2 MnF 6 Mix evenly, add appropriate amount of hydrofluoric acid and stir, and dry the obtained product at 90 degrees Celsius to obtain ACaAlF 6 :Mn 4+ (A=Li, Na, K, Rb, Cs) phosphor. Synthesis of Medium Matrix Crystal ACaAlF 6 The ratio of raw materials is shown in Table 1, Mn 4+ The doped materials are prepared according to the molar ratios of Mn and Al being 0.1:9.9, 1:9 and 2:8 re...

Embodiment 2

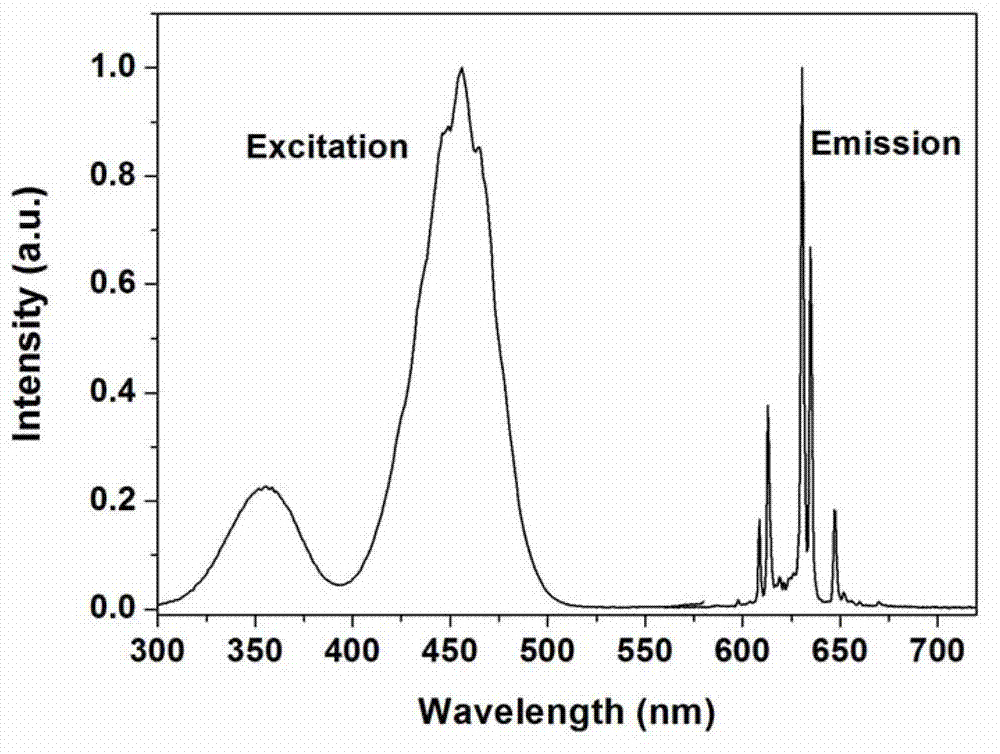

[0029] Example 2, ACa(Ga, In)F 6 :Mn 4+ (A=Li, Na, K, Rb, Cs) Phosphor Powder Preparation

[0030] The stoichiometric ratio of AF, MF 2 , GaF 3 and InF 3 Mix well, then heat to a certain temperature in an atmosphere of hydrogen fluoride gas (purity 99.9%) and keep the temperature constant for a period of time, then cool naturally to obtain AM(Ga,In)F 6 powder sample.

[0031] Combine the product obtained above with a certain amount of K 2 MnF 6 Mix evenly, add appropriate amount of hydrofluoric acid and stir, and dry the product at 90 degrees Celsius to obtain AM(Ga,In)F 6 :Mn 4+ Phosphor. Synthesis of host crystal ACaAlF 6 The raw material distribution and process conditions such as shown in Table 3, Mn 4+ The doped materials were synthesized according to the molar ratios of Mn and the sum of Ga and In in the matrix crystals being 0.1:9.9, 1:9 and 2:8, respectively, and the ratio of 2:8 was shown in Table 4.

[0032] Table 3 ACa(Ga,In)F 6 Raw material ratio for m...

Embodiment 3

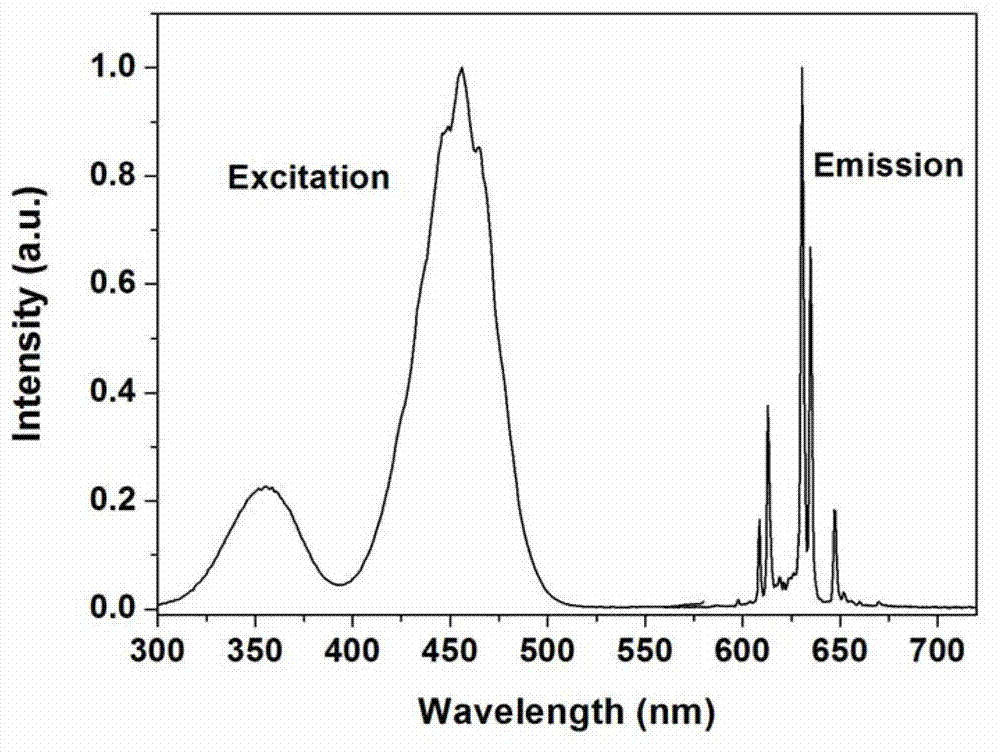

[0036] Embodiment 3, MAIF 5 :Mn 4+ (M = Mg, Zn, Ba, Sr, Ca) Phosphor Powder Preparation

[0037] 0.7243 g AlCl 3 ·6H 2 O and the stoichiometric corresponding chloride (MgCl 2 ·6H 2 O, ZnCl 2 , BaCl 2 , CaCl 2 and SrCl 2 ) into 10 ml of distilled water, stirred for 30 minutes until completely dissolved, then added 5ml of hydrofluoric acid (40%), and volatilized in an 80-degree water bath while stirring to obtain MAlF 5 product. 10 grams of samples were obtained through multiple preparations.

[0038] Combine the above product with a certain amount of K 2 MnF 6 Mix evenly, and stir after adding an appropriate amount of hydrofluoric acid, and the obtained product can be dried at 90 degrees Celsius to obtain MAIF 5 :Mn 4+ (M = Mg, Zn, Ba, Sr, Ca) phosphor. Synthesis of Matrix Crystal MAlF 5 The ratio of raw materials is shown in Table 5, Mn 4+ The synthesis of doped materials is prepared according to the molar ratios of Mn and Al of 0.1:9.9, 1:9 and 2:8, respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com