Method for detecting quality of tobacco flavor

A technology of tobacco flavor and detection method, which is applied in the directions of measuring devices, instruments, scientific instruments, etc., can solve the problems of low accuracy of results and limited application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

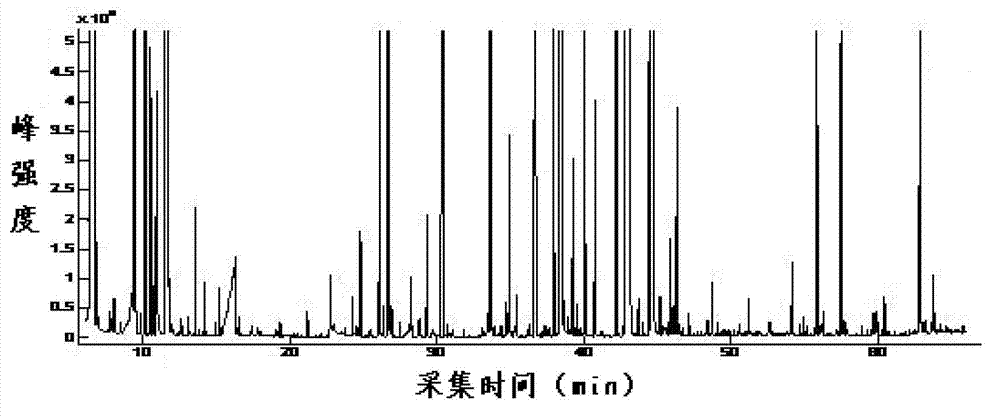

[0104] Use a pipette gun to pipette 400 μL of tobacco flavor samples D, E, F, G, J, K, L and N into 4 mL sample bottles, add 800 μL of dichloromethane to it, shake well and place on a rotary shaker Shake it up for 10 minutes, let it stand for 10 minutes, remove the lower organic layer, then add 1 g of anhydrous sodium sulfate to the obtained lower organic layer, dry it at room temperature for 30 minutes, and perform GC / MS analysis.

[0105] GC / MS analysis conditions are:

[0106] Chromatographic column: HP-5MS (60m×0.25mm×0.25μm) quartz capillary column; carrier gas: He; flow rate: 1mL / min; inlet temperature: 280°C; split ratio: 10:1; injection volume: 1 μL; temperature program:

[0107] Interface temperature: 280°C; ion source: EI; ionization energy: 70eV; ion source temperature: 230°C; quadrupole temperature: 150°C; solvent delay: 6min; scan range: 40~350amu.

[0108] The results of chromatographic analysis were as figure 1 as shown, figure 1 For the chromatographic an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com