Three-dimensional stranding, untwisting and cabling machine for large-length great-section high-voltage photoelectric composite submarine cable

A photoelectric composite and large cross-section technology, applied in the direction of cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of not being able to fully untwist, unable to solve its own torque, etc., to reduce the number of joints, reduce turnover, and ensure safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

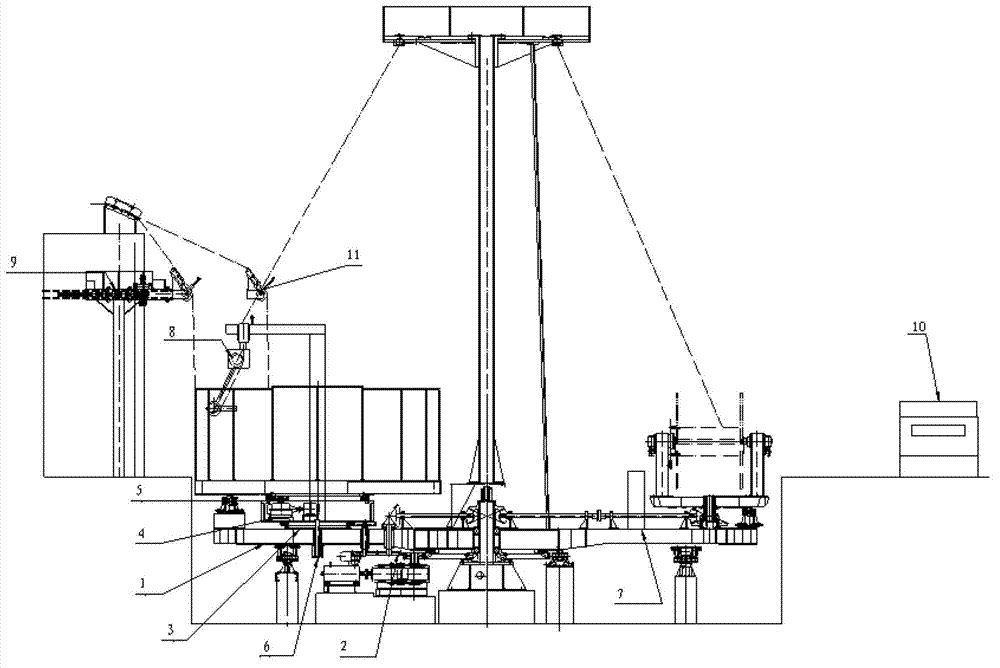

[0021] As shown in the accompanying drawings, the large-length, large-section high-voltage optoelectronic composite submarine cable three-dimensional twisting machine of the present invention includes a tray drive motor 2, a mechanical slewing bearing 3, a frequency conversion motor 4, an electrical slewing bearing 5, and a conductive device 6 , stranded body PLC system 7 or main PLC control system 10, untwisting system 8, cable arrangement device 9. The tray transmission motor 2 is transmitted to the large 8m tray through the bevel gear and the spur gear on the twisted turntable 1, and then the tray is rotated through the mechanical slewing bearing 5. The tray frequency conversion motor 4 is controlled by the conductive device 6 according to the signal of the linkage main PLC control system 10 or the single-action strand PLC control system 7, and the theoretical setting is obtained, and the tray rotation is realized by the electric slewing bearing 5. In the production process...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com