Constant-boiling dehydrating system used for producing maleic anhydride

A maleic anhydride and water pipe technology is applied in the field of azeotropic dehydration systems for the production of maleic anhydride, which can solve the problems of increasing enterprise costs, easy-to-corrode equipment, economic losses, etc., and achieve the effects of stable product quality, low processing costs, and strong strain performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

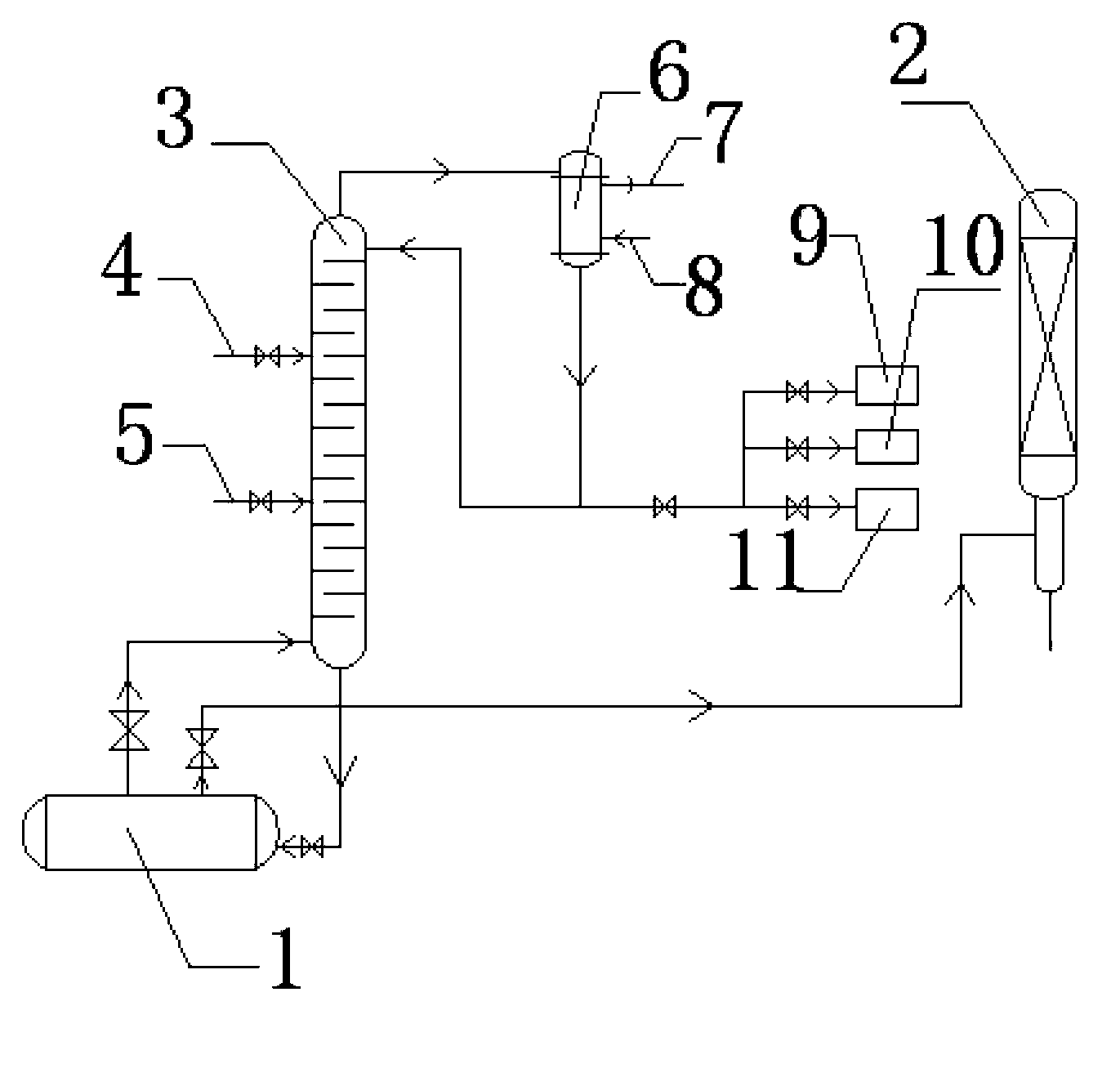

[0010] like figure 1 As shown, a kind of azeotropic dehydration system for the production of maleic anhydride of the present invention is characterized in that: it comprises a refining kettle 1, an azeotropic dehydration tower 3, and the azeotropic dehydration tower 3 is provided with an acid inlet pipe 4 and a thickened anhydride pipe 5. The refining kettle 1 is connected to the bottom of the azeotropic dehydration tower 3 through a pipeline and a valve is provided on the pipeline. The refining kettle 1 is connected to the solvent recovery tower 2 through a pipeline and a valve is also installed on the pipeline. The pipeline at the bottom of the dehydration tower 3 is connected and the pipeline is provided with a valve, and the constant boiling dehydration tower 3 is provided with an azeotropic condenser 6. Tank 11 is connected. The thickened anhydride pipe 5 is arranged in the middle of the azeotropic dehydration tower 3 . The azeotropic condenser 6 is provided with a circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com