Anti-condensation device of dry dust collector for high-humidity dust-containing air

A dry dust collector and anti-condensation technology, applied in chemical instruments and methods, dispersed particle separation, dispersed particle filtration, etc., can solve the problems of low dust removal efficiency, high filter replacement cost, high labor intensity, etc. Reduce operation and management costs and management difficulties, improve dust removal efficiency and dust recovery rate, and improve the effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

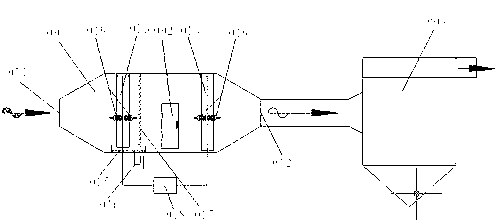

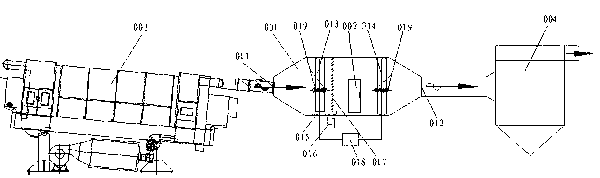

[0014] Example 1: The drum-type shred drying machine 003 in the shred workshop of the cigarette factory uses steam as the heating energy source. During the shred drying process, due to the boiling state of the shredded tobacco, the dust in the shredded tobacco is blown into the airflow, and the dust in the airflow is accompanied by The steam air flow is discharged, and sent into the air inlet 011 of the anti-condensation device of the high-humidity and dust-laden air dry dust collector of the present invention through the ventilation duct. In the water collection tray 015, it is discharged out of the device through the drain port 016. In order to prevent the condensed water from drifting with the air flow, a baffle 017 is installed behind the evaporator 013. The dried air flow passes through the condenser 014, and the cooled and dehumidified air is heated. Through the air outlet 012, it is sent to the subsequent bag filter 004 for dust removal. In order to prevent the dust in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com