Preparation method of polymer nanometer fiber bunch under independent state

A nanofiber and polymer technology, which is applied in the field of preparation of polymer nanofibers, can solve the problems of unreported PLLA nanofiber bundled porous materials and the like, and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1. Add 5 grams of PLLA into a round-bottomed flask filled with 100ml of tetrahydrofuran, and stir magnetically at 50°C for 2 hours to fully dissolve it to obtain a transparent and clear solution with a mass concentration of 5%, and then age it at 20°C for 1.5 hours.

[0023] 2. Transfer the solution to a low-temperature freezer at –20°C, and quench for 60 minutes to form a frozen liquid.

[0024] 3. Afterwards, add fresh distilled water to the freezing solution and transfer it to the refrigerator at 5°C. Change the fresh distilled water every 8 hours for 8 times, and remove the solvent tetrahydrofuran in the freezing solution by leaching.

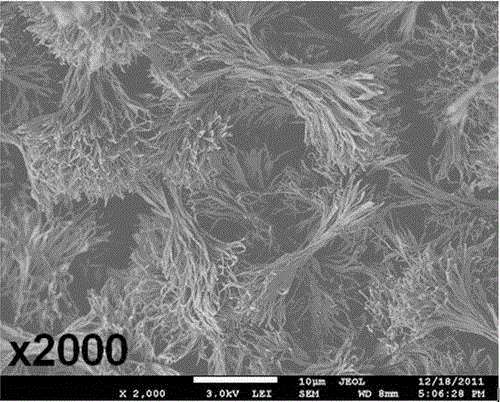

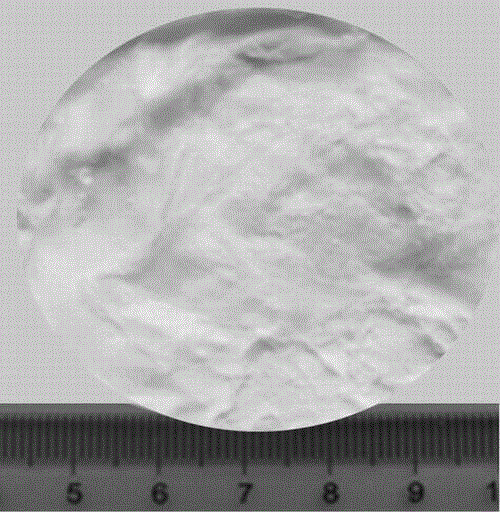

[0025] 4. Pour out the distilled water, freeze the sample at –23°C for 2 hours, then freeze-dry at –50°C to obtain PLLA bundled nanofibers, as shown in the attached figure 1 shown. The porous material composed of nanofiber bundles is shown in the attached figure 2 shown.

[0026] The nanofibers prepared in this example are presen...

Embodiment 2

[0028] 1. Add 2 grams of PLLA into a round-bottomed flask containing 100ml of dimethylformamide, stir at 65°C for 3 hours to fully dissolve it, and prepare a PLLA / dimethylformamide solution with a mass fraction of 5%. The solution was then aged at 10 °C for 2 h.

[0029] 2. Quench the aged PLLA / dimethylformamide solution at –40°C for 180 min to form a frozen liquid.

[0030] 3. After that, add fresh distilled water to the freezing solution and transfer it to the refrigerator at 8°C. Change the fresh distilled water every 8 hours, and change the water 6 times, and remove the dimethylformamide in the freezing solution by leaching.

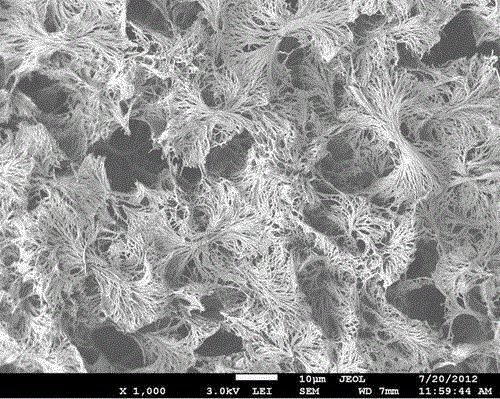

[0031] 4. Finally, pour out the distilled water, freeze at -23°C for 2 hours, and freeze-dry at -50°C to obtain PLLA nanofiber bundled porous materials, as shown in the attached image 3 shown.

[0032] The nanofibers prepared in this embodiment are in the form of bundles, the thickness of the fibers is 280 nanometers, the length is 41-48 microns, ...

Embodiment 3

[0034] 1. Add 5 grams of nylon 6 into a round-bottomed flask containing 100 ml of m-cresol, stir at 45 °C for 2.5 h to fully dissolve, and prepare a nylon 6 / m-cresol solution with a mass fraction of 5%.

[0035] 2. Aging the nylon 6 / m-cresol solution at 30°C for 120 minutes, and then quenching at 5°C for 5 minutes to form a frozen liquid.

[0036] 3. Afterwards, add fresh distilled water to the freezing solution and transfer it to the refrigerator at 8°C. Change the fresh distilled water every 8 hours, and change the water 7 times, and completely remove m-cresol by leaching.

[0037] 4. Finally, pour out the distilled water, freeze at -23°C for 2 hours, and freeze-dry at -50°C to obtain bundles of nylon 6 nanofibers. as attached Figure 4 shown.

[0038] The nanofibers prepared in this embodiment are in the form of bundles, the thickness of the fibers is 150-280 nanometers, the length is 5-10 microns, and the bundles have an arc of 30-50°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com