Substrate treatment device and substrate treatment method

A technology of a substrate processing device and a processing method, which is applied in the directions of gaseous chemical plating, coating, electrical components, etc., can solve the problem of affecting the heating efficiency of heating devices such as infrared lamps and reflectors, affecting the operation time of equipment and maintenance costs, shortening Service life and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

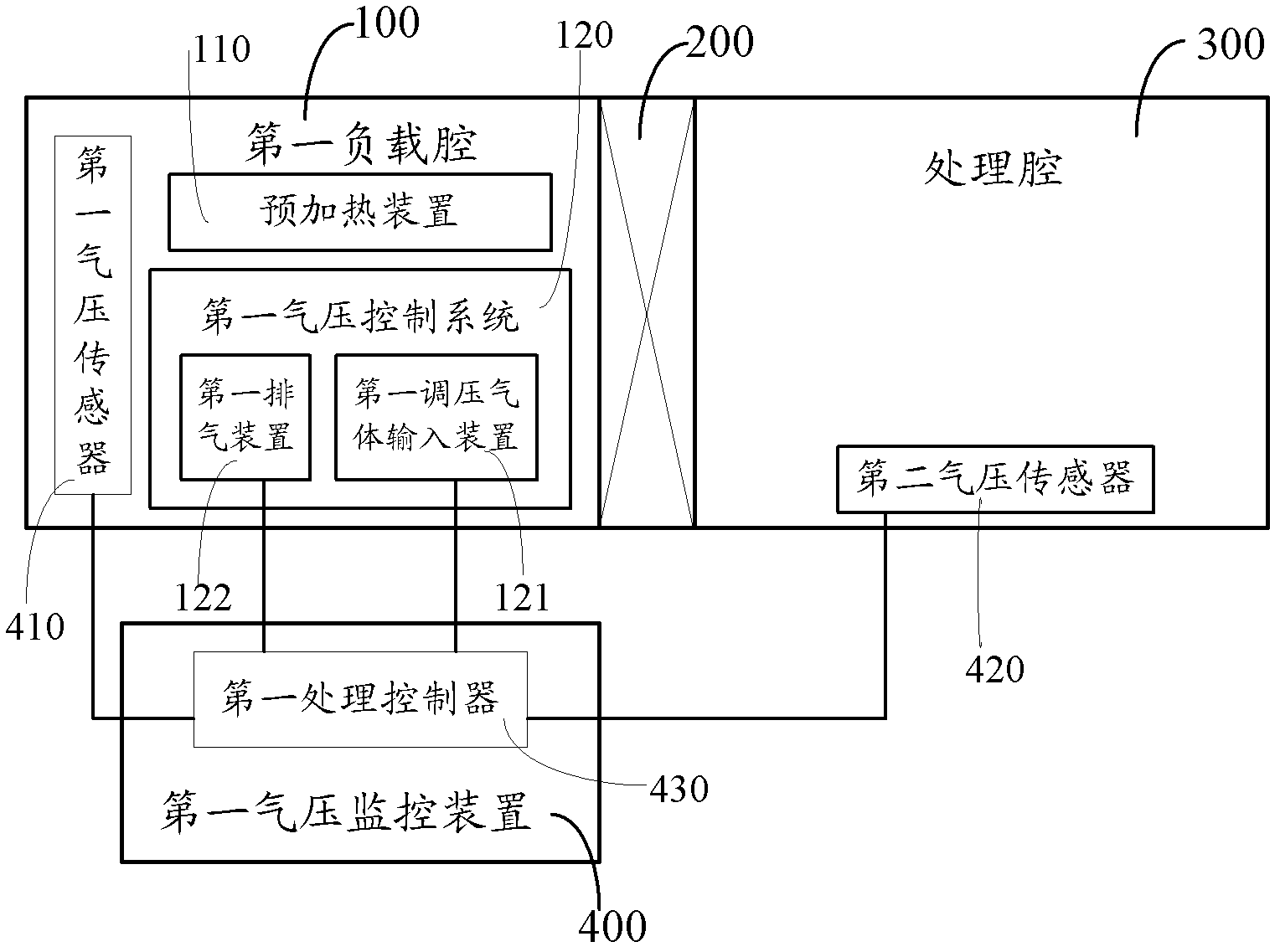

[0083] figure 1 is a schematic structural diagram of the substrate processing apparatus of this embodiment. Such as figure 1 As shown, the substrate processing apparatus described in this embodiment includes: a first load chamber 100, a first valve 200, a processing chamber 300 and a first air pressure adjustment unit, wherein the first valve 200 is set in the first Between the loading chamber 100 and the processing chamber 300, it is used to connect the first loading chamber 100 and the processing chamber 300; the first air pressure adjustment unit makes the first valve 200 open, the first The air pressure of the loading chamber 100 is greater than the air pressure of the processing chamber 300 .

[0084] Specifically, when the first valve 200 is opened, the pressure difference between the first loading chamber 100 and the processing chamber 300 is greater than 0 and less than or equal to 50mbar, such as: 0.5mbar, 25mbar, 50mbar, etc. Preferably, when the first valve 200 i...

Embodiment 2

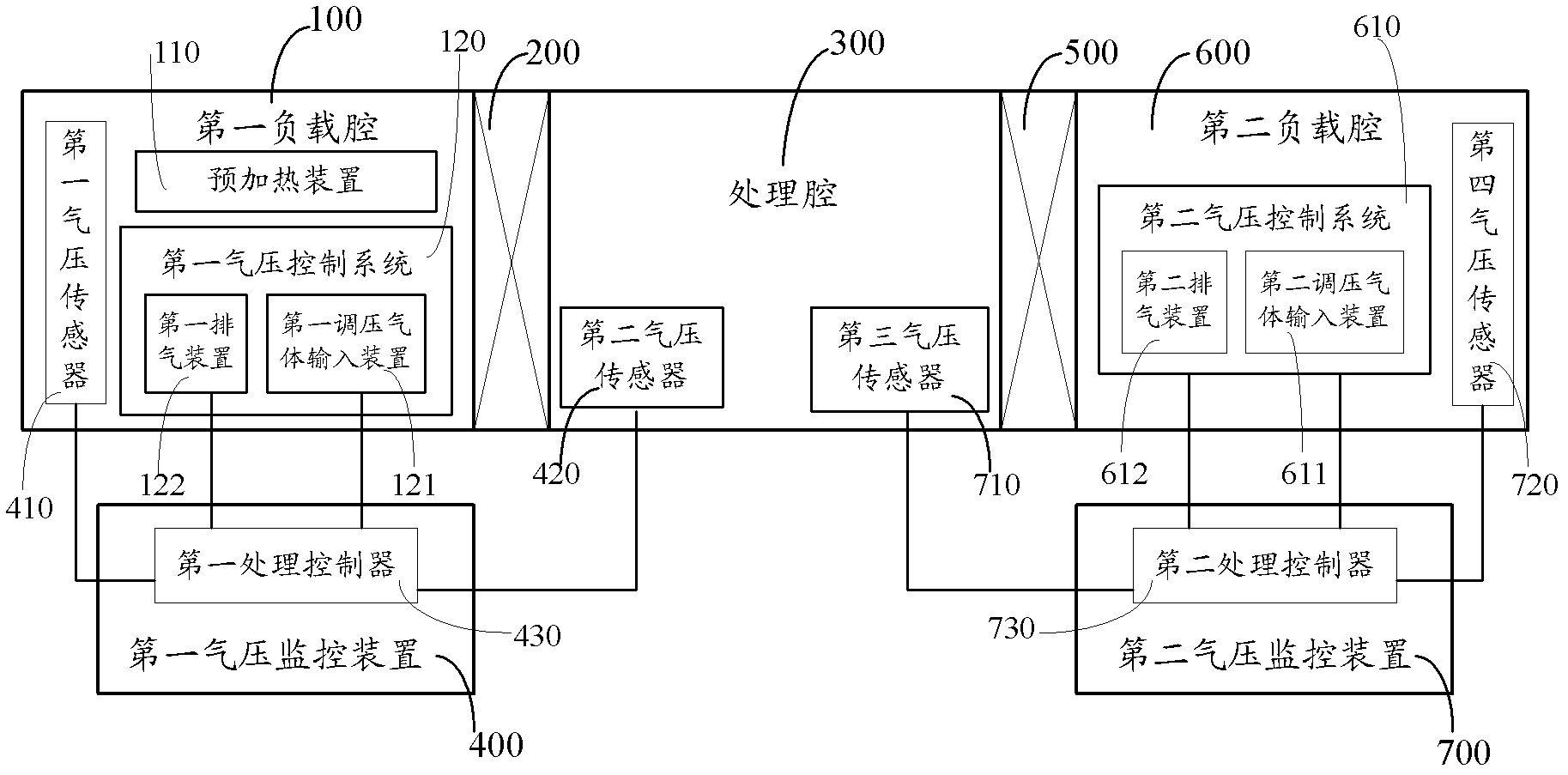

[0118] image 3 is a schematic structural diagram of the substrate processing apparatus of this embodiment. Compared with Embodiment 1, the substrate processing apparatus described in this embodiment further includes: a second valve 500, a second load chamber 600, and the first air pressure adjustment unit, wherein: the second valve 500 is set at the Between the processing chamber 300 and the second load chamber 600, used to connect the second load chamber 600 and the processing chamber 300; the first air pressure adjustment unit makes the first valve 200 open, the The air pressure of the first loading chamber 100 is greater than the air pressure of the processing chamber 300 .

[0119] In this embodiment, the first loading chamber 100 is a loading chamber and is only used for loading glass substrates; the second loading chamber 600 is an unloading chamber and is used for unloading glass substrates. The second loading chamber 600 has a cooling device (not shown) for cooling ...

Embodiment 3

[0146] Figure 5 is a schematic structural diagram of the substrate processing apparatus of this embodiment. Compared with Embodiment 2, the processing chamber 300 in the substrate processing apparatus described in this embodiment includes a first deposition chamber 310, a second deposition chamber 320, a third deposition chamber 330, and a fourth deposition chamber 340 arranged continuously , wherein: the first loading chamber 100 is connected to the first deposition chamber 310 through the first valve 200, the first deposition chamber 310 is connected to the second deposition chamber 320, and the second deposition chamber 320 is connected to the third deposition chamber 330, The third deposition chamber 330 is connected to the fourth deposition chamber 340 , and the fourth deposition chamber 340 is connected to the second load chamber 600 through the second valve 500 . It should be noted that, in other embodiments of the present invention, the processing chamber may also in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com