Compound disinfectant

A disinfectant and sodium carbonate technology, applied in the direction of disinfectant, biocide, animal repellent, etc., can solve the problems of strong corrosiveness of disinfectant, low corrosiveness, and non-environmental protection of disinfectant, so as to improve the disinfection effect and reduce the Less corrosive, effect of increasing solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] At normal temperature and pressure, under the condition of 500r / min magnetic stirring, add 0.2g of DICS to 95.85ml of water, after completely dissolving to obtain the initial disinfectant, add 0.3g of sodium carbonate and 0.05g of sodium tetraborate, and stir until completely dissolved , now the pH is 10, then, add 0.4g Triton X-100, 1.0g AES, 0.5g AOS, 1.5g polymerized propylene glycol-400 and 0.2g lauryl alcohol successively, stir until mixing evenly, obtain the A compound disinfectant, wherein the mass percentage of each component is DICS: 0.2%, sodium carbonate: 0.3%, sodium tetraborate: 0.05%, Triton X-100: 0.4%, AES: 1.0%, AOS: 0.5%, Polymerized Propylene Glycol-400: 1.5%, Lauryl Alcohol: 0.2%.

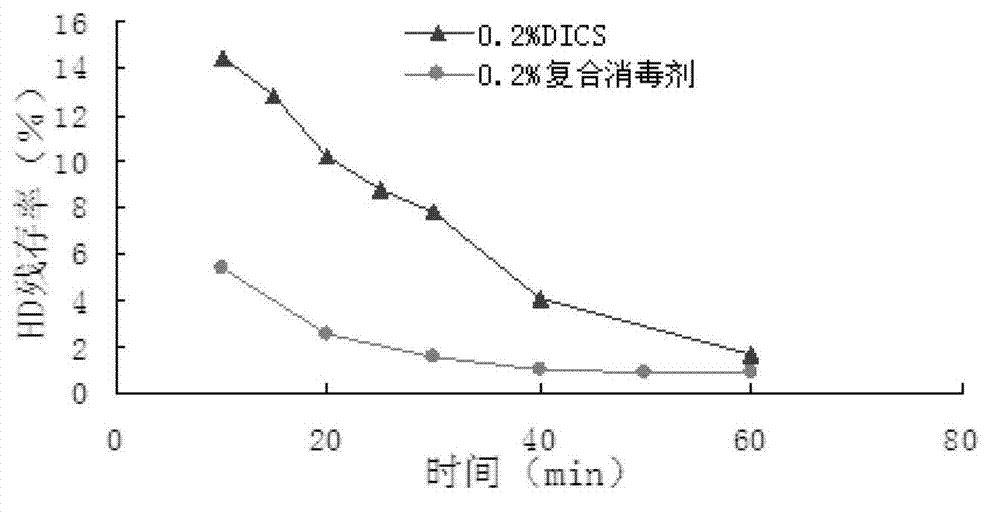

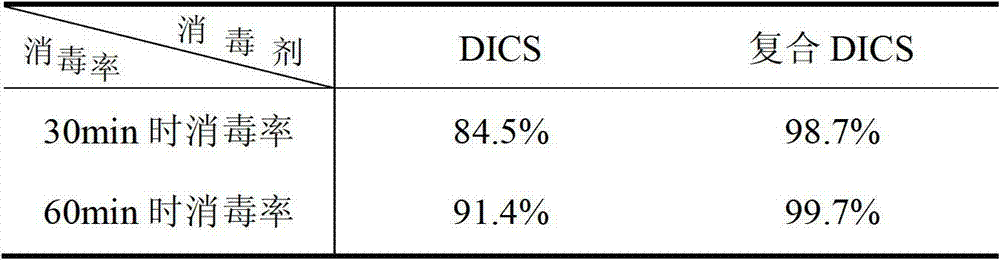

[0032] Carry out dynamic disinfection test to HD with described composite disinfectant:

[0033] Fix the 50mL three-necked bottle on the electric stirrer, use a super constant temperature water bath to control the reaction temperature to 25°C, adjust the stirring speed o...

Embodiment 2

[0036] At normal temperature and pressure, under the condition of 500r / min magnetic stirring, add 3g of DICS to 90.3ml of water, after completely dissolving to obtain the initial disinfectant, add 1.2g of sodium carbonate and 0.2g of sodium tetraborate, stir until completely dissolved, Now the pH is 10, then, add 0.4g Triton X-100, 1.0gAES, 1.5gAOS, 2.0g polymerized propylene glycol-400 and 0.4g lauryl alcohol successively, stir until mixed evenly, obtain a kind of composite Disinfectant, wherein the mass percentage of each component is DICS: 3%, sodium carbonate: 1.2%, sodium tetraborate: 0.2%, Triton X-100: 0.4%, AES: 1.0%, AOS: 1.5%, polymerized propylene glycol- 400: 2.0%, lauryl alcohol: 0.4%.

[0037] Static disinfection test was carried out on HD with the composite disinfectant, that is, dynamic measures such as stirring were not used in the disinfection process.

[0038] Add 10 μL HD into a small test tube with a micro-syringe, and weigh the quality of HD. Slowly add...

Embodiment 3

[0042] Corrosion comparison of compound disinfectant, DICS disinfectant and three-in-two disinfectant to metal:

[0043] First, prepare various disinfectants separately:

[0044] Composite disinfectant: the composite disinfectant prepared in Example 2;

[0045] DICS disinfectant: an aqueous solution with a mass fraction of DICS of 3%;

[0046] Three-in-two disinfectant solution: it is the supernatant liquid of three-in-two saturated solution.

[0047] Then, carry out the corrosion test according to the following steps:

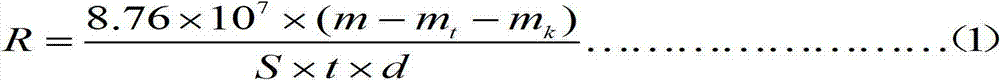

[0048]① Soak stainless steel, carbon steel, copper and aluminum metal sheets in surface-active detergent for 10 minutes, fully degrease and wash them; use 120-grit water sandpaper to grind off both sides and surrounding areas of the metal sheets Then rinse the oxide layer with tap water; degrease again with anhydrous acetone; dry it in a 50°C incubator for 1 hour, and weigh it as a sample after the temperature drops to room temperature; weigh each piece of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com